Photocatalytic self-cleaning non-woven fabric, preparation method and mask prepared from photocatalytic self-cleaning non-woven fabric

A non-woven fabric and self-cleaning technology, which is applied in the field of masks, can solve the problems of low protective efficiency of ordinary masks, achieve the effects of improving photocatalytic effect, strong antibacterial ability, and enhancing filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] In a specific embodiment, the present invention provides a method for preparing a photocatalytic self-cleaning non-woven fabric, and the preparation method specifically includes the following steps:

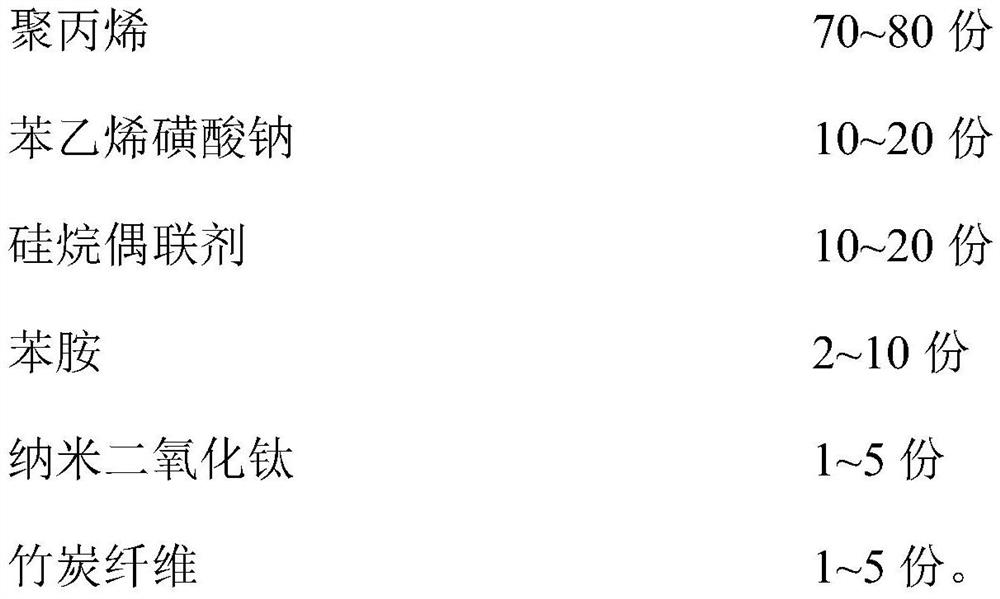

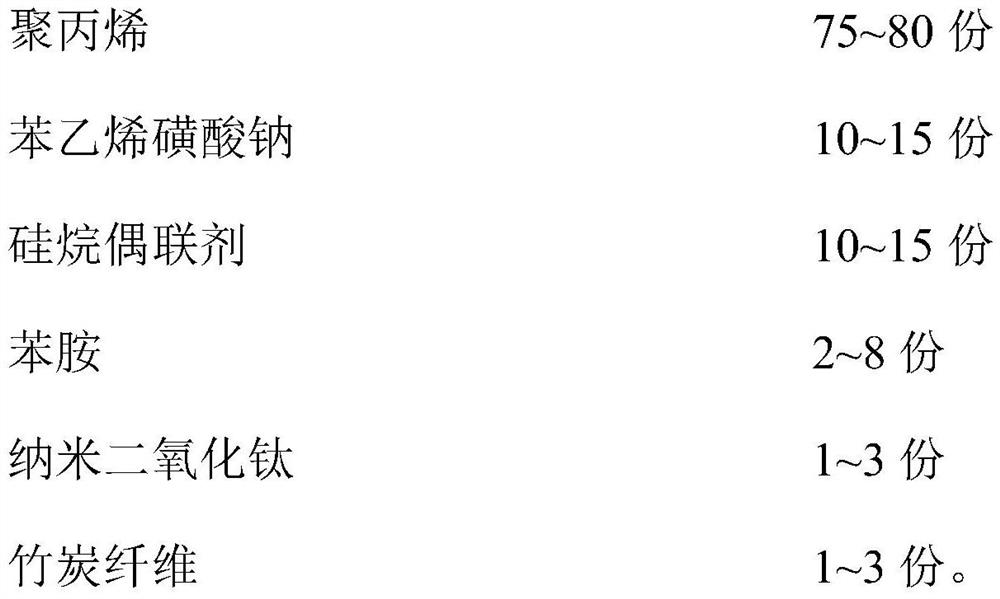

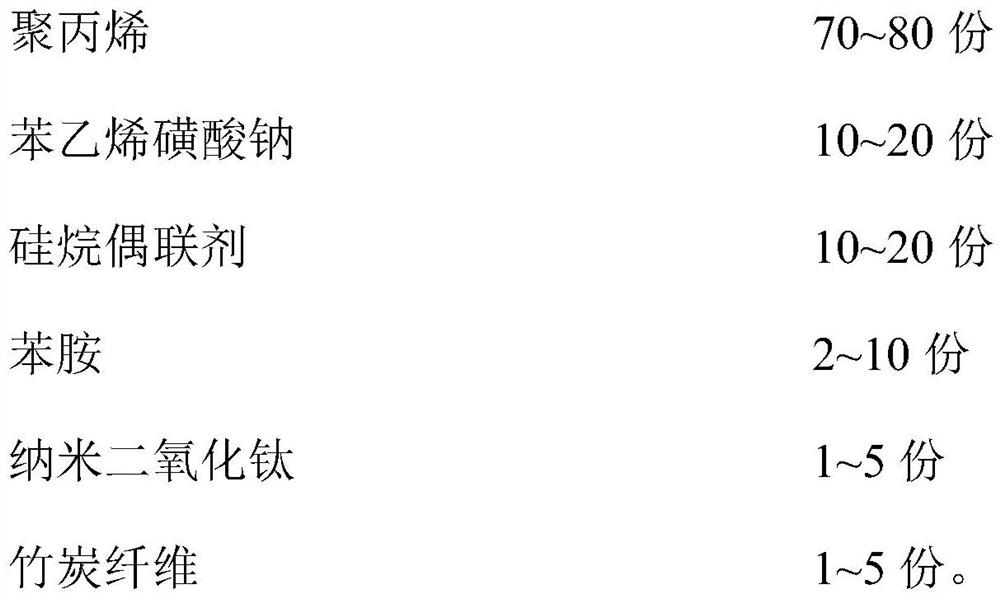

[0068] (1) Weigh the following components in parts by weight: 70-80 parts of polypropylene, 10-20 parts of sodium styrene sulfonate, 10-20 parts of silane coupling agent, 2-10 parts of aniline, 1-20 parts of nano-titanium dioxide 5 parts and 1-5 parts of bamboo charcoal fiber;

[0069] Mix the weighed polypropylene, sodium styrene sulfonate and silane coupling agent, heat in a water bath at 50-60°C for 2-3 hours, and then irradiate with ultraviolet light at 4-5W / cm for 10-20 minutes to obtain a polypropylene mixture ;

[0070] After mixing the polypropylene mixture with the bamboo charcoal fiber, stir once at 40-50°C for 0.5-1h; finally add aniline and nano-titanium dioxide to mix, and stir again at 40-50°C for 10-20min to obtain the spinning liquid, and the spinning sol...

Embodiment 1

[0075] This embodiment provides a method for preparing a photocatalytic self-cleaning non-woven fabric. The preparation method specifically includes the following steps:

[0076] (1) Take each component of following parts by weight respectively: 70 parts of polypropylene, 10 parts of sodium styrene sulfonate, 10 parts of silane coupling agent, 2 parts of aniline, 1 part of nano-titanium dioxide and 1 part of bamboo charcoal fiber;

[0077] Mix the weighed polypropylene, sodium styrene sulfonate and silane coupling agent, heat in a water bath at 50°C for 3 hours, and then irradiate with ultraviolet rays with a light intensity of 4W / cm for 20 minutes to obtain a polypropylene mixture;

[0078] Mix the polypropylene mixture with the bamboo charcoal fiber and stir once at 40°C for 1 hour; finally add aniline and nano-titanium dioxide to mix, then stir again at 40°C for 20 minutes to obtain the spinning solution, and let the spinning solution stand for 1 hour reserve;

[0079] (2)...

Embodiment 2

[0084] This embodiment provides a method for preparing a photocatalytic self-cleaning non-woven fabric. The preparation method specifically includes the following steps:

[0085] (1) Take each component of following parts by weight respectively: 72 parts of polypropylene, 12 parts of sodium styrene sulfonate, 12 parts of silane coupling agent, 3 parts of aniline, 2 parts of nano-titanium dioxide and 2 parts of bamboo charcoal fiber;

[0086] Mix the weighed polypropylene, sodium styrene sulfonate and silane coupling agent, heat in a water bath at 52°C for 2.8 hours, and then irradiate with ultraviolet light at a light intensity of 4.2W / cm for 18 minutes to obtain a polypropylene mixture;

[0087] Mix the polypropylene mixture with the bamboo charcoal fiber and stir once at 42°C for 0.9h; finally add aniline and nano-titanium dioxide to mix, and stir again at 42°C for 18min to obtain the spinning solution, which is left to stand Standby after 1.2h;

[0088] (2) The spinning so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com