Composite biological bacterial fertilizer for petroleum-contaminated soil and preparation method thereof

A technology of complex biological bacteria and oil pollution, applied in the field of fertilizers, can solve the problems of low nutrient absorption, slow crop growth, low economic efficiency, etc., and achieve the effects of promoting degradation, promoting dispersion, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

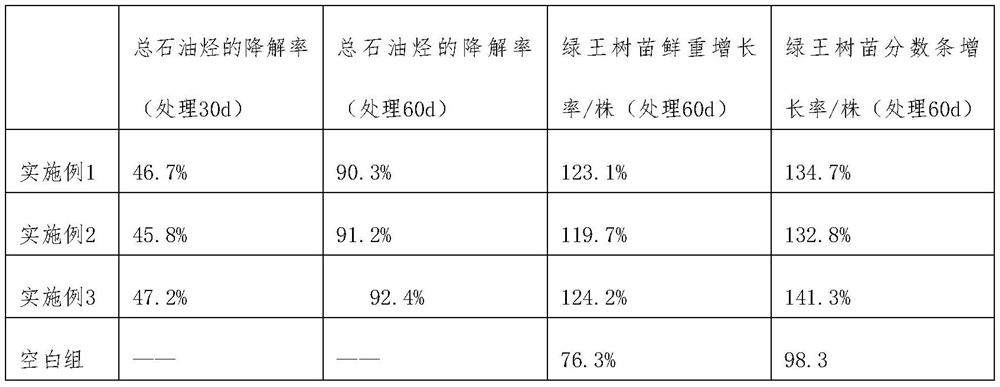

Examples

Embodiment 1

[0026] Embodiment 1 Composite biological bacterial fertilizer for oil-contaminated soil

[0027] 1. Preparation of modified composite carrier:

[0028] The modified composite carrier is made of soybean meal, rapeseed meal and nanoscale fly ash in a mass ratio of 5:5:2.

[0029] Preparation process: mixing soybean meal and rapeseed meal, after superfine grinding, adding 0.5% phytic acid by mass, standing for 20-25min, adding water to prepare a 40w% slurry; then adding 3% phytic acid by mass to the slurry Stearic acid and sodium hexametaphosphate with a mass of 0.1% are treated at 80-90° C. for 2 hours and dried to obtain a composite carrier.

[0030] 2. Immobilized bacterial agent

[0031] 2.1 Preparation of immobilized carrier:

[0032] The fixed carrier is made of inorganic nanoparticles, phosphite, and chitosan at a mass ratio of 0.5:2:10; wherein the inorganic nanoparticles are made of nano-Fe 3 o 4 , Nano-calcium borate is composed of 1:1 mass ratio.

[0033]Preparat...

Embodiment 2

[0041] Embodiment 2 Composite biological bacterial fertilizer for oil-contaminated soil

[0042] 1. Preparation of modified composite carrier:

[0043] The modified composite carrier is made of soybean meal, rapeseed meal and nanoscale fly ash at a mass ratio of 5:7:3.

[0044] Preparation process: mix soybean meal and rapeseed meal, after superfine grinding, add 0.8% phytic acid by mass, let it stand for 20-25 minutes, add water to prepare 45w% slurry; then add 4% phytic acid by mass to the slurry Stearic acid and sodium hexametaphosphate with a mass of 0.2% are treated at 80-90° C. for 2.5 hours, and dried to obtain a composite carrier.

[0045] 2. Immobilized bacterial agent

[0046] 2.1 Preparation of immobilized carrier:

[0047] The fixed carrier is made of inorganic nanoparticles, phosphite, and chitosan at a mass ratio of 0.8:2.5:12; wherein the inorganic nanoparticles are made of nano-Fe 3 o 4 , Nano-calcium borate is composed of 1:1 mass ratio.

[0048] Prepara...

Embodiment 3

[0056] Embodiment 3 Composite biological bacterial fertilizer for oil-contaminated soil

[0057] 1. Preparation of modified composite carrier:

[0058] The modified composite carrier is made of soybean meal, rapeseed meal and nanoscale fly ash in a mass ratio of 8:5:3.

[0059] Preparation process: mixing soybean meal and rapeseed meal, after superfine grinding, adding 1% phytic acid by mass, standing for 25 minutes, adding water to make a 50w% slurry; then adding 5% stearin by mass to the slurry The acid and its mass of 0.3% sodium hexametaphosphate are treated at 80-90° C. for 3 hours and dried to obtain a composite carrier.

[0060] 2. Immobilized bacterial agent

[0061] 2.1 Preparation of immobilized carrier:

[0062] The fixed carrier is made of inorganic nanoparticles, phosphite, and chitosan at a mass ratio of 1:2:10; wherein the inorganic nanoparticles are made of nano-Fe 3 o 4 , Nano-calcium borate is composed of 1:1 mass ratio.

[0063] Preparation process: Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com