Active lime calcining system

A technology of activated lime and calcination, applied in the field of lime calcination, can solve the problems such as difficult to effectively use low calorific value gas, achieve the effects of avoiding environmental pollution and waste of thermal energy resources, improving utilization rate, and reducing calcination energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

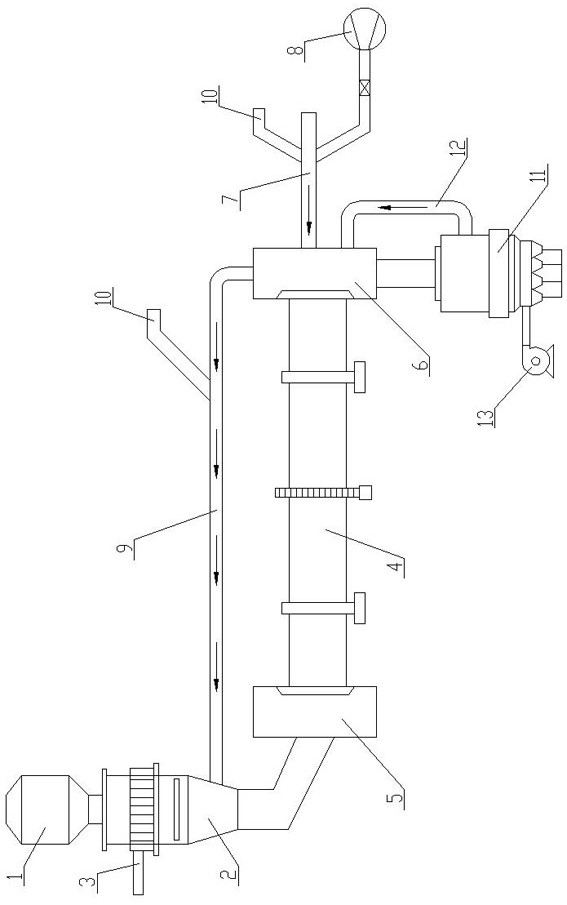

[0018] Referring to the accompanying drawings, the specific implementation is as follows:

[0019] An active lime calcination system, comprising a silo 1, a rotary kiln 4 and a cooling device 11 for cooling materials calcined in the rotary kiln 4, the outlet of the silo 1 is connected to a preheater 2, and the preheater 2 The feed channel is connected with the kiln tail box 5 of the rotary kiln 4, so that the material can be calcined in the rotary kiln 4 after being preheated. The preheater 2 is connected with a waste gas pipe 3 for the preheated waste gas to flow out.

[0020] The kiln head box 6 of the rotary kiln 4 is connected to the first burner 7, and the air inlet of the first burner 7 is connected to the combustion-supporting air supply device 8. The combustion-supporting air supply device 8 can be a combustion-supporting fan or an oxygen station. The device 7 is also connected with a fuel pipe 10 for the inflow of low calorific value gas with a calorific value less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com