Chemical augmented injection system for improving injectivity of oil displacement polymer

A systematic and chemical technology, applied in drilling compositions, chemical instruments and methods, mining fluids, etc., can solve the problems of reducing polymer adsorption, poor stability, weak adsorption force, etc., and achieve the effect of strong adsorption stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

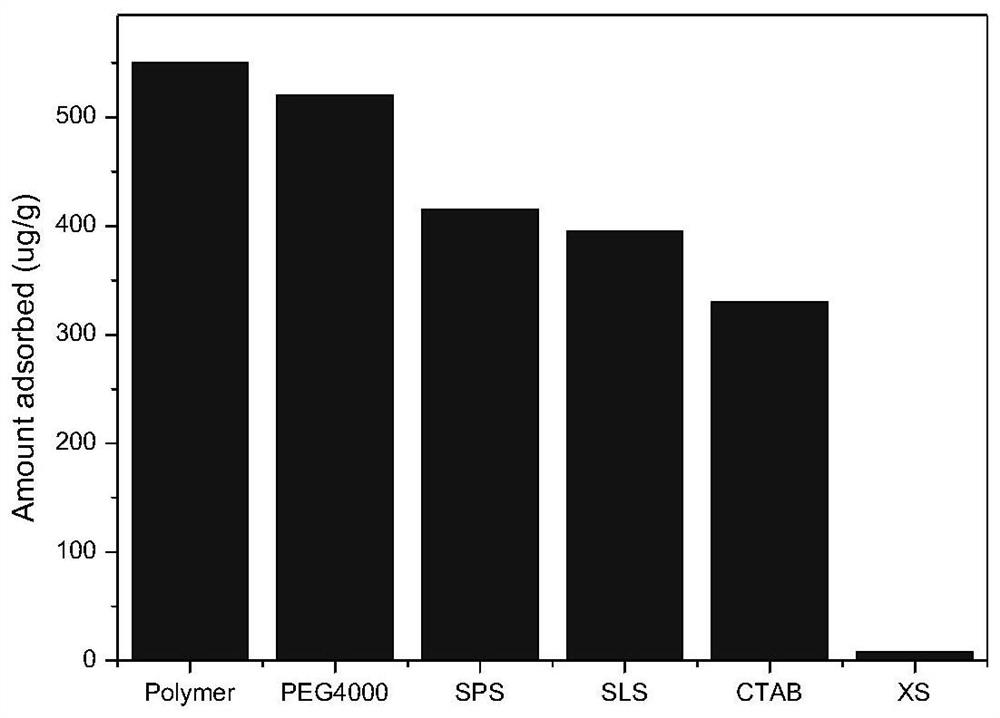

Problems solved by technology

Method used

Image

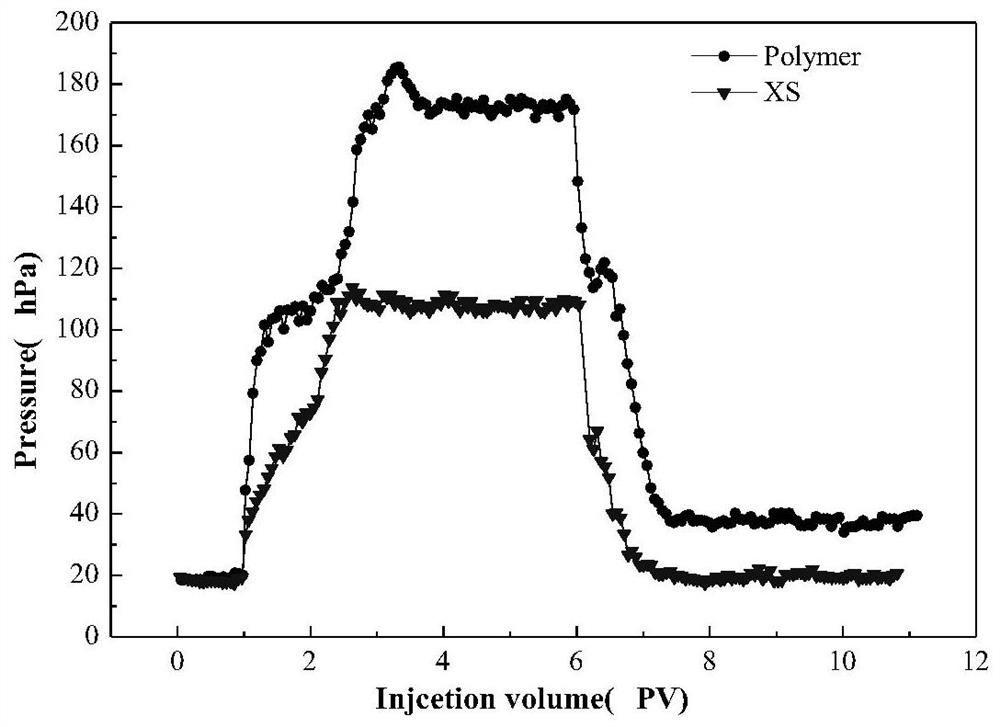

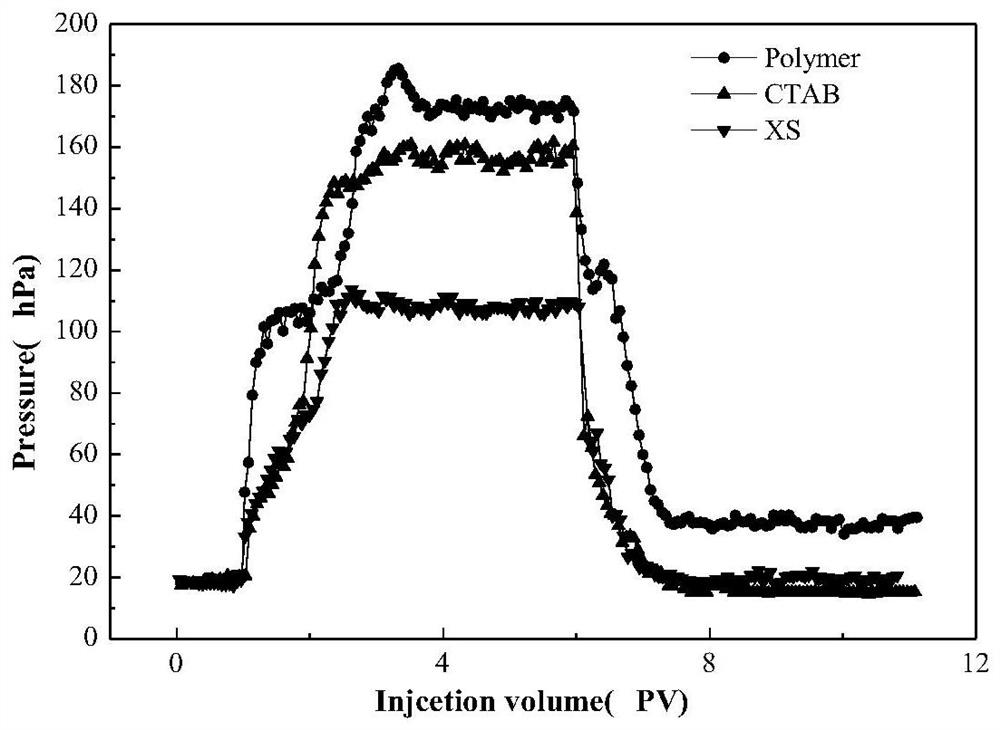

Examples

Embodiment Construction

[0029] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0030] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0031] 1. Preparation of chemical injection system

[0032] The organosilicon sacrificial agent used in this embodiment is triethoxyoctylsilane, and the auxiliary agent is a mixture of N-methyldiethanolamine and petroleum sulfonate. In the auxiliary agent, the mass percent concentration of N-methyldiethanolamine is 90%, the mass percent concentration of petroleum sulfonate is 10%. Compound the organosilicon sacrificial agent and the auxiliary agent according to the mass ratio of 70:30. The specific steps are: first prepare the aqueous solution of the auxiliary agent, wherein the mass fraction of N-methyldiethanolamine is 9%, the mass fraction of petroleum sulfonate The fraction is 1%, and then triethoxyoctylsilane is added to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com