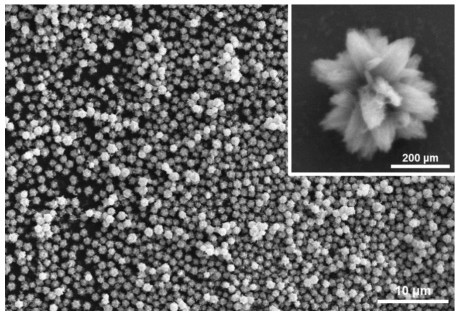

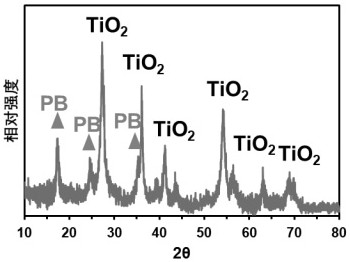

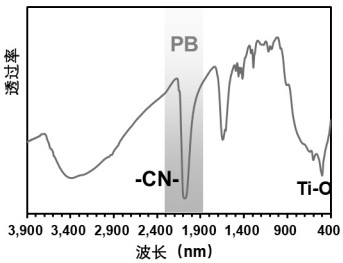

Titanium dioxide and prussian blue orderly assembled mesocrystal nano material and preparation method thereof

A Prussian blue and titanium dioxide technology, applied in the field of materials, can solve the problems that limit the practicality of MOF-INC, and achieve the effects of easy access to equipment and materials, uniform size, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Completely dissolve 0.12g potassium ferrocyanide and 3.8g polyvinylpyrrolidone in dilute hydrochloric acid solution, stir for 30min in a magnetic stirrer with a rotating speed of 500 rpm until the solid is completely dissolved, and obtain solution A.

[0037](2) Add 0.682g of titanium sulfate to the above solution A, stir for 5min, sonicate for 25min, place it in a 100ml autoclave, and hydrothermally react at 80℃ for 24h.

[0038](3) Wash 3 times with 60ml alcohol and 60ml deionized water, andoThe orderly assembled composite material was obtained by drying in an oven of C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com