Positive electrode material, modification method thereof and battery

A positive electrode material and modification technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of unstable high and low performance, poor cycle stability, and low Coulombic efficiency, and achieve good electrochemical comprehensive performance, Effects of low cost, improved cycle stability and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

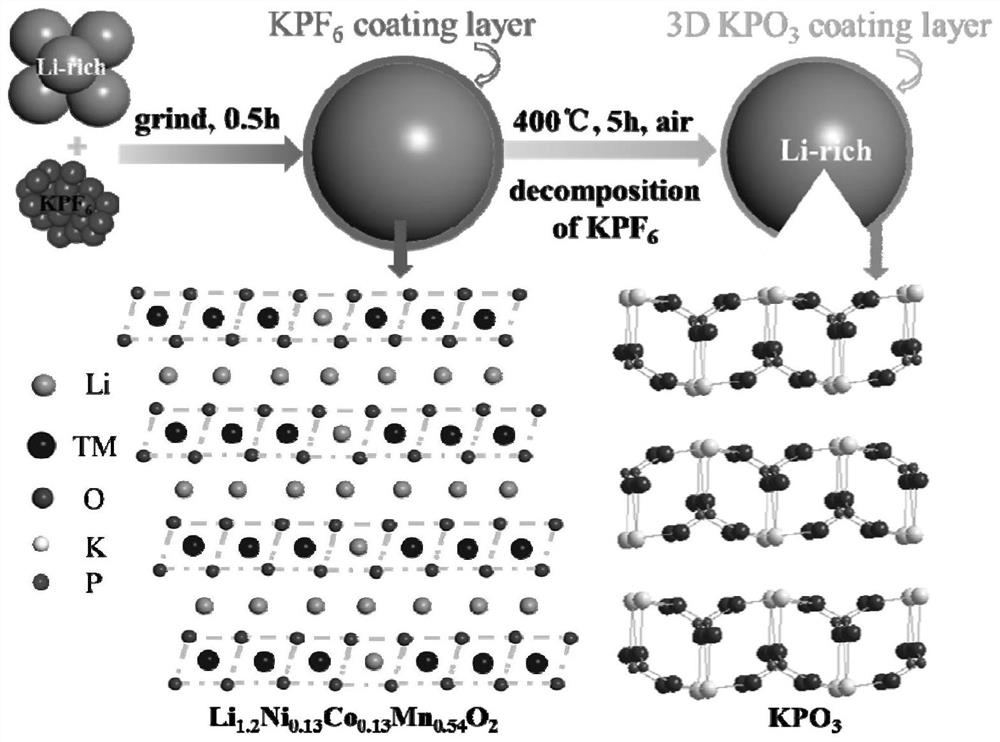

[0061] Embodiment 1. Potassium hexafluorophosphate modified 0.5Li 2 MnO 3 0.5LiNi 0.33 co 0.33 mn 0.33 o 2 (LNCM111)

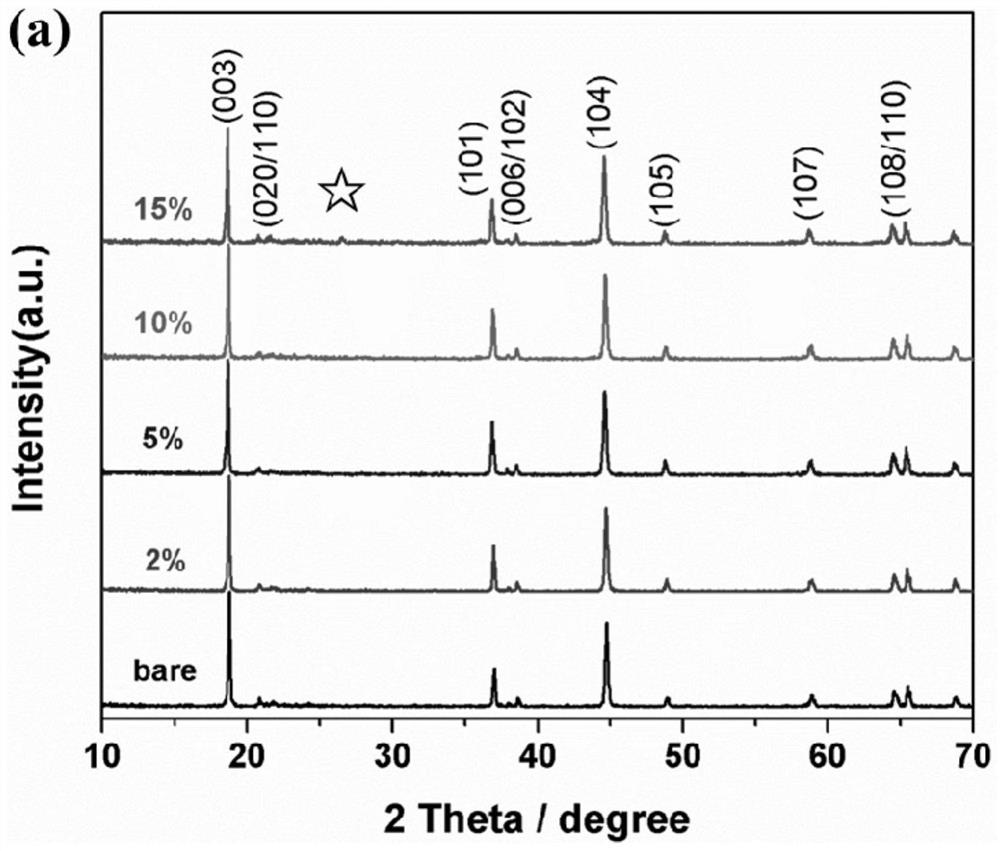

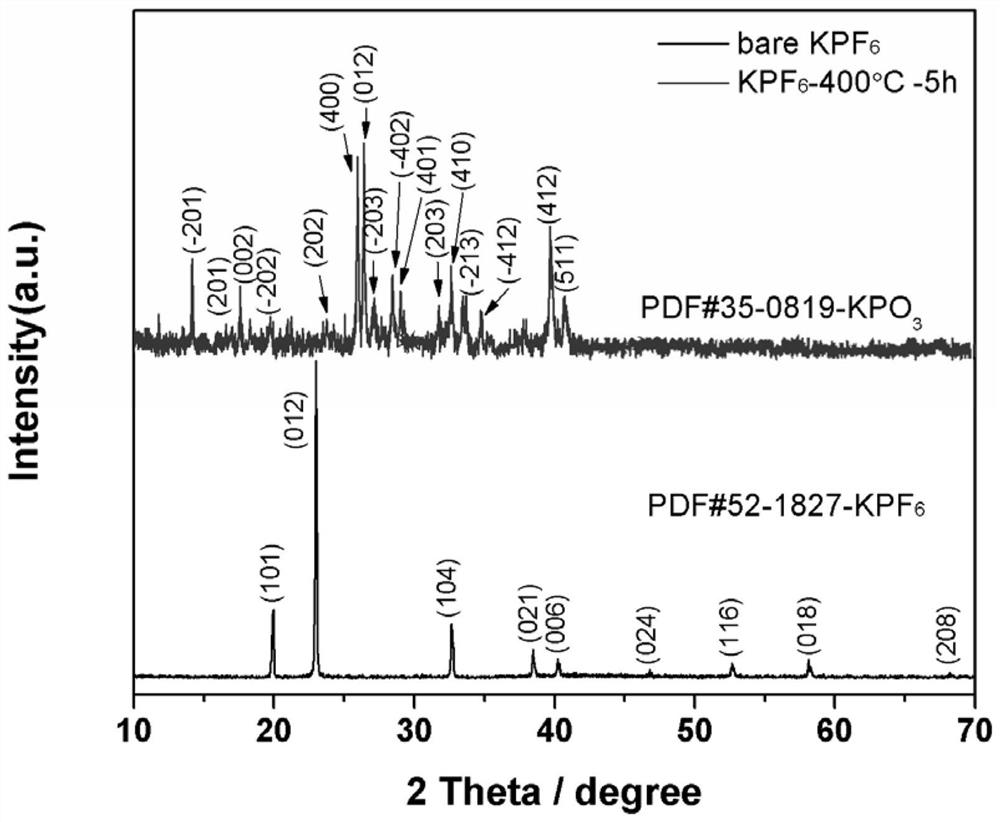

[0062] 0.02g, 0.05g, 0.1g, 0.15g KPF 6 The powder was dissolved in 2ml of absolute ethanol, ultrasonically dispersed for 5 minutes, added dropwise to 1g of LNCM111, ground together for 30 minutes to dryness, placed in a muffle furnace, calcined for 5 hours at 400°C in an air atmosphere, and the heating rate was 3°C / min to obtain With 2wt%, 5wt%, 10wt%, 15wt% KPF 6 Modified LNCM111.

Embodiment 2

[0063] Embodiment 2. Potassium hexafluorophosphate modified 0.5Li 2 MnO 3 0.5LiMn 0.5 Ni 0.2 co 0.3 o 2 (LNCM523)

[0064] 0.02g, 0.05g, 0.1g KPF 6 The powder was dissolved in 2ml of absolute ethanol, ultrasonically dispersed for 5min, added dropwise to 1gLNCM523, ground together for 30min until dry, placed in a muffle furnace, calcined at 400°C for 5h in an air atmosphere, and the heating rate was 3°C / min to obtain 2wt %,5wt%,10wt%KPF 6 Modified LNCM523.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com