Preparation method of nano-copper modified alloy tableware

A technology for nano-copper and tableware, applied in the field of nano-copper, can solve the problems of hot surface, easy breakage of tableware, easy residual oil and water, etc., and achieve the effects of reducing adhesion, reducing metal thermal conductivity, and reducing heat conduction efficiency and speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

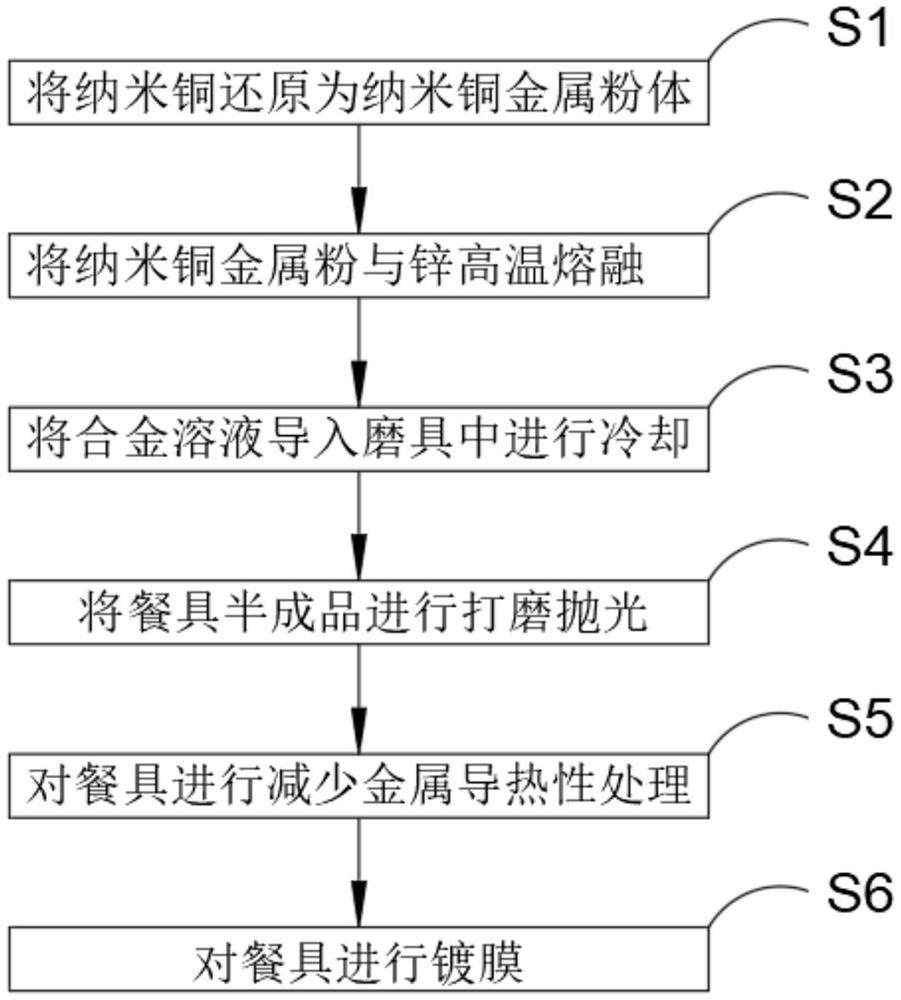

[0032] A method for preparing nanometer copper modified alloy tableware, when a kind of nanometer copper modified alloy tableware is a bowl, comprises the following steps:

[0033] Step 1. The nano-copper is modified and reduced by a chemical reduction method to reduce and grow into a nano-copper metal powder.

[0034] Step 2, putting nanometer copper metal powder and zinc oxide into a crucible for high-temperature melting to obtain an alloy solution.

[0035] Step 3. Pour the high-temperature molten alloy solution into the bowl mold for cooling and forming.

[0036] Step 4. Take out the semi-finished product from the bowl mold, heat the semi-finished product again, keep it warm, take out the semi-finished product after cooling down, and polish it according to the requirements of the bowl.

[0037] Step 5, the polished bowl is treated to reduce metal thermal conductivity.

[0038] Step 6. Spray Teflon microporous film on the surface of the bowl to enhance the hydrophobicity ...

Embodiment 2

[0055] A method for preparing nanometer copper modified alloy tableware, when a kind of nanometer copper modified alloy tableware is a bowl, comprises the following steps:

[0056] Step 1. The nano-copper is modified and reduced by a chemical reduction method to reduce and grow into a nano-copper metal powder.

[0057] Step 2, putting nanometer copper metal powder and zinc oxide into a crucible for high-temperature melting to obtain an alloy solution.

[0058] Step 3. Pour the alloy solution melted at high temperature into the dish mold for cooling and forming.

[0059] Step 4. Take out the semi-finished product from the dish mold, heat the semi-finished product again, keep it warm, take out the semi-finished product after cooling down, and polish it according to the needs of the dish.

[0060] Step 5, performing treatment on the polished disc to reduce metal thermal conductivity.

[0061] Step 6. Spray Teflon microporous film on the surface of the disc to enhance the hydrop...

Embodiment 3

[0078] A method for preparing nanometer copper modified alloy tableware, when a kind of nanometer copper modified alloy tableware is a bowl, comprises the following steps:

[0079] Step 1. The nano-copper is modified and reduced by a chemical reduction method to reduce and grow into a nano-copper metal powder.

[0080] Step 2, putting nanometer copper metal powder and zinc oxide into a crucible for high-temperature melting to obtain an alloy solution.

[0081] Step 3. Pour the alloy solution melted at high temperature into the tray mold for cooling and forming.

[0082] Step 4. Take out the semi-finished product from the disk mold, heat the semi-finished product again, keep it warm, take out the semi-finished product after cooling down, and polish according to the requirements of the disk.

[0083] Step 5, performing treatment on the polished disk to reduce the thermal conductivity of the metal.

[0084] Step 6. Spray Teflon microporous film on the surface of the disc to enh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com