Equiaxed nanocrystalline Ti6Al4V-Mn alloy with high thermal stability and preparation method of equiaxed nanocrystalline Ti6Al4V-Mn alloy

A ti6al4v-mn, high thermal stability technology, applied in the field of titanium alloy materials, can solve the problems of small size of preparation materials, thermal stability of nanocrystalline metal materials restricting application and development, and inability to meet large-scale industrial production, etc. Thermal stability and the effect of improving comprehensive mechanical properties

Active Publication Date: 2021-01-22

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Common large plastic deformation methods include equal channel angular extrusion (ECAP), cumulative composite rolling (ARB), multidirectional forging (MF) and high pressure torsion (HPT), etc., all of which require high-power equipment and expensive molds , the size of the prepared material is also small, which cannot meet the needs of large-scale industrial production

In addition, the microstructure thermal stability of nanocrystalline metal materials is another important bottleneck restricting its application and development.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

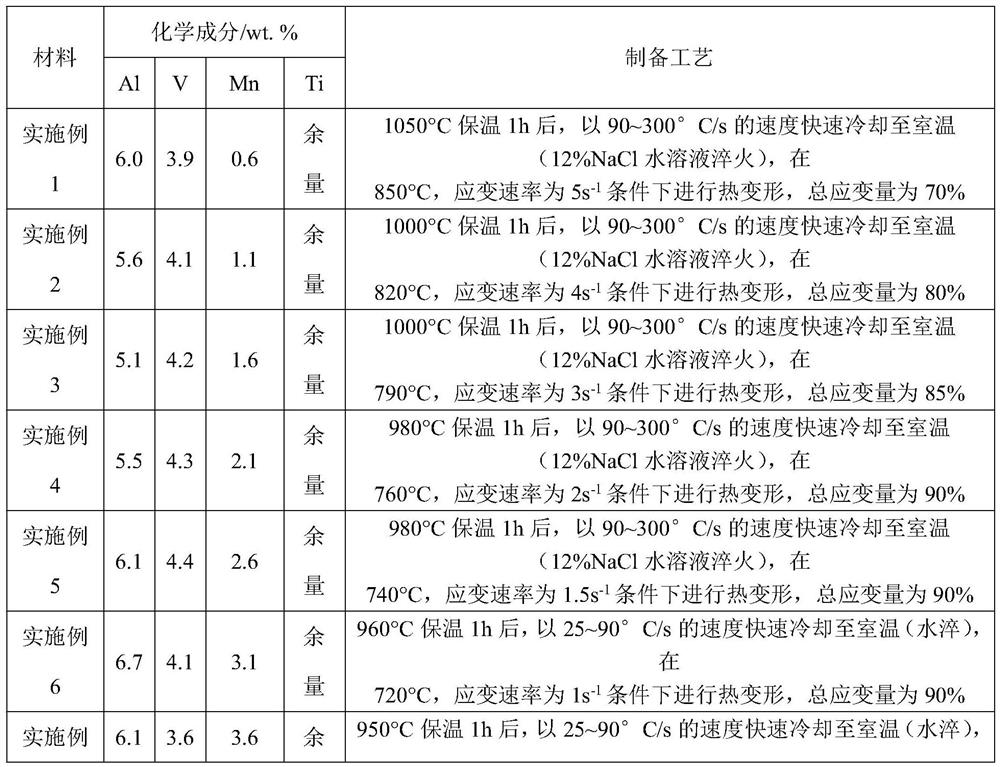

[0026] Embodiment: Examples 1 to 9 are Ti6Al4V-Mn alloys smelted according to the chemical composition range provided by the present invention, the content of the Mn element is gradually increased, and the corresponding preparation process is also properly adjusted within the scope of technical parameters specified in the present invention . The size of the prepared bulk nanocrystalline metal material is 120×120×30 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

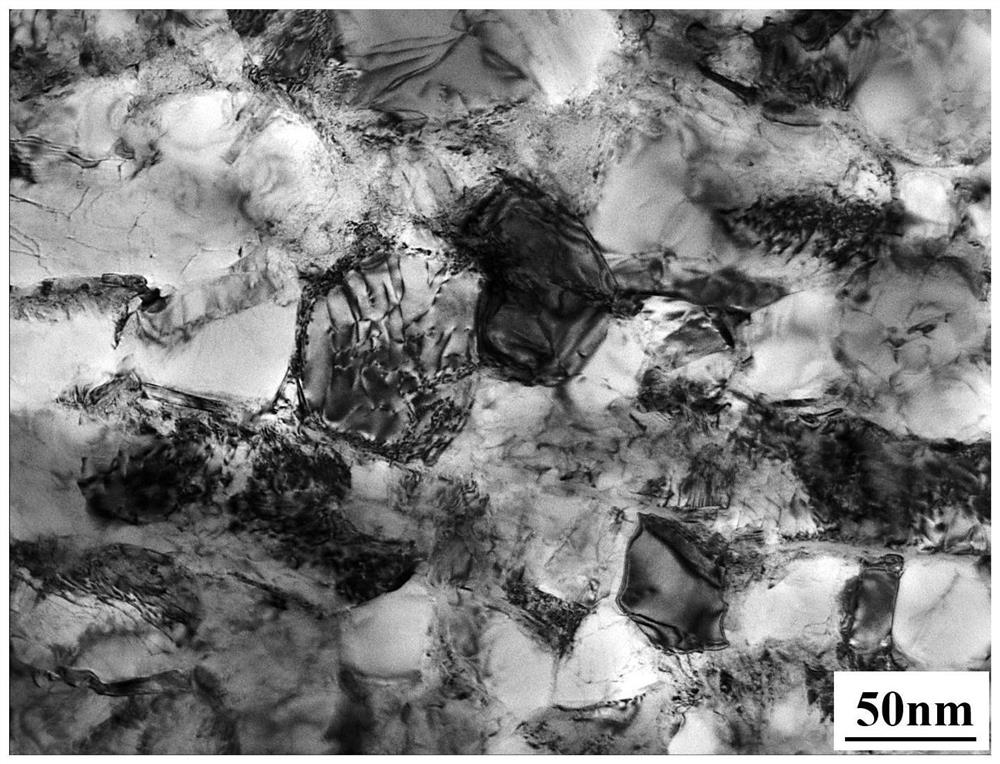

The invention relates to the field of titanium alloy materials, in particular to an isometric nanocrystalline Ti6Al4V-Mn alloy with high thermal stability and a preparation method of the isometric nanocrystalline Ti6Al4V-Mn alloy. The titanium alloy comprises, by weight, 5.0-7.0% of Al, 3.0-5.0% of V, 0.01-5.0% of Mn, and the balance Ti. The preparation method of the titanium alloy comprises the following steps that 1, after heat preservation is conducted for a period of time at the temperature of 950 DEG C or above, the titanium alloy is rapidly cooled to the room temperature to obtain a nanometer lath precursor; and 2, the nano lath precursor is subjected to thermal deformation within the temperature range of 650-850 DEG C and the strain rate range of 0.1-5s<-1>, the total dependent variable is greater than or equal to 70%, and the nano lath precursor is converted into an isometric nanocrystalline structure. The prepared nanocrystalline Ti6Al4V-Mn alloy with the high thermal stability has excellent comprehensive mechanical properties, and can be widely applied to a plurality of important fields of aerospace, biomedical treatment, petrochemical engineering, automobile industry andocean engineering.

Description

technical field [0001] The invention relates to the field of titanium alloy materials, in particular to an equiaxed nanocrystalline Ti6Al4V-Mn alloy with high thermal stability and a preparation method thereof. Background technique [0002] Due to its high strength, low density, excellent corrosion resistance and good biocompatibility, titanium alloys are widely used in important fields such as aerospace, biomedical, petrochemical, automotive and marine engineering. With the rapid development of economy and technology in recent years, it is necessary to develop new titanium alloy materials with higher performance. Compared with traditional coarse-grained titanium alloys, nanocrystalline titanium alloys have excellent comprehensive mechanical properties such as higher strength and plasticity, greater fatigue strength, and high-temperature superplasticity. Biocompatibility and many unique physical and chemical properties are very attractive in practical applications. The prep...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C14/00C22C1/02C22F1/18

CPCC22C14/00C22C1/02C22F1/183C22F1/002C22C2200/04

Inventor 王海任玲张书源杨柯

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com