Shield muck unfired hollow brick and preparation method thereof

A hollow brick and shield slag technology is applied in the field of shield slag-free burning hollow bricks and their preparation, which can solve the problems of unsuitable shield slag and difficulty in breaking shield slag, and achieve sustainable utilization and conservation of resources. The effect of cost and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

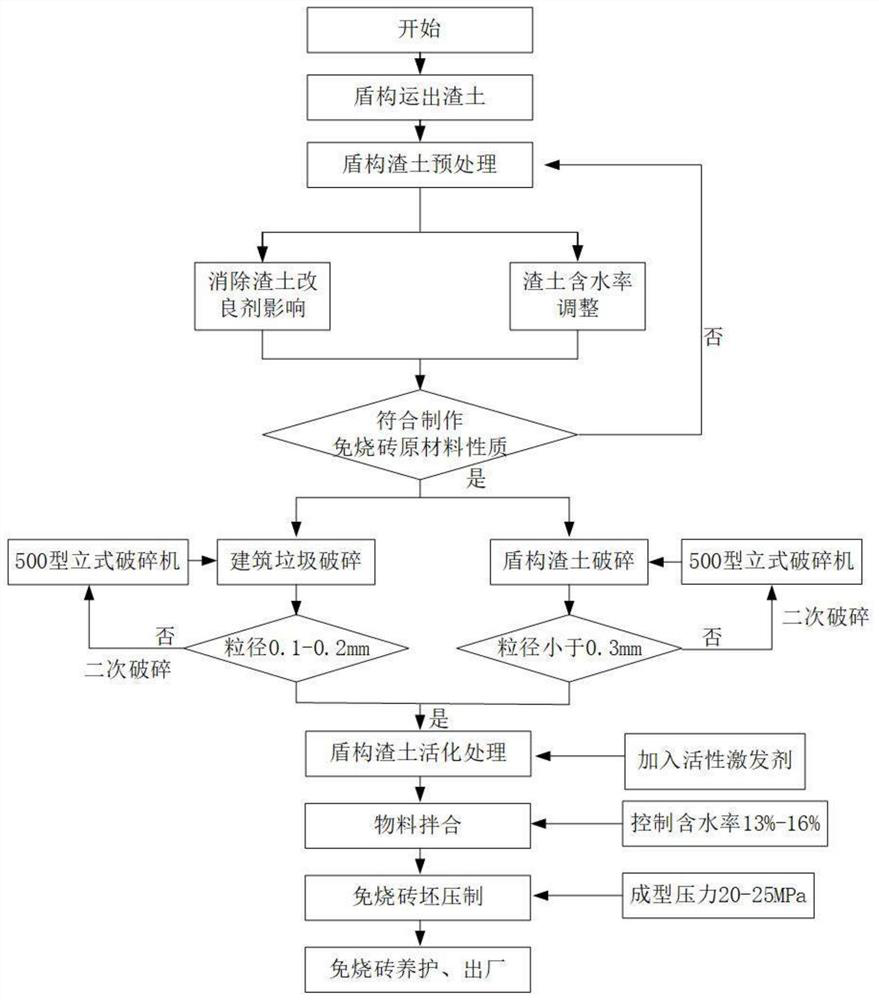

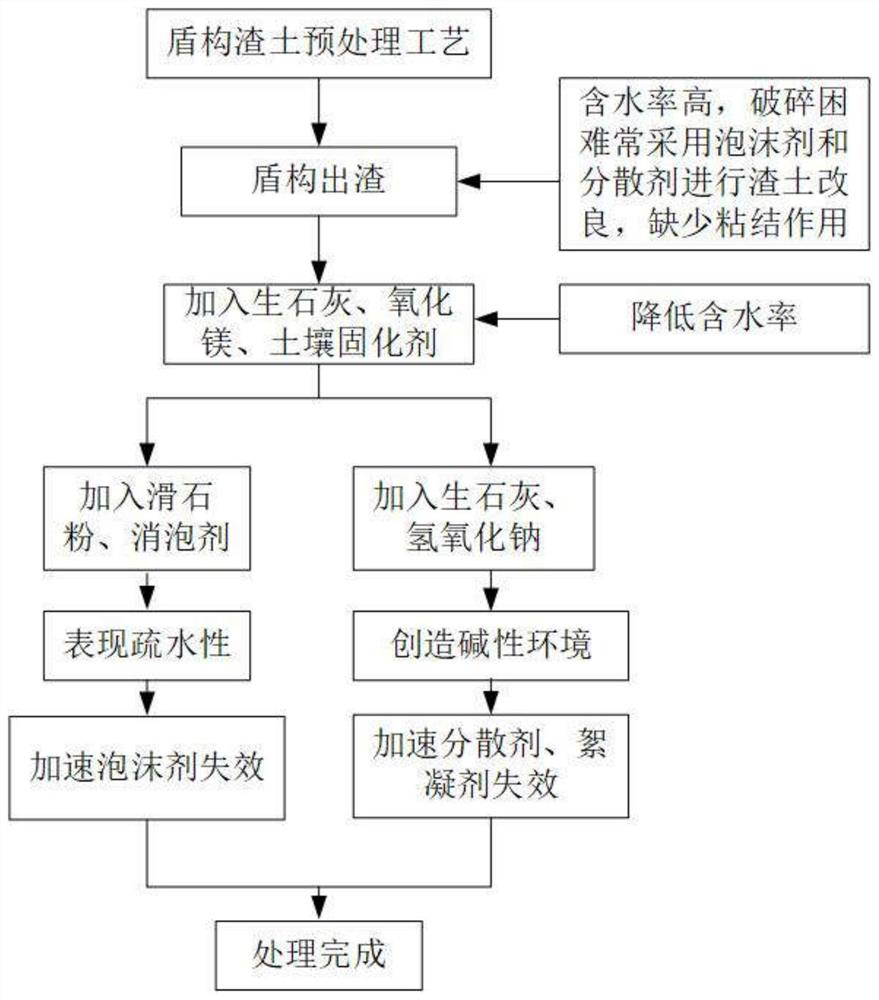

Method used

Image

Examples

Embodiment 1

[0054] The weight ratio is 40 parts of shield muck, 10 parts of construction waste, 20 parts of machine-made sand, 5 parts of fly ash, 15 parts of cement, 4 parts of quicklime, 5 parts of soil curing agent, and sodium lignosulfonate for water reduction. 2 parts of agent, 3 parts of water glass, 2 parts of activator, 1 part of magnesium oxide, 2 parts of polysiloxane defoamer, 0.5 part of sodium hydroxide, 4 parts of talcum powder and 13 parts of water, according to the free The preparation plan of fired hollow bricks is to make unfired hollow bricks. After 28 days of curing according to the ratio, the unfired hollow bricks are tested for compressive strength, softening coefficient, and relative moisture content.

[0055] The natural moisture content of the shield muck soil sample was tested to be 40%, which is slightly higher than the liquid limit, and the soil is relatively moist. The plasticity index is 17.6, and the liquidity index is 0.86. Judging from the plastic state in...

Embodiment 2

[0060] Different from Example 1, the distribution ratio (weight ratio) of each component is: 50 parts of shield muck, 10 parts of construction waste, 20 parts of machine-made sand, 5 parts of fly ash, 12 parts of cement, 3 parts of quicklime, soil 4 parts of curing agent, 2 parts of polysiloxane defoamer, 0.5 parts of sodium hydroxide, 3 parts of talcum powder, 2 parts of sodium lignosulfonate water reducer, 2 parts of water glass, 2 parts of activator, magnesium oxide 0.5 parts, 13 parts of water.

[0061] After testing, the average compressive strength of the prepared shield slag unfired hollow brick is 11.2MPa, the strength after soaking in water for four days is 9.6MPa, the softening coefficient is 0.86, and the relative moisture content is 29.3%.

Embodiment 3

[0063] Different from Example 1, the distribution ratio (weight ratio) of each component is: 60 parts of shield muck, 20 parts of construction waste, 10 parts of machine-made sand, 10 parts of fly ash, 10 parts of cement, 3 parts of quicklime, soil 3 parts of curing agent, 1 part of polysiloxane defoamer, 0.5 parts of sodium hydroxide, 4 parts of talcum powder, 2 parts of sodium lignosulfonate water reducer, 4 parts of water glass, 2 parts of activator, magnesium oxide 1 part, 15 parts water.

[0064] According to the test, the average compressive strength of the prepared shield slag unfired hollow brick is 7.2MPa, the strength after soaking in water for four days is 5.8MPa, the softening coefficient is 0.81, and the relative moisture content is 34.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com