Preparation method of solid electrolyte

A solid electrolyte and material technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve problems that affect battery energy density and low ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the solid electrolyte provided by the embodiment of the present application includes: dispersing the lithium precursor and the central atom ligand in an organic solvent to form a reaction initial mixture; dispersing the borate ester in an organic solvent to form a modified solution; The initial reaction mixture is mixed with the modified solution, and dried to obtain an initial product; the initial product is ground, cold-pressed, and heat-treated to obtain a solid electrolyte.

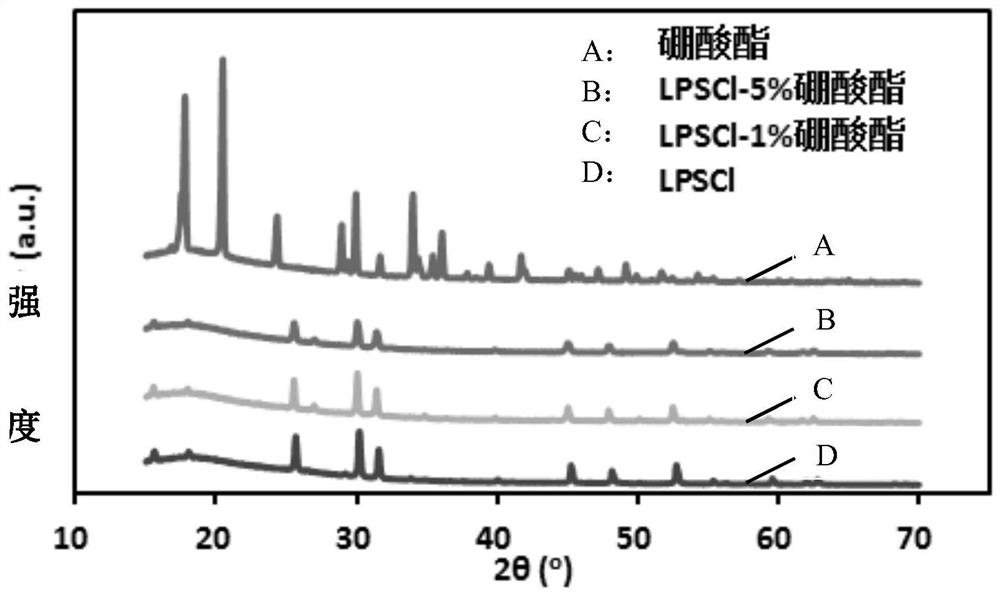

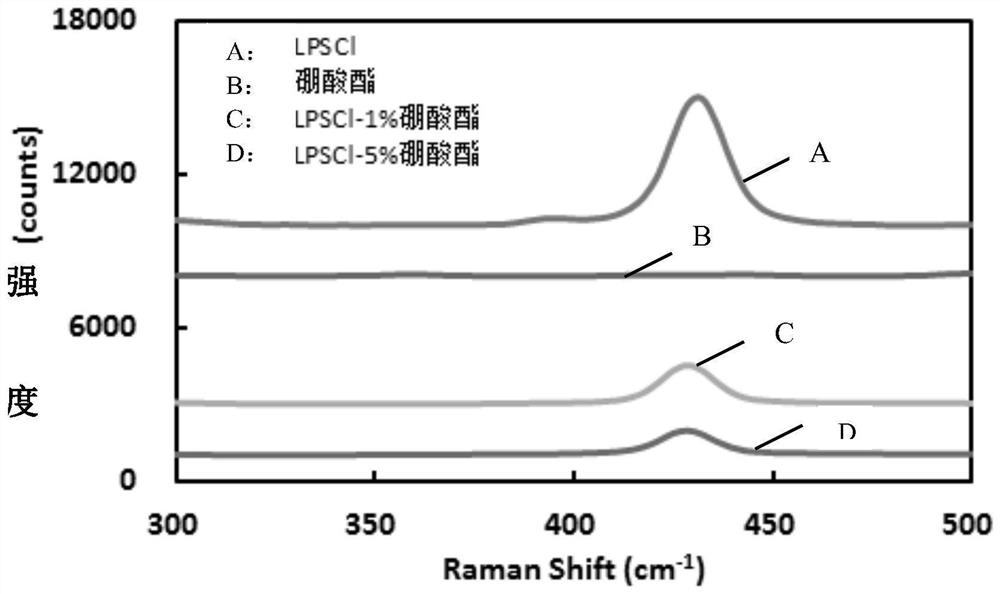

[0015] According to the embodiment of the present application, a B and O co-doped solid electrolyte can be obtained, wherein, B element doping can reduce the binding effect of anion on lithium ions, and improve the transport capacity of lithium ions; O element doping partially replaces S Elements can not only produce mixed anion effects to improve the conductivity of lithium ions, but also inhibit the formation of a space charge layer at the interface between the oxide ...

Embodiment 1

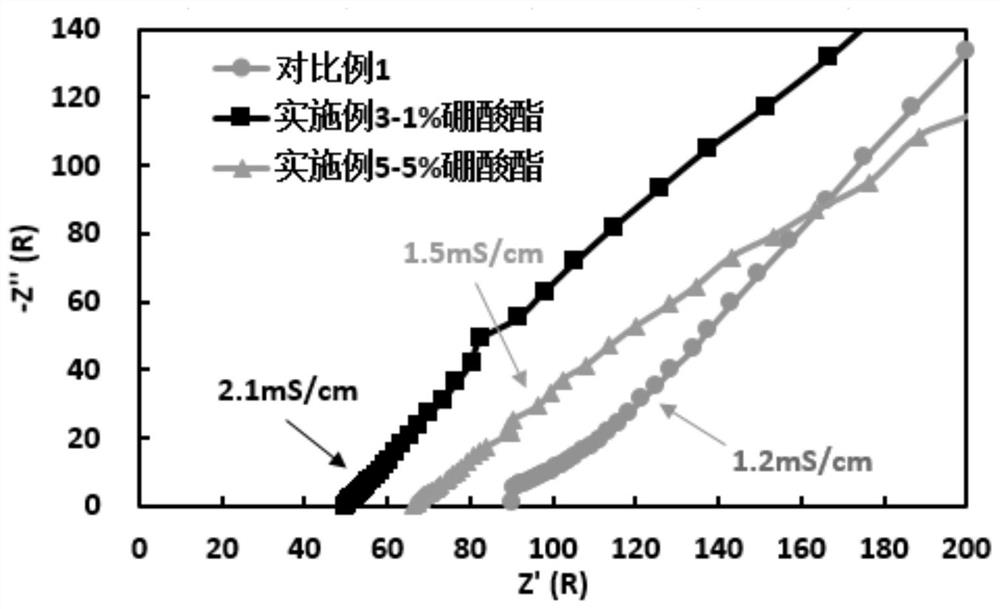

[0072] The data of Examples 1-5 and Comparative Example 1 show the influence of the amount of borate added on the performance of solid electrolyte and battery. Doping and modifying the sulfide solid-state electrolyte by adding boric acid ester (such as Examples 2, 3, and 4) in an appropriate amount can effectively improve the ionic conductivity and battery capacity of the solid-state electrolyte. But, when the addition of borate is too low (as in Example 1), although the conductivity of the solid electrolyte increases, the magnitude of the increase is small; and when the addition of borate is too high (as in Example 5 ), it will cause the concentration of lithium ions in the raw material to decrease, and the crystal structure of the electrolyte may also be affected, resulting in no further increase in conductivity. Thus considering the dual factors of cost and performance, in the embodiments of the present application, the addition amount of borate is in the following range: t...

Embodiment 7

[0074]Example 7 and Examples 10-13 show that in the steps of grinding, cold-pressing, and heat-treating the initial product to obtain a solid electrolyte, the cold-pressing pressure of the initial product can affect the performance of the solid electrolyte and battery. Specifically, the pressure of the cold pressing of the initial product will affect the diffusion process between elements during the high temperature heat treatment process. Structural formation and electrical conductivity promotion, although compared with comparative example conductivity to some extent, the magnitude of promotion is not large; and when the pressure is too large (as in Example 13), the block is easy to form severe cracking and is also unfavorable for product formation, Although the conductivity was increased compared to the comparative example, the performance improvement effect of Example 12 could not be achieved. Therefore, in the embodiments of the present application, the cold pressing step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com