Tungsten argon arc welding method and welding equipment for preventing weld seam oxidation

A technology of argon tungsten arc welding and welding method, which is applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of reverse oxidation of weld seam, reduce the mechanical properties of weld seam, turbulent flow of inert protective gas, etc., and achieve anti- Oxidation protects weld seam oxidation, ensures welding quality, and avoids the effect of weld seam oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

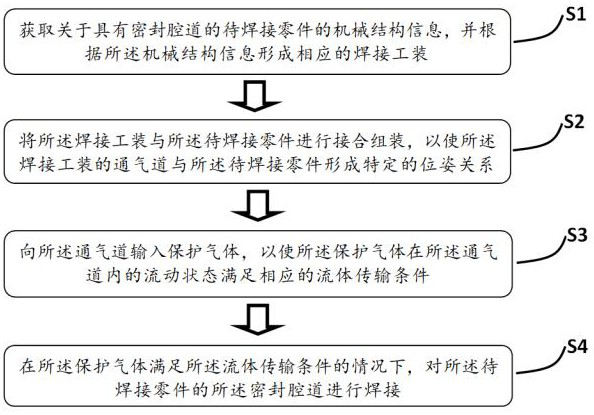

[0062] refer to figure 1 , figure 1 It is a schematic flow chart of a welding method of argon tungsten arc welding for preventing weld seam oxidation provided by the present invention. The argon tungsten arc welding method for preventing weld seam oxidation comprises the following steps:

[0063] Step S1, obtaining information about the mechanical structure of the part to be welded with a sealed cavity, and forming a corresponding welding tool according to the mechanical structure information;

[0064] Step S2, joining and assembling the welding tool and the part to be welded, so that the air passage of the welding tool and the part to be welded form a specific pose relationship;

[0065] Step S3, inputting protective gas into the air channel, so that the flow state of the protective gas in the air channel meets the corresponding fluid transmission conditions;

[0066] Step S4, under the condition that the shielding gas satisfies the fluid transmission condition, welding th...

Embodiment 2

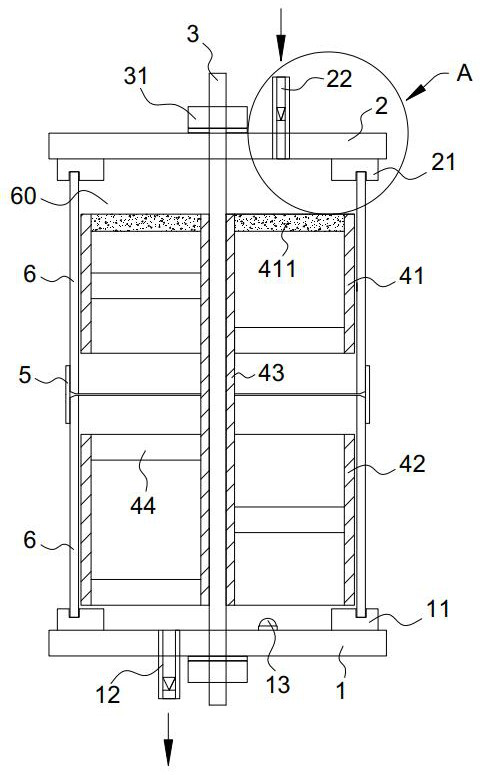

[0112] refer to Figure 2 to Figure 5 , The embodiment of the present invention provides a gas tungsten arc welding tool for preventing weld seam oxidation. The welding tool is suitable for the welding operation of the pipe wall of a thin-walled tubular test piece with a large diameter to form a sealed cavity.

[0113] The welding tooling includes a chassis 1, an end cover 2, a tensioning assembly, a mesh piece 4, an adhesive tape 5, and the like.

[0114] Wherein, the chassis 1 is provided with a first sealing ring 11 and an exhaust port 12, the size of the first sealing ring 11 matches the size of the end of the tubular test piece 6, and the exhaust port 12 is located inside the first sealing ring 11 .

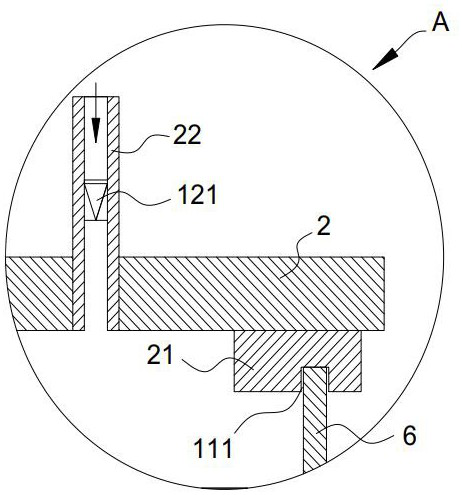

[0115] The end cover 2 is provided with a second sealing ring 21 and an air inlet 22, the size of the second sealing ring 21 is also adapted to the size of the end of the tubular test piece 6, and the air inlet 22 is located inside the second sealing ring 21 . The outside...

Embodiment 3

[0124] refer to Figure 6 and Figure 7 , The embodiment of the present invention provides a gas tungsten arc welding tool for preventing weld seam oxidation. The welding tool is suitable for the welding operation of the pipe wall of a thin-walled tubular test piece with a large diameter to form a sealed cavity. The structure of the welding tool of this embodiment is basically the same as that of the second embodiment, and the similarities will not be repeated. The difference lies in the structure of the tensioning component.

[0125] refer to Figure 7 , in the present embodiment, the tightening assembly includes a tightening screw 3 and a nut 31, one end of the tightening screw 3 in the present embodiment is provided with a fixed cap end, and the other end is provided with an external thread; the nut 31 is provided with an internal thread, and The threaded end of tension screw rod 3 cooperates. During assembly, the tension screw 3 is installed on the chassis 1 and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com