SiC-based composite material with high-temperature ceramic coating YSZ-RETaO4 and preparation method of SiC-based composite material

A technology of high-temperature ceramics and composite materials, applied in the field of composite materials, can solve the problems of being corroded by the environment and restricting the development of silicon carbide in the field of aero-engines, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

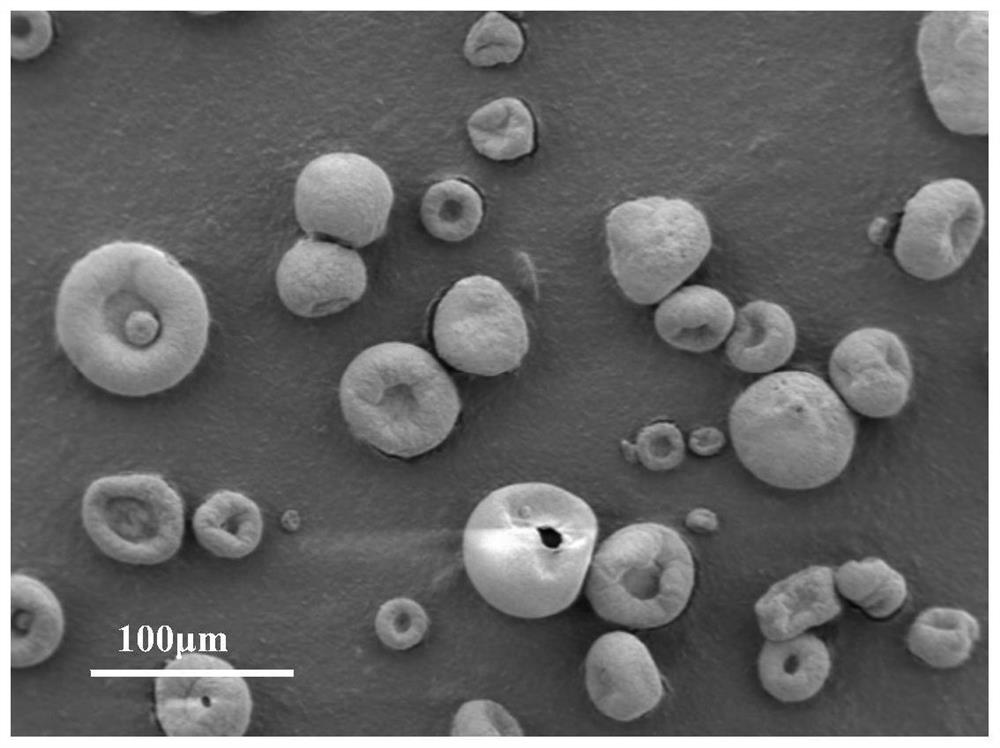

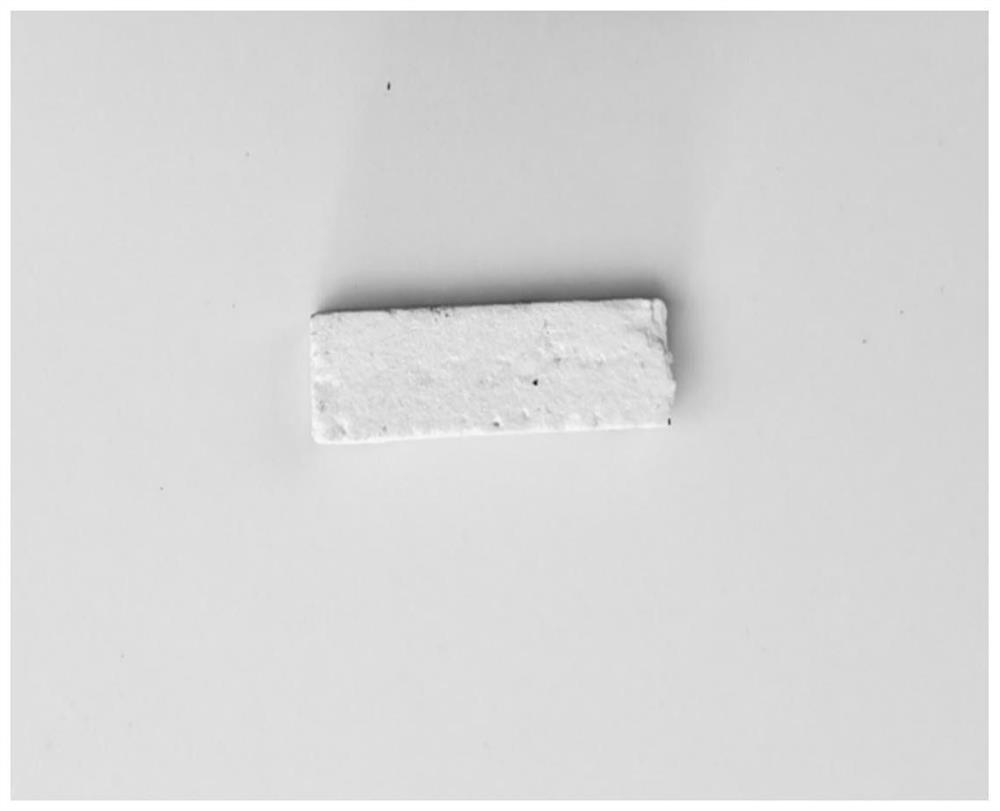

[0034] With high temperature ceramic coating YSZ-RETaO 4 The SiC-based composite material, including the SiC matrix, is equipped with a transition layer and a ceramic coating outside the SiC matrix, where the composition of the transition layer includes alumina, aluminum hydroxide, aluminum dihydrogen phosphate and aluminosilicate, and the ceramic coating The composition is YSZ (3 / 6) -(YTaO4) (3 / 6) .

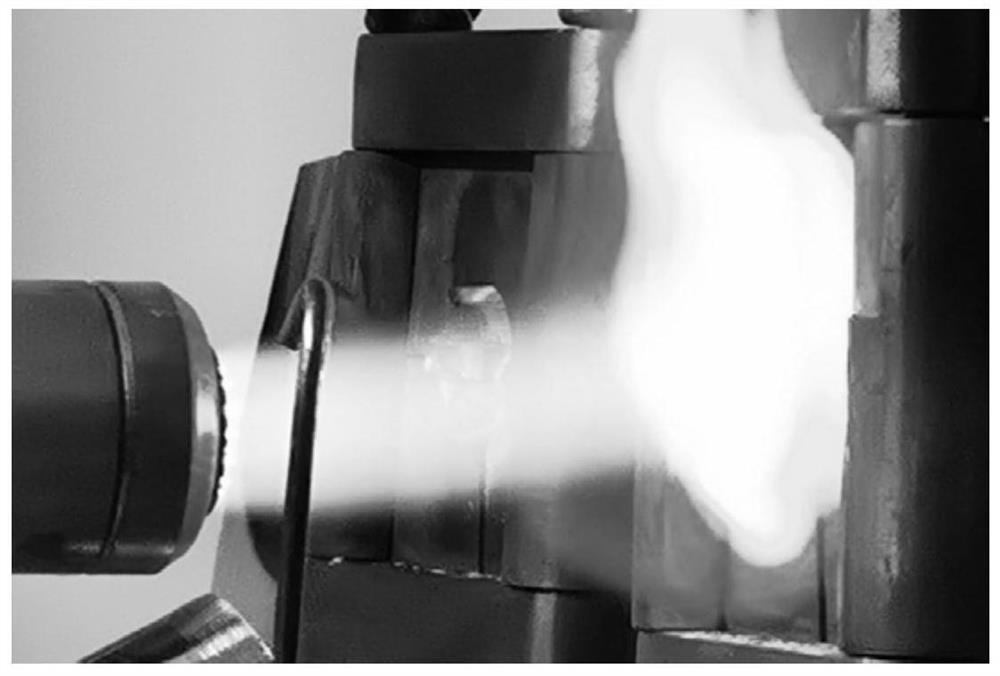

[0035] The concrete preparation method of above-mentioned material comprises the following steps:

[0036] Step 1: Take by weighing 58g aluminum oxide, 158g aluminum hydroxide, 155g aluminum dihydrogen phosphate and 62g calcium oxide, and place them together with absolute ethanol in a ball mill jar to seal and carry out ball milling. The rotating speed of the ball mill is 400r / min, and the ball milling time is After 300 minutes, the various powders were mixed evenly, and then dried at 80°C for 48 hours, and passed through a 300-mesh sieve for later use.

[0037] Step 2: Embed ...

Embodiment 2~7、 comparative example 1~4

[0043] The difference from Example 1 is that the process parameters in the preparation process are different, as shown in Table 1 for details.

[0044] Table 1 is the preparation process parameter table of embodiment 2~7 and comparative example 1~4

[0045]

Embodiment 8

[0047] The difference from Example 1 is that the ceramic coating in this example is YSZ (3 / 6) -(GdTaO4) (3 / 6) , where GdTaO 4 The preparation method of the powder is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com