Solution processing series quantum dot light emitting diode based on doped connection layer and manufacturing method of light emitting diode

A quantum dot luminescence and solution processing technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor connection layer properties and limited selection, and achieve improved aqueous solution properties, improved wettability, and improved deposition. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

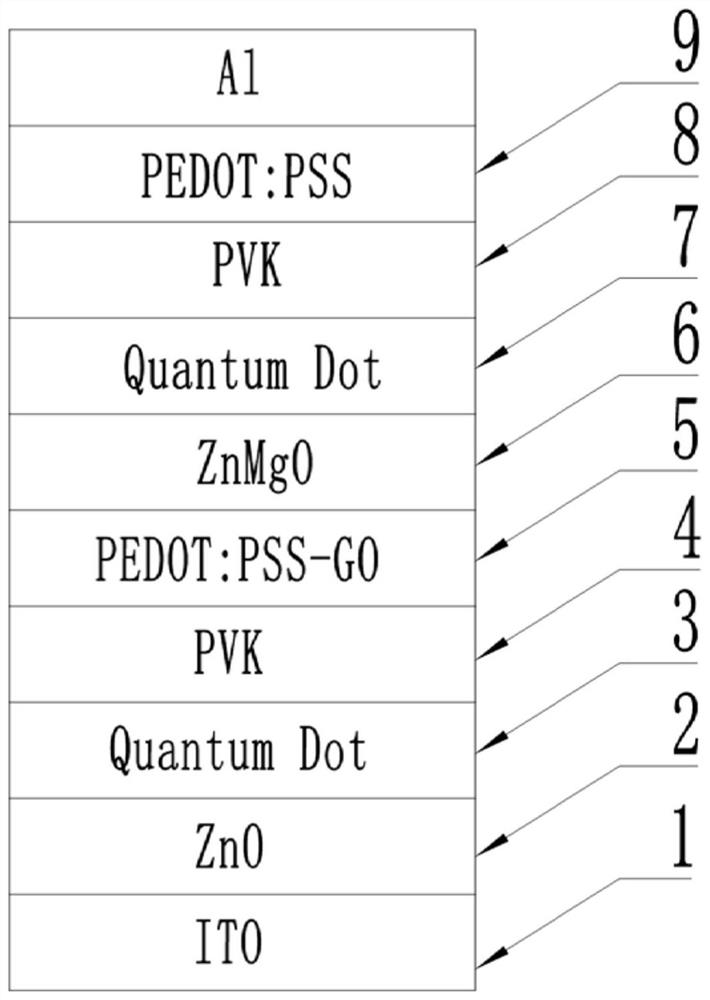

[0046] A solution-processed tandem quantum dot light-emitting diode based on a doped connection layer, basically as attached figure 1 Shown: Includes bottom device and top device. The bottom device includes a cathode 1 , a first electron injection layer 2 , a first quantum dot light-emitting layer 3 , a first hole transport layer 4 and a first hole injection layer 5 which are stacked sequentially from bottom to top. The top device includes a second electron injection layer 6 , a second quantum dot light-emitting layer 7 , a second hole transport layer 8 , a second hole injection layer 9 and an anode which are stacked sequentially from bottom to top. The first hole injection layer 5 of the bottom device and the second electron injection layer 6 of the top device are laminated, and the first hole injection layer 5 and the second electron injection layer 6 are used as the solution processing doping connection layer of the quantum dot light-emitting diode in series .

[0047] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com