Neutral transparent silicone adhesive and preparation method thereof

A silicone adhesive, transparent technology, applied in chemical instruments and methods, adhesives, silicon compounds, etc., can solve the problems of difficulty in dispersion, rising costs, reducing the production cost of transparent silicone adhesives, etc. polar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of neutral transparent silicone glue comprises following preparation steps:

[0054] Vacuumize the base rubber, silicone oil, and precipitated white carbon black at 100°C-150°C for 2h-4h, and then ventilate and cool to obtain the base rubber mixture; the cooled base rubber mixture, crosslinking agent, coupling agent, Mix the plasticizer, vacuumize and stir for 30min-40min, and then put it in a cylinder to obtain a neutral transparent silicone glue.

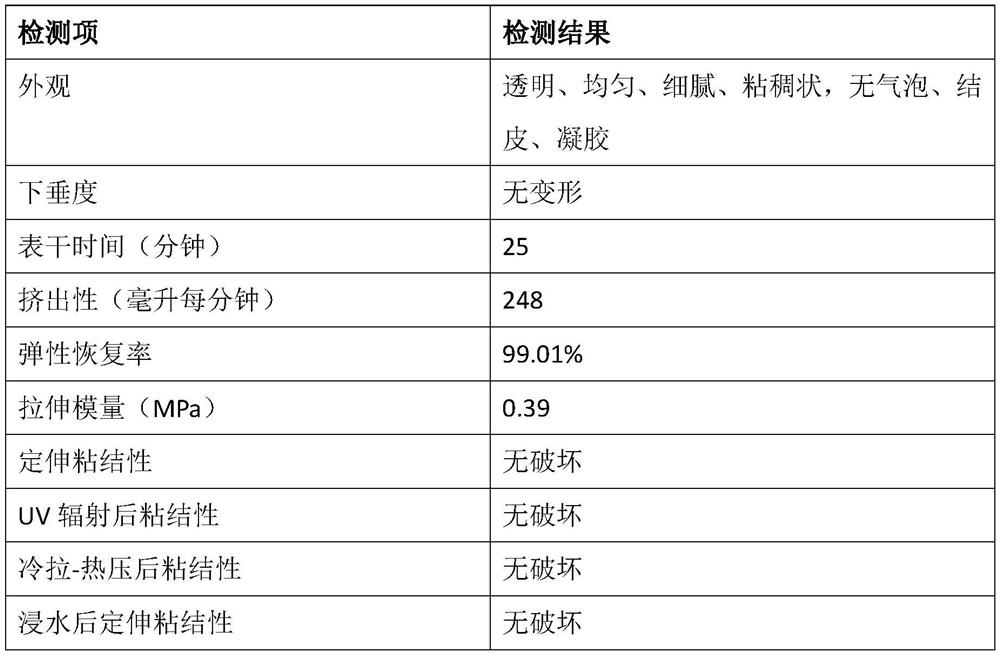

Embodiment 1

[0057] Put 1500g of 107 glue with a viscosity of 80,000, 1647g of silicone oil, and 500g of precipitated white carbon black at 150°C for 3 hours in a vacuum (the pressure is lower than 0.08MPa), and then ventilate and cool to prepare the base glue; weigh 1000g of the base glue, methyl Tributylketoxime base silane 67.2g, vinyl tributylketoxime base silane 8g, KH-550 silane coupling agent 2.4g, KH-560 silane coupling agent 5.6g, white oil 80g, vacuumize and stir for 30 minutes (pressure lower than 0.08MPa), and then put it in a cylinder to obtain a neutral transparent silicone glue.

[0058] Wherein, the precipitated silica comprises the following preparation steps:

[0059] At a temperature of 80°C, inject 100L of bottom water and 75L of 20wt% water glass solution into the stirred reaction vessel, and add sulfuric acid with a concentration of 10wt% until the pH value of the system becomes 6, and the addition time is 30 minutes. After the reaction was completed, the temperature...

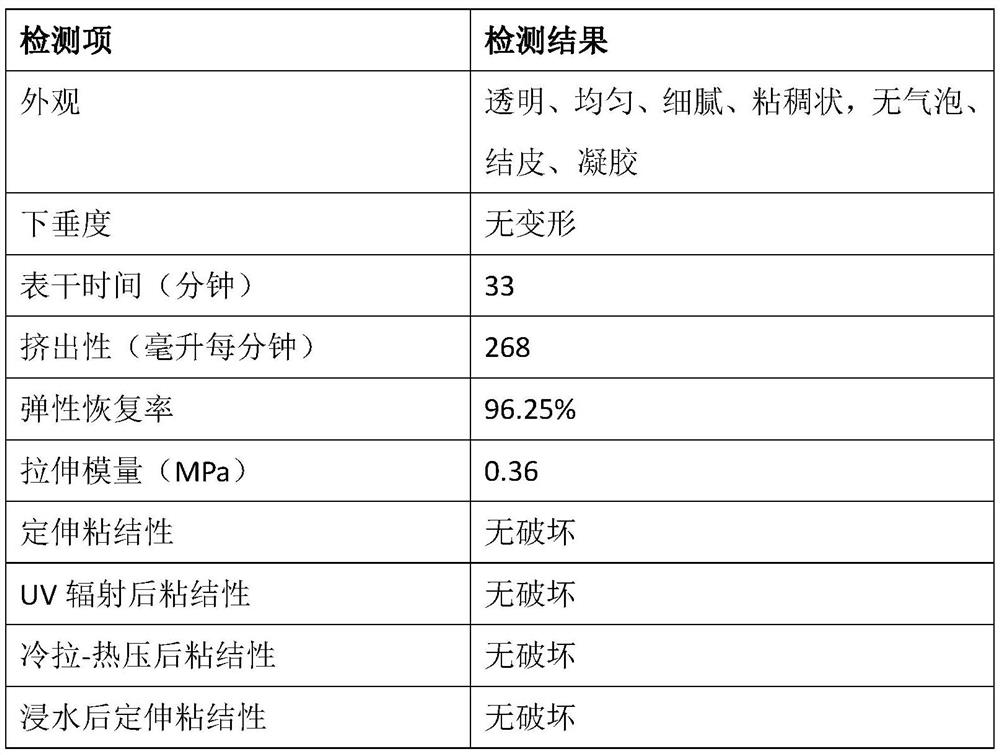

Embodiment 2

[0064] Put 1500g of 107 glue with a viscosity of 80,000, 1647g of silicone oil, and 500g of precipitated white carbon black at 150°C for 3 hours in a vacuum (the pressure is lower than 0.08MPa), and then ventilate and cool to prepare the base glue; weigh 1000g of the base glue, methyl Tributylketoxime base silane 67.2g, vinyl tributylketoxime base silane 8g, KH-550 silane coupling agent 2.4g, KH-560 silane coupling agent 5.6g, white oil 80g, vacuumize and stir for 30 minutes (pressure lower than 0.08MPa), and then put it in a cylinder to obtain a neutral transparent silicone glue.

[0065] Wherein, the precipitated silica comprises the following preparation steps:

[0066] At a temperature of 60°C, inject 100L of bottom water and 75L of 20wt% water glass solution into the stirred reaction vessel, and add sulfuric acid with a concentration of 30wt% until the pH value of the system becomes 5, and the addition time is 30 minutes. After the reaction was completed, the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com