Processing method of walnut kernel beverage

A processing method and technology of walnut kernels, applied in milk substitutes, dairy products, food science, etc., can solve the problems of high cost, increase enzyme inactivation steps, etc., and achieve the effects of long shelf life, uniform texture, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

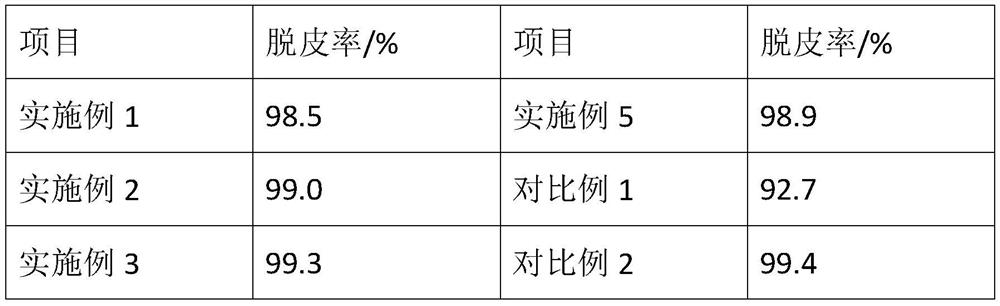

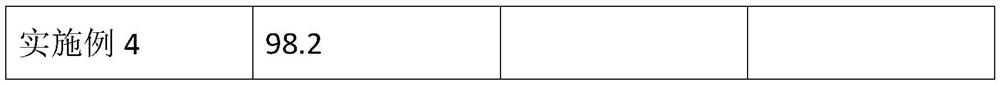

Examples

Embodiment 1

[0032] A processing method for walnut kernel beverage, comprising the steps of:

[0033] 1) Peeling: freeze the walnuts at -10°C for 30 minutes, then put the walnuts into the plasma activation machine under the conditions of pressure 50Pa, activation power 110W, and gas flow rate 0.5L / min , after being treated with plasma gas for 4 minutes, using 10°C deionized water to wash the walnut kernels under high pressure for 10 seconds under the condition that the flushing water pressure is 4 MPa, to obtain peeled walnut kernels;

[0034] 2) Preparation of the compounding solution: dissolving carrageenan and trehalose in distilled water at 70°C, stirring on a magnetic stirrer until completely dissolved, and then adjusting the pH to 7.0 to obtain the compounding solution;

[0035] 3) Preparation of spinach juice: Weigh the spinach, wash it, and then extract it at 65°C for 20 minutes according to the ratio of solid to liquid: 1:10;

[0036] 4) beating and blending: walnut kernels and s...

Embodiment 2

[0042] A processing method for walnut kernel beverage, comprising the steps of:

[0043] 1) Peeling: freeze the walnuts at -20°C for 40 minutes, then put the walnuts into the plasma activation machine under the conditions of pressure 60Pa, activation power 140W, and gas flow rate 1.0L / min , after being treated with plasma gas for 6 minutes, using 30°C deionized water to wash the walnut kernels under high pressure for 20 seconds under the condition that the flushing water pressure is 5 MPa, to obtain peeled walnut kernels;

[0044] 2) Preparation of the compounding solution: dissolving carrageenan and trehalose in distilled water at 70°C, stirring on a magnetic stirrer until completely dissolved, and then adjusting the pH to 7.5 to obtain the compounding solution;

[0045] 3) Preparation of spinach juice: after weighing the spinach, wash it, and then extract it at 80°C for 30 minutes according to the ratio of solid to liquid: 1:15;

[0046] 4) beating and blending: walnut kern...

Embodiment 3

[0052] A processing method for walnut kernel beverage, comprising the steps of:

[0053] 1) Peeling: freeze the walnuts at -15°C for 35 minutes, then put the walnuts into the plasma activation machine, under the conditions of pressure 55Pa, activation power 120W, and gas flow rate 0.8L / min , after being treated with plasma gas for 5 minutes, the walnut kernels were washed under high pressure for 15 seconds with deionized water at 20° C. under the condition that the flushing water pressure was 4.5 MPa, to obtain peeled walnut kernels;

[0054] 2) Preparation of the compounding solution: dissolving carrageenan and trehalose in distilled water at 70°C, stirring on a magnetic stirrer until completely dissolved, and then adjusting the pH to 7.2 to obtain the compounding solution;

[0055] 3) Preparation of spinach juice: Weigh the spinach, wash it, and then extract it at 70°C for 25 minutes according to the ratio of solid to liquid of 1:12;

[0056] 4) beating and blending: walnut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com