Preparation process of non-soaking antibacterial and deodorant cotton

A preparation process, antibacterial cotton technology, applied in the direction of non-woven fabrics, rayon manufacturing, plant fibers, etc., can solve problems such as difficult large-scale and low-cost production practices, complex preparation processes, etc., to reduce peeling and improve antibacterial properties , Good washing resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

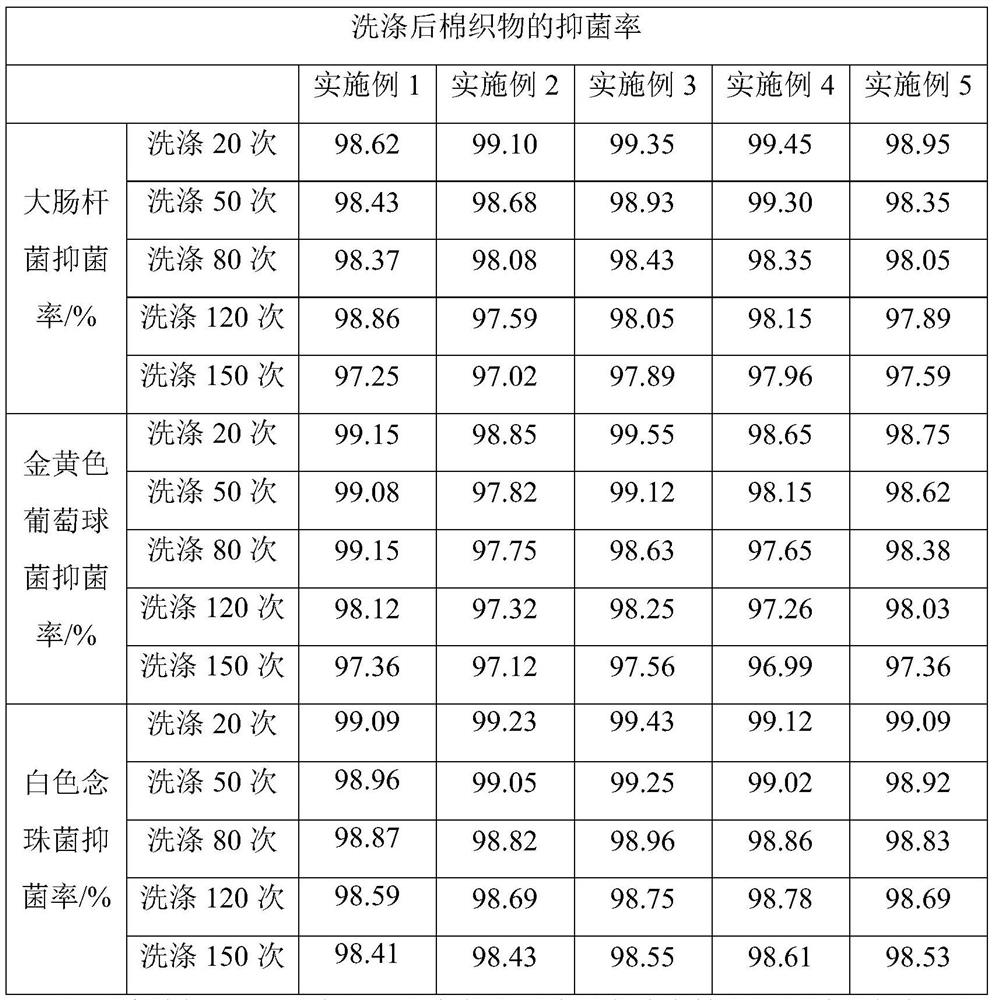

Examples

Embodiment 1

[0027] A kind of preparation technology of non-soaking antibacterial and deodorant cotton

[0028] Non-soaking antibacterial and deodorant cotton, prepared by the following steps:

[0029] Step (1): Pretreat the dried cotton fibers: soak them in a concentrated sodium hydroxide solution at 50°C for 30 minutes at room temperature, then wash them in hot water at 50°C for 3 times, and finally rinse them with cold water and dry them;

[0030] Step (2): carry out antibacterial treatment to the cotton fiber after step (1) pretreatment: the cotton fiber after step (1) pretreatment is in diethylenetriamine-ethanol solution, zinc nitrate hexahydrate solution and silver nitrate solution composition Soak in the mixed solution for 30 minutes, and keep stirring; then raise the temperature to 30°C, continue to stir, and add zinc nitrate solution dropwise while stirring; take out the cotton fiber from the solution and place it in a microwave oven, and heat it at a power of 600W for 10 minutes...

Embodiment 2

[0037] A kind of preparation technology of non-soaking antibacterial and deodorant cotton

[0038] Non-soaking antibacterial and deodorant cotton, prepared by the following steps:

[0039]Step (1): Pretreat the dried cotton fibers: soak them in a concentrated sodium hydroxide solution at 55°C for 25 minutes at room temperature, then wash them twice in hot water at 50-70°C, rinse them with cold water, and dry them;

[0040] Step (2): carry out antibacterial treatment to the cotton fiber after step (1) pretreatment: the cotton fiber after step (1) pretreatment is in diethylenetriamine-ethanol solution, zinc nitrate hexahydrate solution and silver nitrate solution composition Soak in the mixed solution for 30 minutes, and keep stirring; then raise the temperature to 35°C, continue to stir, and add the zinc nitrate solution dropwise while stirring; take out the cotton fiber from the solution and place it in a microwave oven, and heat it at a power of 600W for 5 minutes to obtain a...

Embodiment 3

[0047] A kind of preparation technology of non-soaking antibacterial and deodorant cotton

[0048] Non-soaking antibacterial and deodorant cotton, prepared by the following steps:

[0049] Step (1): Pretreat the dried cotton fibers: soak them in a concentrated sodium hydroxide solution at 50-60°C for 25 minutes at room temperature, then wash them in hot water at 55°C for 3 times, and finally rinse them with cold water and dry them;

[0050] Step (2): carry out antibacterial treatment to the cotton fiber after step (1) pretreatment: the cotton fiber after step (1) pretreatment is in diethylenetriamine-ethanol solution, zinc nitrate hexahydrate solution and silver nitrate solution composition soak in the mixed solution for 30 minutes, and keep stirring; then raise the temperature to 32°C, continue to stir, and add the zinc nitrate solution dropwise while stirring; take out the cotton fiber from the solution and place it in a microwave oven, and heat it for 6 minutes at a power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com