Solar cell and front electrode thereof, and preparation methods and applications thereof

A technology for solar cells and front electrodes, applied in the field of solar cells, can solve problems such as poor collection effect, achieve the effects of reducing metallization recombination, satisfying welding quality, and ensuring the collection effect of front electrodes on carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The preparation method of the solar cell of the present embodiment comprises the following steps:

[0073] 1. Texture making: Use single crystal P-type silicon wafers (158 specifications), and use alkali to make texturing on the front and back to form a textured structure.

[0074] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature to make the front diffuse to form a PN emitter junction. After diffusion, the square resistance of the thin layer on the front surface is 160Ω / □.

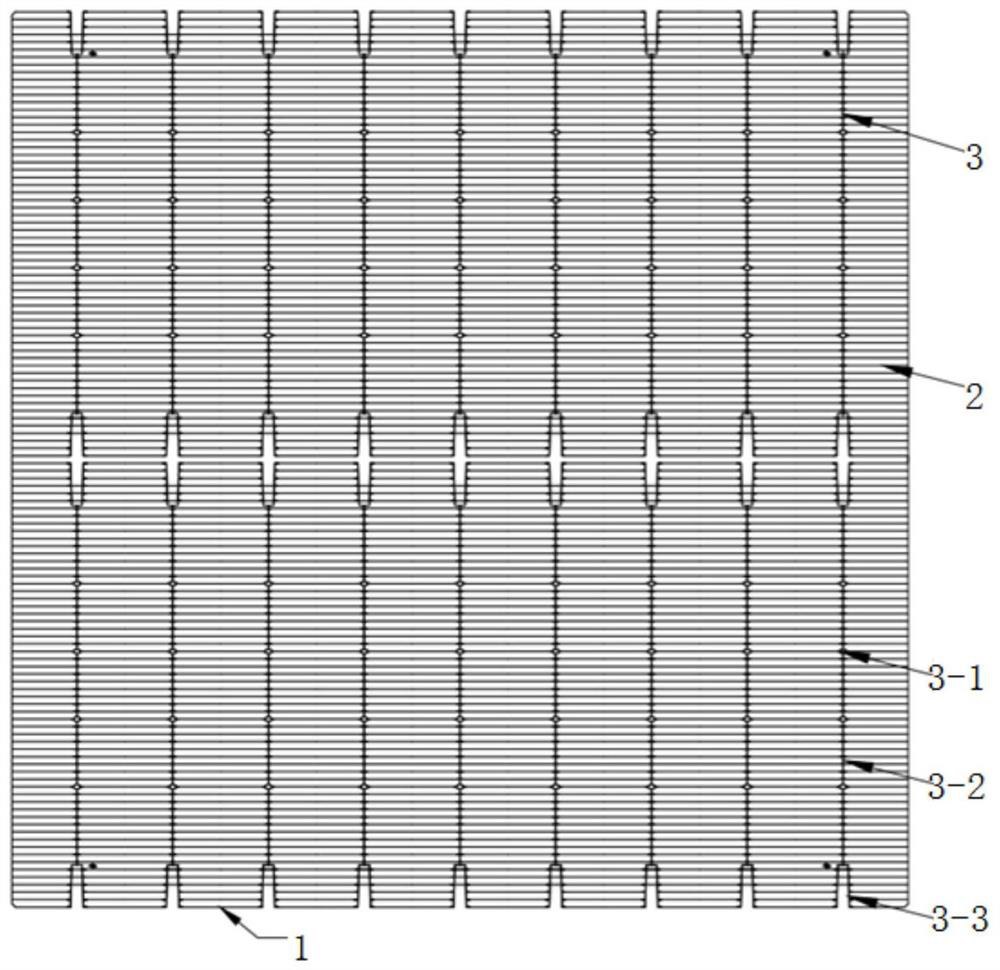

[0075] 3. Laser SE: Using diffused phosphosilicate glass as a phosphorus source, laser doping is carried out on the front side of the diffused silicon wafer and the metallized area corresponding to the positive electrode grid line to form a heavily doped area and a square in the heavily doped area The resistance is between 70Ω / □. The laser SE pattern adopts the pattern without main grid ( figure 2 ).

[0076] 4. Thermal o...

Embodiment 2

[0092] The preparation method of the PERC solar cell of the present embodiment comprises the following steps:

[0093] 1. Texture making: Use single crystal P-type silicon wafers (166 specifications), use alkali to make texturing on the front and back to form a textured structure.

[0094] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature, so that the front diffuses to form a PN emitter junction. The sheet resistance of the thin layer on the front surface after diffusion was 150Ω / □.

[0095] 3. Laser SE: Using the diffused phosphosilicate glass as the phosphorus source, laser doping is performed on the front side of the diffused silicon wafer and the metallized area corresponding to the positive electrode grid line to form a heavily doped area. The sheet resistance of the heavily doped region is between 60Ω / □. The laser SE pattern adopts the pattern without main grid ( figure 2 ).

[0096] 4. Therma...

Embodiment 3

[0111] The preparation method of the PERC solar cell of the present embodiment comprises the following steps:

[0112] 1. Texture making: Use single crystal P-type silicon wafers (166 specifications), use alkali to make texturing on the front and back to form a textured structure.

[0113] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature, so that the front diffuses to form a PN emitter junction. The sheet resistance of the thin layer on the front surface after diffusion was 120Ω / □.

[0114] 3. Laser SE: Using the diffused phosphosilicate glass as the phosphorus source, laser doping is performed on the front side of the diffused silicon wafer and the metallized area corresponding to the positive electrode grid line to form a heavily doped area. The sheet resistance of the heavily doped region is between 60Ω / □. The laser SE pattern adopts the pattern without main grid ( figure 2 ).

[0115] 4. Therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com