Welding flux for quickly welding heterogeneous ceramics at low temperature

A fast welding and soldering technology, applied in the field of welding, can solve problems such as direct welding, and achieve the effects of high-efficiency welding, thermal stress relief, and low welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

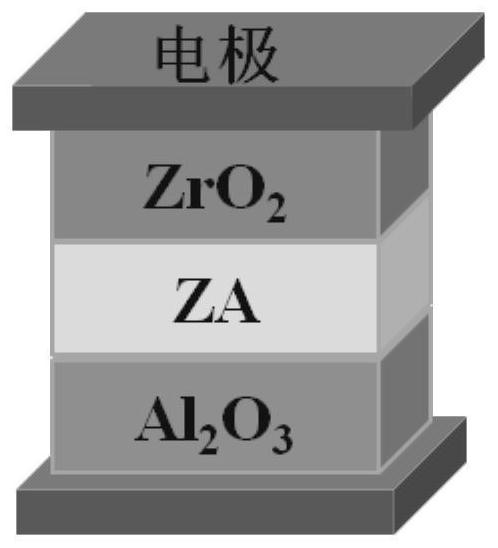

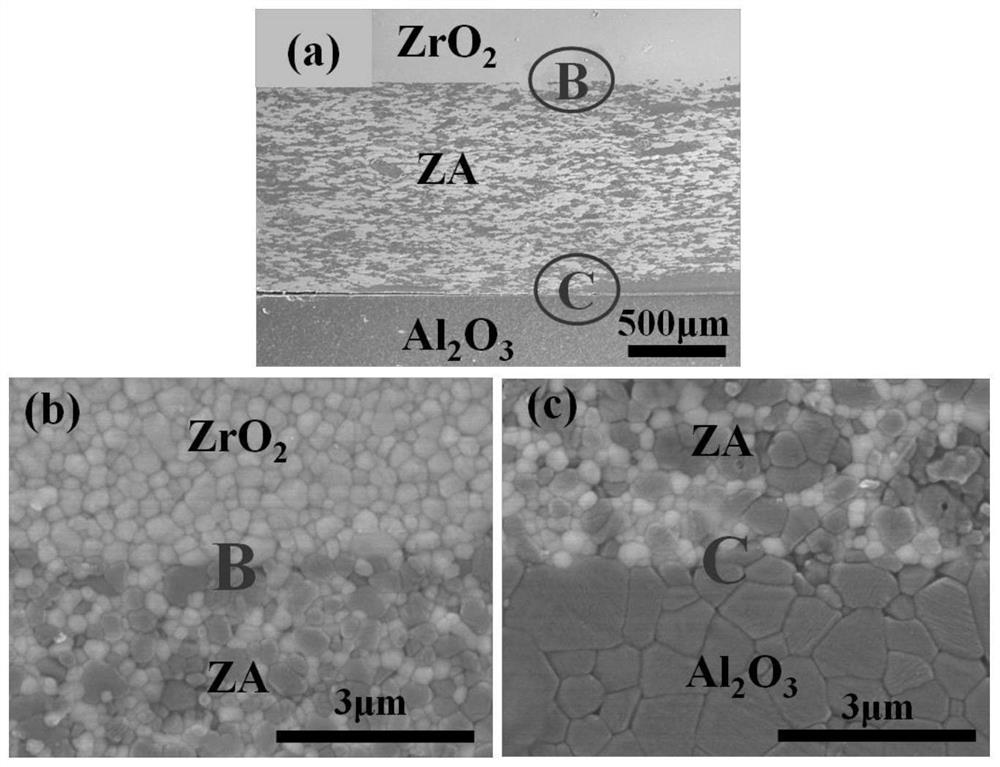

Method used

Image

Examples

Embodiment 1

[0019] a) mixing 3% yttrium oxide-stabilized zirconia powder with a mass fraction of 1% magnesia-doped alumina powder at a mass ratio of 50%:50%, and then compressing the resulting mixed powder, Sinter at 1500°C to obtain the desired solder.

[0020] b) polishing the surfaces of the solder, zirconia and alumina ceramics obtained in step a) to 10 μm;

[0021] c) the surface of the sample obtained in step b) is closely attached together, and a pressure of 2MPa is applied;

[0022] d) heating the sample obtained in step c) to 1200°C;

[0023] e) Apply an electric field intensity of 800V / cm to the sample obtained in step d), and a current density of 5mAmm –2 , and keep it for 30s to complete the welding between the samples.

[0024] Conclusion: By using the solder with a mass ratio of zirconia and alumina of 50%:50%, the high-efficiency welding of zirconia and alumina is realized, and the welding effect is good.

Embodiment 2

[0026] a) The mass fraction is 3% yttrium oxide stabilized zirconia powder and the mass fraction is 1% magnesia doped alumina powder according to the mass ratio of 20%:80%, and then the resulting mixed powder is pressed into shape , Sintered at 1450 ° C to obtain solder.

[0027] b) polishing the surfaces of the solder, zirconia and alumina ceramics obtained in step a) to 5 μm;

[0028] c) the surface of the sample obtained in step b) is closely attached together, and a pressure of 2MPa is applied;

[0029] d) heating the sample obtained in step c) to 1200°C;

[0030] e) Apply an electric field intensity of 800V / cm to the sample obtained in step d), and a current density of 5mAmm -2 , and keep it for 30s to complete the welding between the samples.

[0031] Conclusion: By using the solder with a mass ratio of zirconia and alumina of 20%:80%, the high-efficiency welding of zirconia and alumina is realized, and the welding sample with high solder-alumina interface strength is...

Embodiment 3

[0033] a) The mass fraction is 2% calcium oxide stabilized zirconia powder and the mass fraction is 1% magnesia-doped alumina powder and mixed uniformly at a mass ratio of 40%:60%, and then the resulting mixed powder is pressed into shape , Sintered at 1550 ° C to obtain solder.

[0034] b) polishing the surfaces of the solder, stabilized zirconia and alumina ceramics obtained in step a) to 1 μm;

[0035] c) The surface of the sample obtained in step b) is closely attached together, and a pressure of 1 MPa is applied;

[0036] d) heating the sample obtained in step c) to 1300°C;

[0037] e) Apply an electric field intensity of 750V / cm to the sample obtained in step d), and a current density of 10mAmm -2 , and keep it for 10s to allow welding between samples.

[0038] Conclusion: By using the solder with a mass ratio of zirconia and alumina of 40%:60%, the high-efficiency welding of zirconia and alumina is realized, and the welding effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com