Preparation method of cast nylon 6 polydimethylsiloxane copolymer

A technology of ester-based polydimethylsiloxane and dimethylsiloxane, which is applied in the field of preparation of cast nylon 6 polydimethylsiloxane copolymer, which can solve the loss of modifier loss and uneven material and other problems, to achieve the effect of reducing water absorption, good modification effect, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

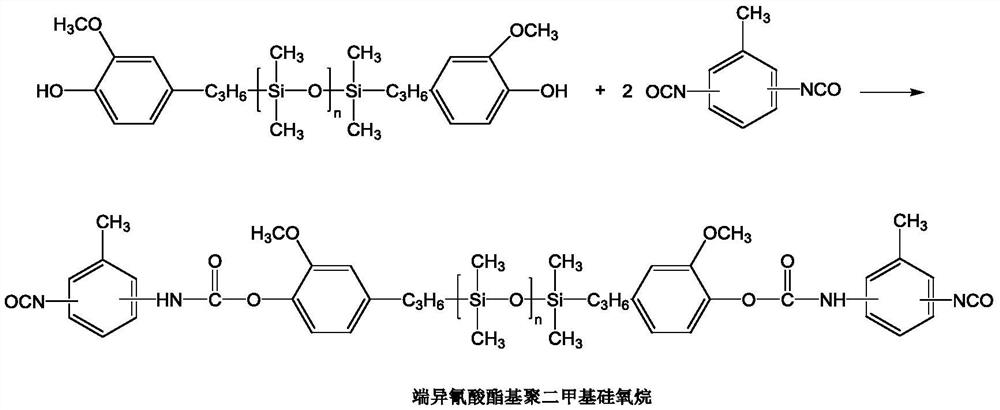

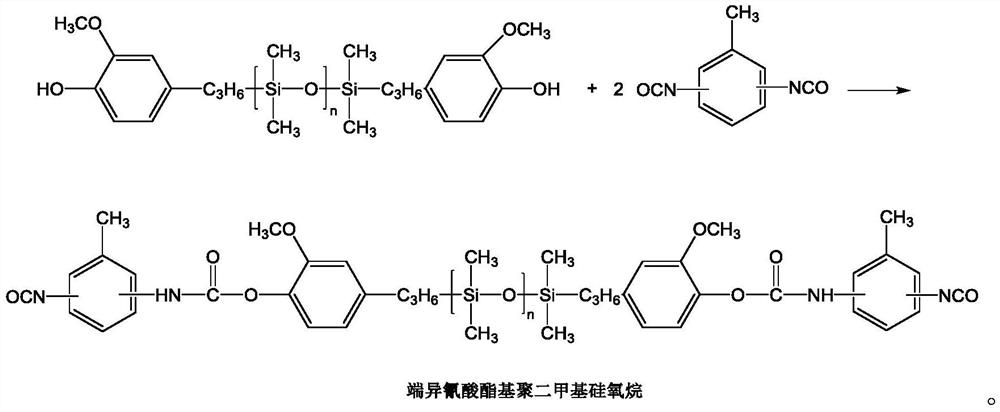

[0026] 1. Preparation of isocyanate-terminated polydimethylsiloxane: Under nitrogen protection, take 10 g of dieugenol-terminated polydimethylsiloxane into the reactor, heat to 60°C, and follow the dieugenol-terminated polydimethylsiloxane The molar ratio of polydimethylsiloxane to toluene diisocyanate (a mixture of 80% 2,4-toluene diisocyanate and 20% 2,6-toluene diisocyanate) was 1:2. Add toluene diisocyanate and stir for 3 hours. The product was protected under nitrogen and stored in cold storage for future use.

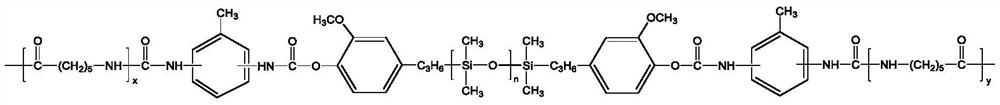

[0027] 2. Preparation of nylon 6 polydimethylsiloxane copolymer by casting method: add 100g of caprolactam monomer into the reactor, heat it at 82°C to melt it, and raise the temperature to 132°C, vacuum dehydration for 40min; release the vacuum, according to Add sodium hydroxide at a molar ratio of caprolactam to sodium hydroxide of 100:0.4, dehydrate under vacuum at 132°C for 30 minutes; release the vacuum, add isocyanate-terminated polydimethylsiloxane at a mol...

Embodiment 2

[0029] 1. Preparation of isocyanate-terminated polydimethylsiloxane: Under nitrogen protection, take 15g of dieugenol-terminated polydimethylsiloxane into the reactor, heat to 65°C, and follow the dieugenol-terminated polydimethylsiloxane The molar ratio of polydimethylsiloxane to toluene diisocyanate (a mixture of 80% 2,4-toluene diisocyanate and 20% 2,6-toluene diisocyanate) is 1:2.1. Add toluene diisocyanate and stir for 2.5 hours . The product was protected under nitrogen and stored in cold storage for future use.

[0030] 2. Preparation of nylon 6 polydimethylsiloxane copolymer by casting molding method: add 150g caprolactam monomer into the reactor, heat it at 88°C to melt it, and raise the temperature to 136°C, vacuum dehydration for 30min; release the vacuum, according to Add sodium hydroxide at a molar ratio of caprolactam to sodium hydroxide of 100:0.6, dehydrate in vacuum at 136°C for 25 minutes; release the vacuum, add isocyanate-terminated polydimethylsiloxane at...

Embodiment 3

[0032] 1. Preparation of isocyanate-terminated polydimethylsiloxane: Under the protection of nitrogen, take 18g of dieugenol-terminated polydimethylsiloxane into the reactor, heat to 70°C, and follow the dieugenol-terminated polydimethylsiloxane The molar ratio of polydimethylsiloxane to toluene diisocyanate (a mixture of 80% 2,4-toluene diisocyanate and 20% 2,6-toluene diisocyanate) was 1:2.2. Add toluene diisocyanate and stir for 2 hours. The product was protected under nitrogen and stored in cold storage for future use.

[0033] 2. Preparation of nylon 6 polydimethylsiloxane copolymer by casting method: add 200g of caprolactam monomer into the reactor, heat it at 90°C to melt it, and raise the temperature to 135°C, vacuum dehydration for 35min; release the vacuum, according to Add sodium hydroxide at a molar ratio of caprolactam to sodium hydroxide of 100:0.5, dehydrate under vacuum at 135°C for 35 minutes; release the vacuum, and add isocyanate-terminated polydimethylsilox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com