Electrical porcelain product manufacturing process

A product manufacturing and electric porcelain technology, applied in the field of electric porcelain product manufacturing process, can solve the problem of high cost, achieve the effect of improving strength, reducing cost and omitting polishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

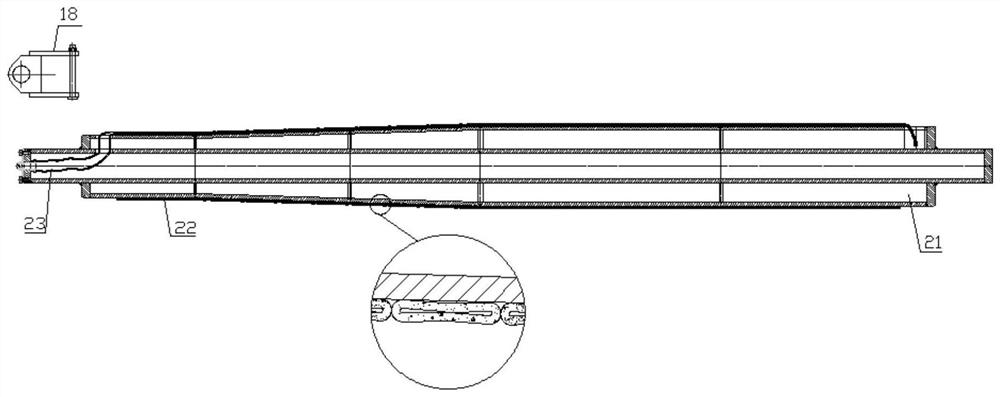

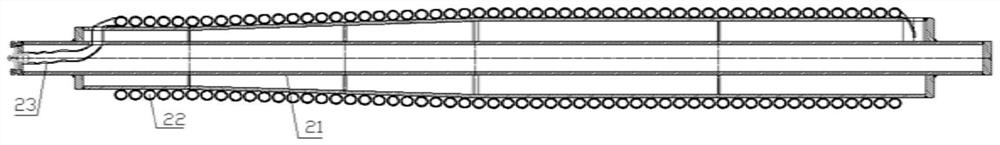

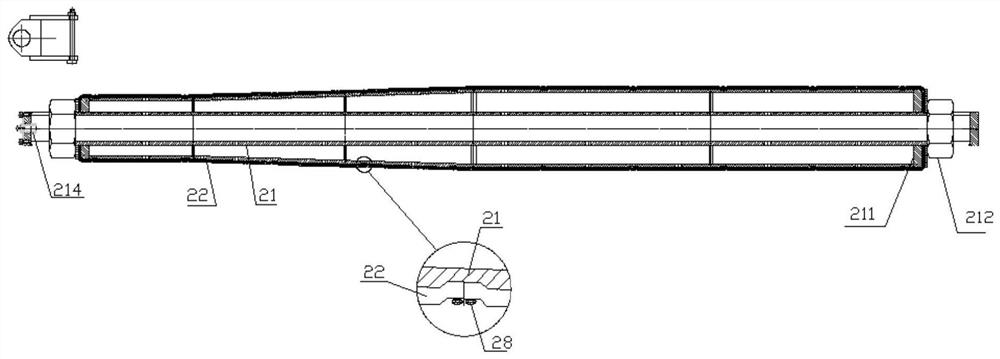

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] A manufacturing process for electric porcelain products, the manufacturing process of the present invention is used to produce electric porcelain products of 110kV and below, including:

[0035] 1) According to the formula requirements, the raw materials for making electric porcelain products are put into a ball mill for wet ball milling to make a slurry state;

[0036] 2) Use a spray dryer to dehydrate the raw material in the slurry state at high temperature, and make a powder whose particle size and water content meet the standard requirements;

[0037] 3) Press the qualified powder into blanks of required size and shape through isostatic pressing technology;

[0038] 4) Falling the blank, and clamping the fallen blank on a universal horizontal CNC lathe for turning;

[0039] 5) After processing the blank, keep it in a sleeping state and perform horizontal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com