Preparation method of basalt fibers

A basalt fiber and basalt technology, which is applied in glass manufacturing equipment, manufacturing tools, inorganic raw material rayon and other directions, can solve the problems of low tensile strength of basalt fiber, restrict the promotion of basalt fiber, etc., and achieve less waste and less environmental pollution. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

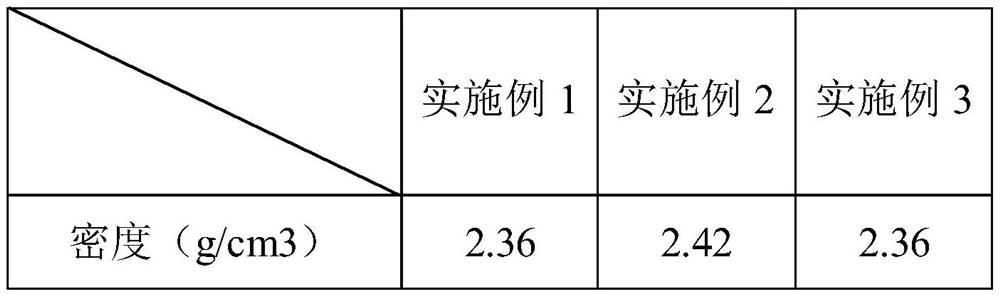

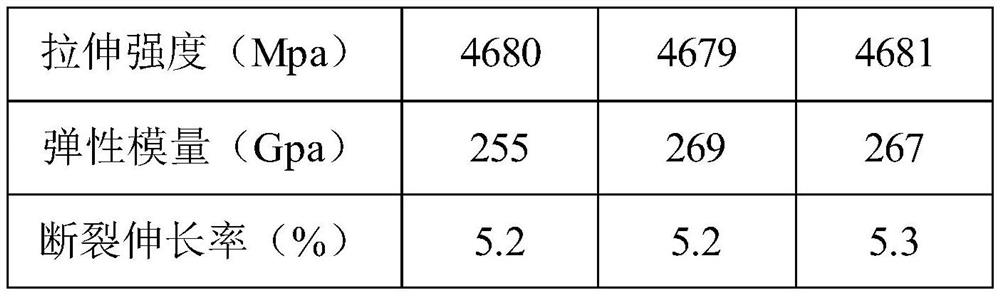

Embodiment 1

[0027] A kind of preparation method of basalt fiber, comprises the following steps:

[0028] (1) Pulverize the natural basalt ore and pass through a 100-200 mesh screen to obtain basalt ore powder, add the basalt ore powder to a phosphoric acid solution with a mass concentration of 50% and soak for 15 minutes, filter out and wash with water after the treatment is completed After reaching neutrality, put it into a sodium hydroxide solution with a mass concentration of 20% for soaking treatment for 2 minutes. After the treatment is completed, filter it out and wash it with water until it is neutral, then dry it at 120°C for later use;

[0029] (2) Add the above-mentioned basalt ore powder into the furnace, raise the temperature to 850°C under the protection of nitrogen, and then add a certain amount of carbon powder. The weight ratio of basalt ore powder to carbon powder is 50:1, and continue to heat up to 1400 ℃ to get the basalt solution, keep it warm for 15 minutes, and then ...

Embodiment 2

[0035] A kind of preparation method of basalt fiber, comprises the following steps:

[0036] (1) Pulverize the natural basalt ore and pass through a 100-200 mesh screen to obtain basalt ore powder, add the basalt ore powder to a phosphoric acid solution with a mass concentration of 55% and soak for 20 minutes, filter out and wash with water after the treatment is completed After reaching neutrality, put it into a sodium hydroxide solution with a mass concentration of 15% for soaking treatment for 2 minutes. After the treatment is completed, filter it out and wash it with water until it is neutral, then dry it at 120°C for later use;

[0037] (2) Add the above-mentioned basalt ore powder into the furnace, raise the temperature to 800°C under the protection of nitrogen, then add a certain amount of carbon powder, the weight ratio of basalt ore powder to carbon powder is 50:1, and continue to heat up to 1400°C ℃ to get the basalt solution, keep it warm for 12 minutes, and then fl...

Embodiment 3

[0043] A kind of preparation method of basalt fiber, comprises the following steps:

[0044] (1) Pulverize the natural basalt ore and pass through a 100-200 mesh screen to obtain basalt ore powder, add the basalt ore powder to a phosphoric acid solution with a mass concentration of 40% and soak for 10 minutes, filter out and wash with water after the treatment is completed After reaching neutrality, put it into a sodium hydroxide solution with a mass concentration of 12% for soaking treatment for 2 minutes. After the treatment is completed, filter it out and wash it with water until it is neutral, then dry it at 120°C for later use;

[0045] (2) Add the above-mentioned basalt ore powder into the furnace, raise the temperature to 880°C under the protection of nitrogen, then add a certain amount of carbon powder, the weight ratio of basalt ore powder to carbon powder is 45:1, and continue to heat up to 1400 ℃ to get the basalt solution, keep it warm for 15 minutes, and then flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com