Functional filler and anti-seismic energy-absorbing material for seismic resistance and energy absorption and preparation methods thereof

A technology of functional fillers and energy-absorbing materials, applied in the field of protective materials, can solve problems such as limited impact resistance, and achieve the effects of improving the degree of cross-linking, superior energy absorption and impact resistance, and improving energy absorption effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

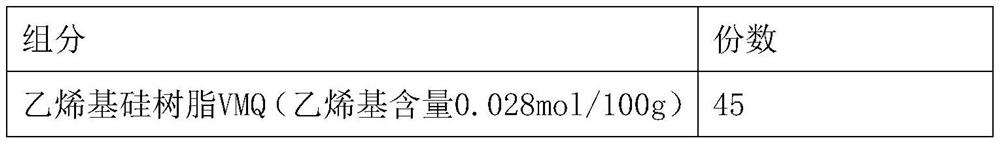

preparation example Construction

[0030]The preparation method of the anti-shock energy-absorbing material of the invention is simple in operation and easy in industrialized production. At the same time, in the preparation method of the anti-seismic energy-absorbing material, a high-molecular polymer is used as a matrix, supplemented by a polyborosiloxane-acrylate spherical shell with a three-dimensional structure as a functional filler, and an efficient anti-seismic energy-absorbing material is finally prepared. . Polyborosiloxane elastomer is a strain rate responsive smart material. The hardness, modulus and rigidity of the material will change with external force. When impacted by external force, polyborosiloxane is flexible due to rapid extrusion. The distance between the boron and oxygen atoms on the chain segment is reduced to form a coordination bond, which increases the degree of crosslinking, and the material becomes more elastic. When the external force disappears, it recovers, thereby playing an ene...

Embodiment 1

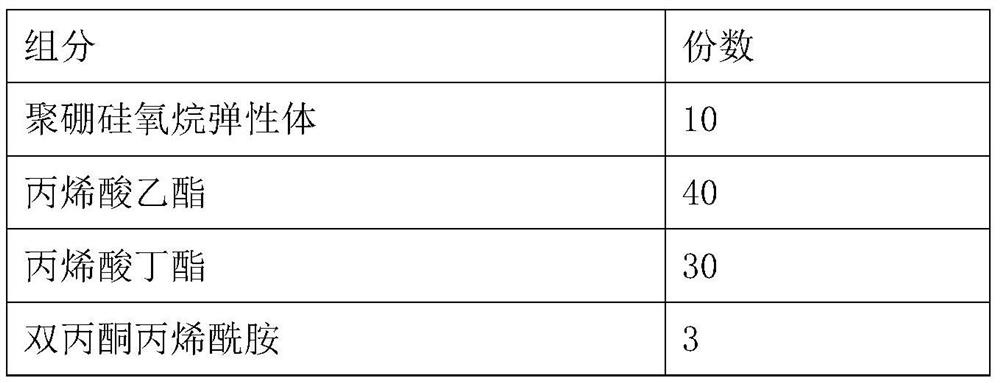

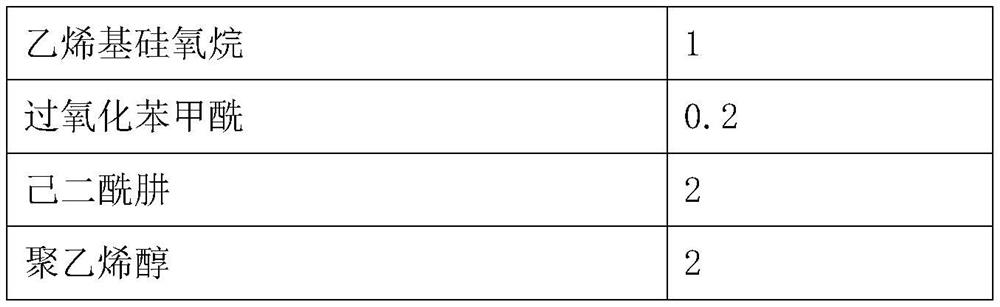

[0033] 1. Preparation of polyborosiloxane-acrylate polymer as functional spherical shell filler

[0034] components g Polyborosiloxane Elastomer 30 ethyl acrylate 40 Butyl acrylate 30 diacetone acrylamide 3 Vinyl siloxane 1 Benzoyl peroxide 0.2 Adipic hydrazide 2 Sodium dodecyl benzene sulfonate 3

[0035] Polyborosiloxane elastomer is dissolved in 100g ethyl acetate to form polyborosiloxane elastomer solution, ethyl acrylate, butyl acrylate, diacetone acrylamide, vinyl siloxane monomer and initiator Benzoyl oxide is dissolved in 50g of ethyl acetate to form a monomer mixture, and the emulsifier sodium dodecylbenzenesulfonate is mixed with 200g of water to form an aqueous phase, and the polyborosiloxane elastomer solution, 20 % of the monomer mixture and the water phase are mixed under high-speed stirring to initiate seed emulsion polymerization, wherein the polyborosiloxane exists in the form of seeds in the water ...

Embodiment 2

[0040] 1. Preparation of polyborosiloxane-acrylate polymer as functional spherical shell filler

[0041] components number of copies Polyborosiloxane Elastomer 30 ethyl acrylate 40 Butyl acrylate 30 Glycidyl methacrylate 3 Vinyl siloxane 1 Benzoyl peroxide 0.2 Ethylenediamine 2 Sodium dodecyl benzene sulfonate 5

[0042] Polyborosiloxane elastomer is dissolved in 100g ethyl acetate to form polyborosiloxane elastomer solution, ethyl acrylate, butyl acrylate, glycidyl methacrylate, vinyl siloxane monomer and initiator The agent benzoyl peroxide was dissolved in 50g of ethyl acetate to form a monomer mixture, and the emulsifier sodium dodecylbenzenesulfonate was mixed with 200g of water to form an aqueous phase, and the polyborosiloxane elastomer solution , 20% monomer mixture and the water phase are mixed under high-speed stirring to initiate seed emulsion polymerization, wherein polyborosiloxane exists in the form o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com