Preparation method of high-impact transparent polypropylene resin

A technology of transparent polypropylene and high impact resistance, applied in the field of high-end new materials, can solve the problems of difficult operation, low impact strength at room temperature, poor transparency of ethylene-propylene block copolymers, etc., achieve high transparency, increase low temperature resistance and The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with drawings and embodiments.

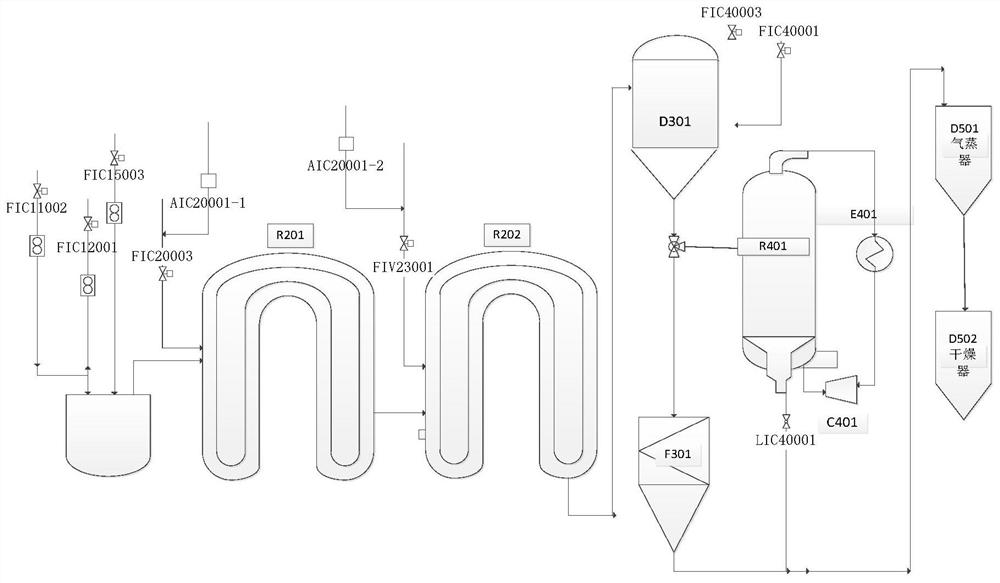

[0051] figure 1 A schematic diagram of the apparatus for preparing polypropylene resin is given.

[0052] in:

[0053] 1. To produce high-impact transparent polypropylene, the main catalyst uses Ziegler-Natta's fourth-generation ZN catalyst, the main component of which is TiCl 4 , Carrier MgCl 2 , The internal electron donor, the external electron donor is cyclohexylmethyldimethoxysilane (Donor-C), and the activator is triethylaluminum (TEAL). During production, external electron donor and triethylaluminum, loop reactor propylene and triethylaluminum are all controlled in a certain ratio range.

[0054] 2. As the chain transfer agent of polymerization reaction, hydrogen has the function of adjusting the molecular weight and controlling the melt index of the product. During production, the amount of hydrogen added is adjusted according to the target index. The amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com