Preparation method of a three-dimensional bouquet-structured α-molybdenum carbide@carbon with high-efficiency light-to-heat conversion properties

A light-to-heat conversion and molybdenum carbide technology, which is applied in the direction of carbon preparation/purification, chemical instruments and methods, tungsten/molybdenum carbides, etc., can solve the problems of harsh preparation conditions, affecting application effects, and easy spontaneous combustion, etc., to reduce Material cost, good reproducibility, effect of reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

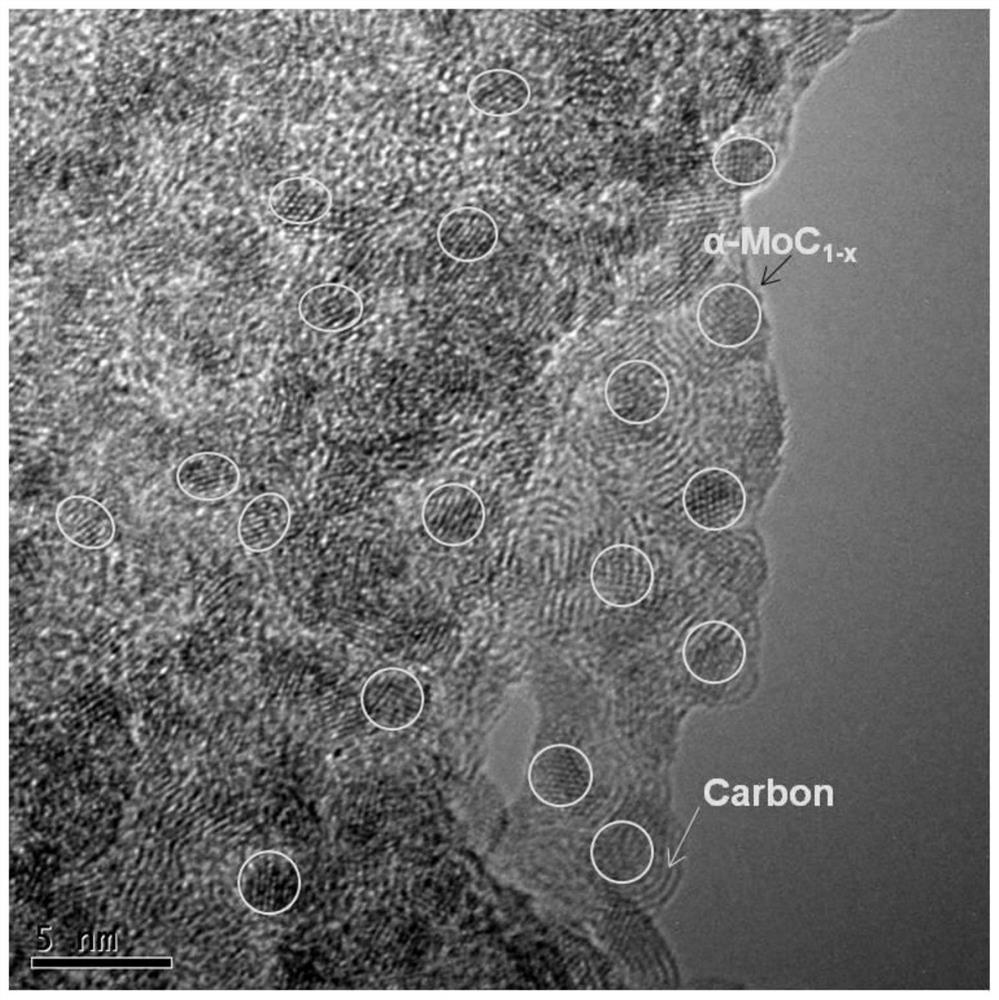

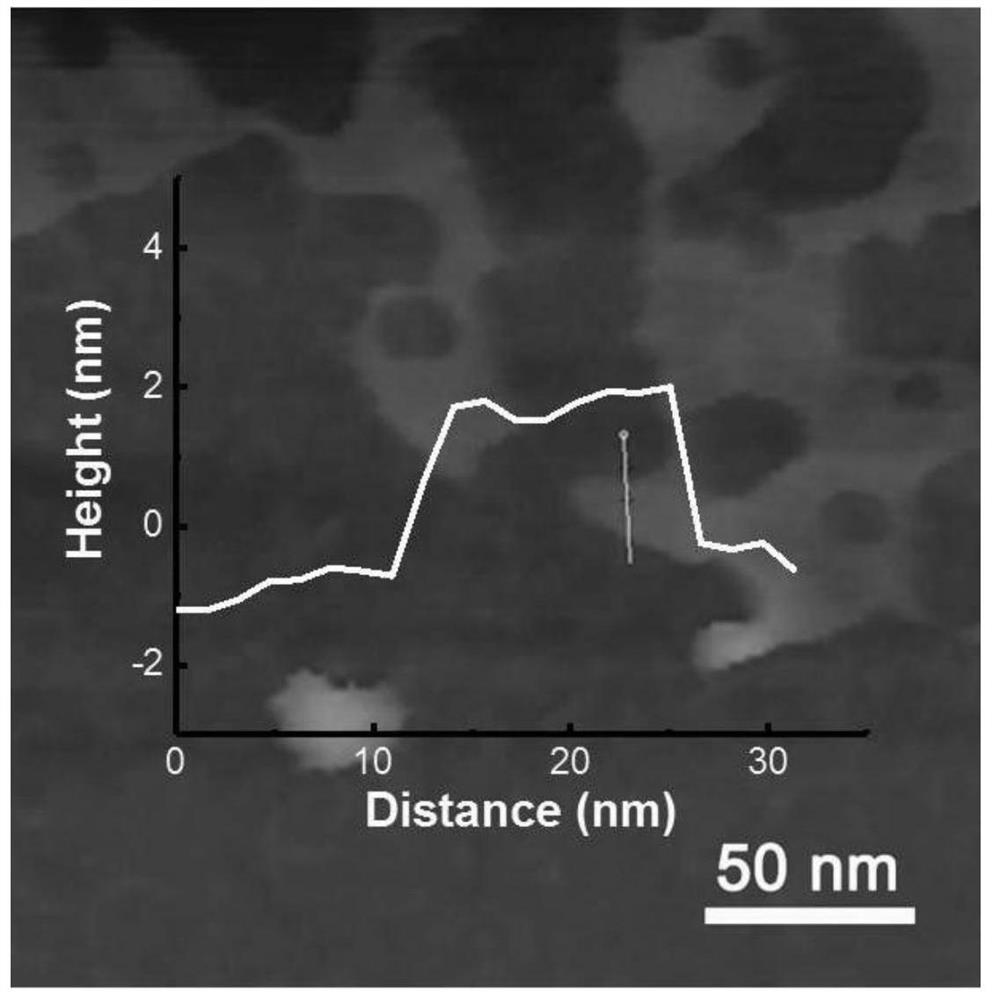

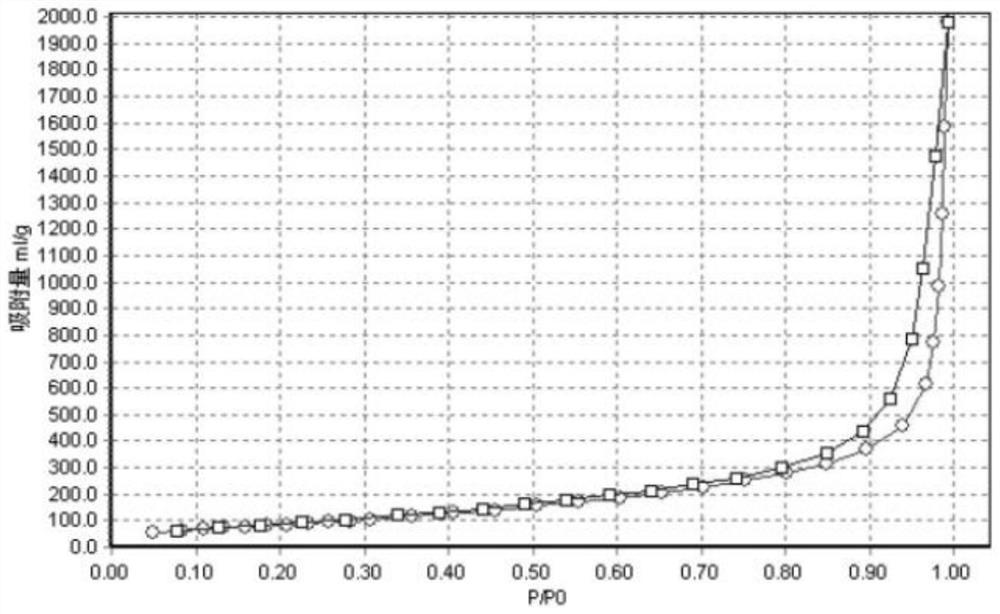

[0021] Specific implementation mode 1: This implementation mode is a preparation method of a three-dimensional bouquet structure α-molybdenum carbide@carbon with high-efficiency light-to-heat conversion characteristics, which is specifically carried out according to the following steps:

[0022] 1. Add molybdenum powder and aqueous hydrogen peroxide solution with a mass fraction of 30% to the liquid alcohol in turn, stir for 24h~48h, then add melamine, continue stirring for 0.5h~48h, and then centrifuge at a speed of 3000rpm~5000rpm for 5min~ 10min, dry at last, obtain molybdenum precursor;

[0023] The mass of described molybdenum powder and mass fraction are 1g:(0.5mL~50mL);

[0024] The mass of described molybdenum powder and the volume ratio of liquid alcohol are 1g:(10mL~500mL);

[0025] The mass ratio of described molybdenum powder and melamine is 1:(1~50);

[0026] 2. Mechanically mix the molybdenum precursor obtained in step 1 with urea, then place the mixture in a c...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the liquid alcohol described in step 1 is one or a mixture of absolute ethanol, ethylene glycol and isopropanol. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying temperature in step 1 is 40°C. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com