Anti-floating anchor rod pile test device and test method

An anti-floating anchor rod and test device technology, which is applied in the field of anchor piles, can solve the problems that the pull-out test characteristics of anti-floating anchor piles cannot be fully obtained, and are susceptible to electromagnetic interference, etc., and achieve strong environmental adaptability and anti-interference ability Strong, high data measurement accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

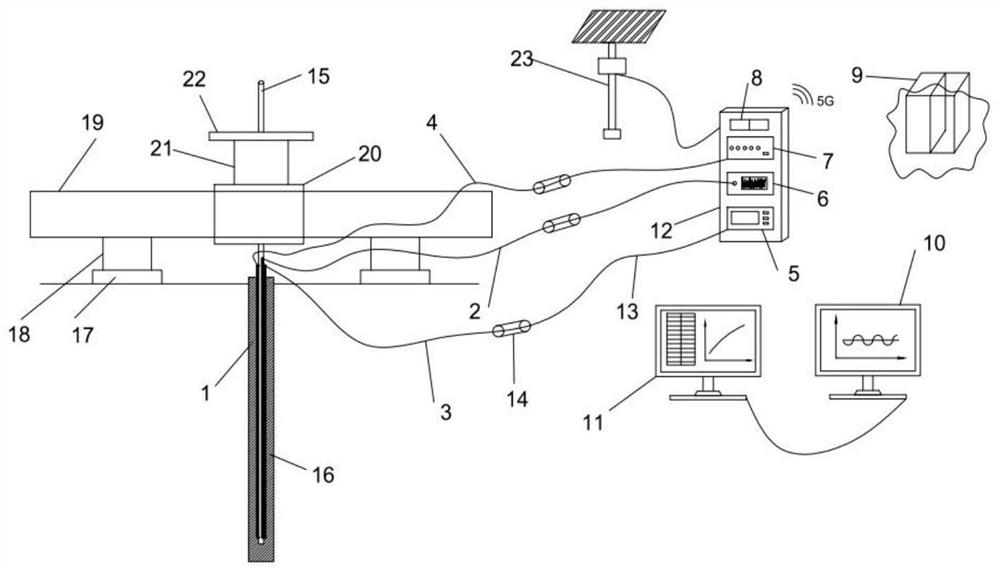

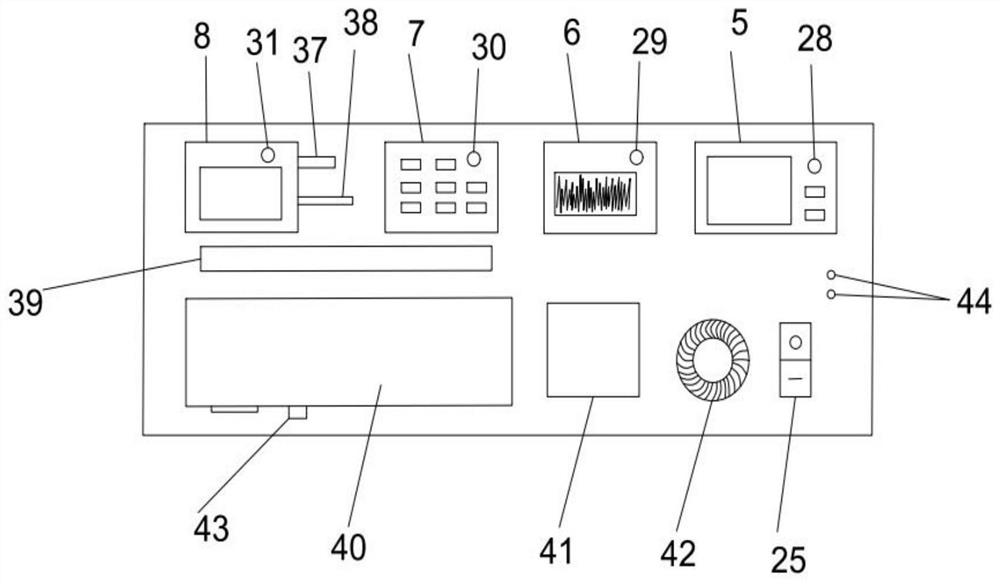

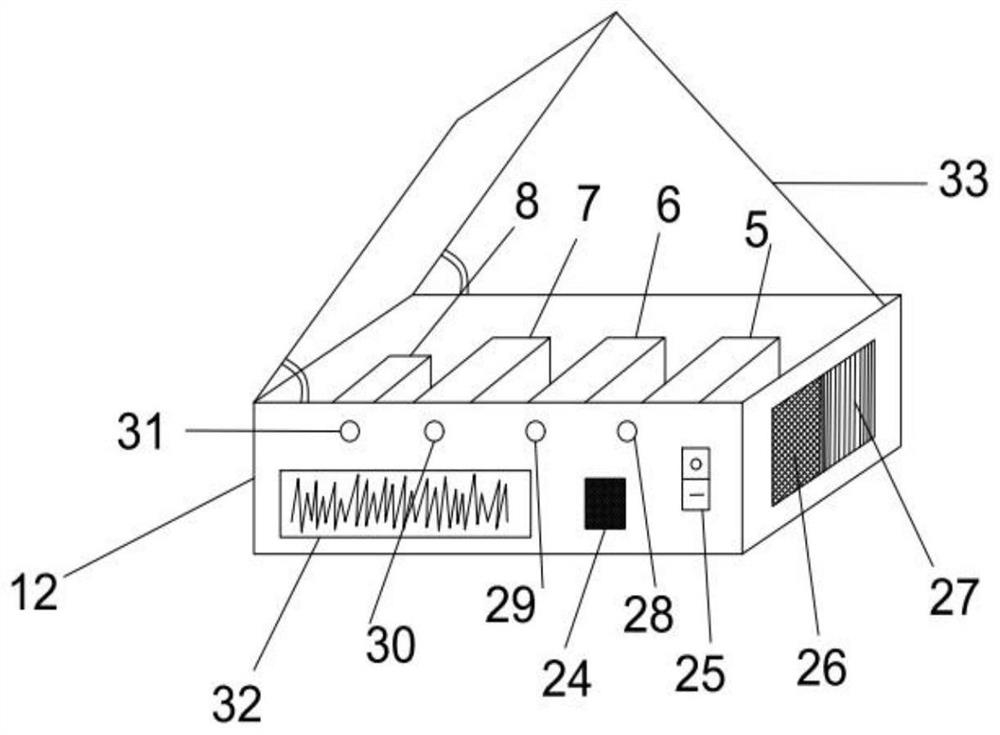

[0046] Such as Figure 1 to Figure 5As shown, the anti-floating anchor pile test device of the present invention includes an anti-floating anchor pile 1, a sensing component, a temperature and humidity sensing system 8, a data acquisition system, a data transmission system, a data processing and analysis system 10, and a monitoring result display system 11. Loading system and solar panel 23; specifically:

[0047] Sensing components include 0.9mm first strain sensing fiber 2, 2.0mm second strain sensing fiber 3, temperature sensing fiber 4; data acquisition system includes BOTDA data acquisition system 5, fiber grating data acquisition system 6 and DTS data acquisition System 7; the anti-floating anchor pile 1 is a cast-in-place anchor pile, and a hole is drilled on site by a piling machine, and then concrete is poured in the hole to form an anchor body 16, and then the anchor rod 15 is lowered into the grouted hole once , and then perform secondary grouting to finally form t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com