Preparation and application of non-woven multifunctional diaphragm

A multi-functional, non-fabric technology, which is applied in the manufacture of hybrid capacitor separators, non-aqueous electrolyte batteries, hybrid/electric double layer capacitors, etc., can solve the problems of lack of diaphragm research and achieve excellent electrochemical performance and stability, size Thin, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

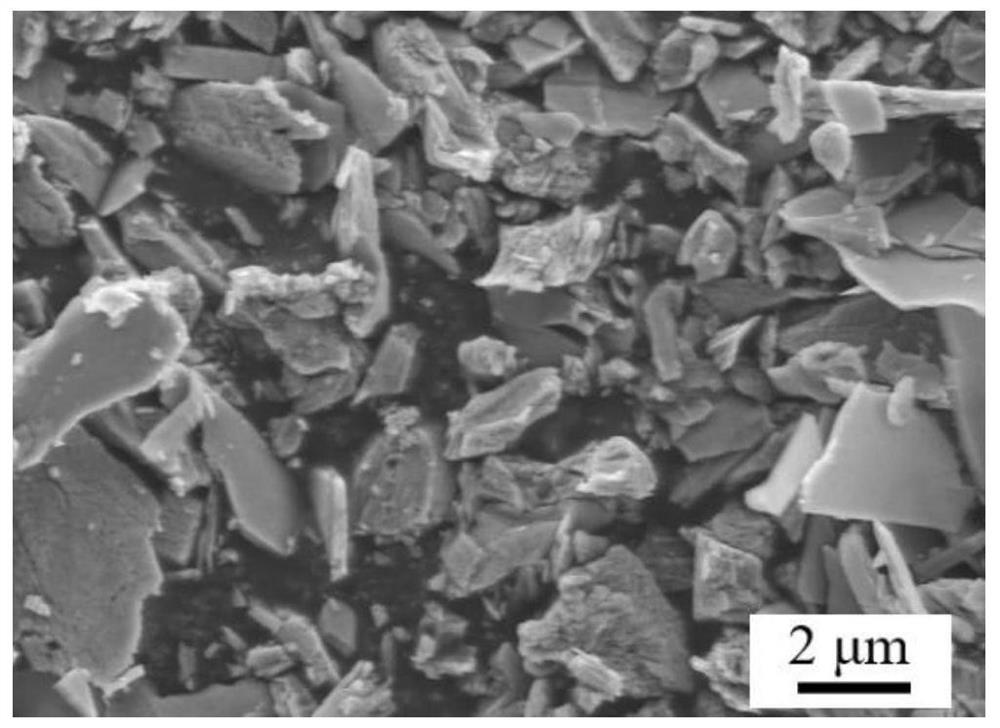

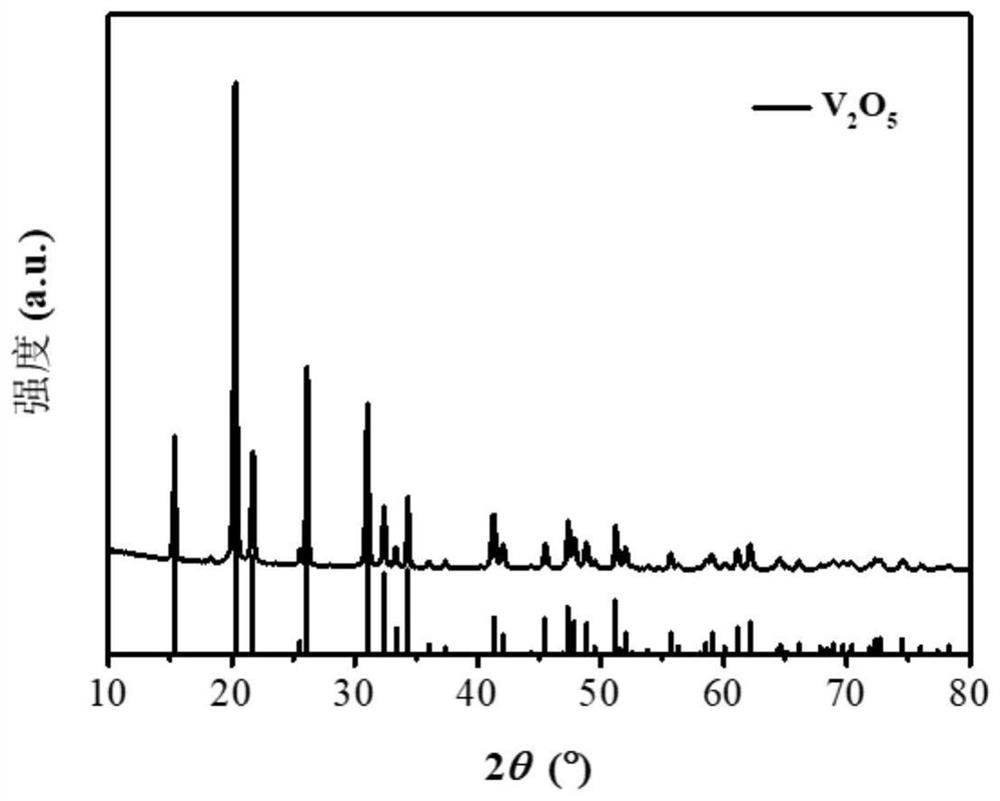

[0035] The specific implementation mode of the present invention will be further elaborated below in conjunction with description accompanying drawing and specific implementation:

[0036] Based on the preparation and testing method of a kind of non-fabric multifunctional diaphragm, concrete process is as follows:

[0037] a. Prepare a 50ml solution of deionized water and formamide with a volume ratio of 2:1, stir in a magnetic stirrer for 20min, and make it fully mixed;

[0038] b. Weigh 0.5g of commercial vanadium pentoxide medicine, pour it into the mixed solution in process a, stir in a magnetic stirrer for 1h, until the color of the solution is evenly distributed;

[0039] c. React in a hydrothermal reactor at 180°C for 12 hours;

[0040] d. The precipitate of the hydrothermal reaction was filtered through ethanol for 6 times, and the obtained filter residue was dried in a vacuum oven at 70°C for 6 hours;

[0041] e. Finally, in a muffle furnace, sinter at a high temper...

PUM

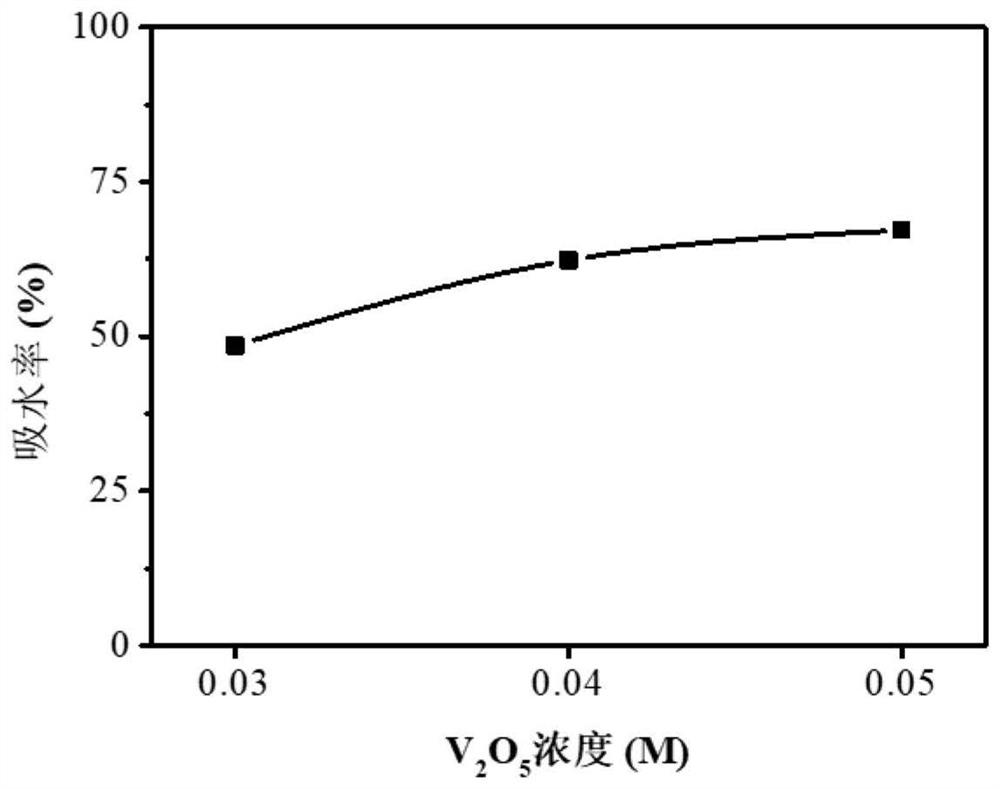

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com