Boron-phosphorus co-doped activated carbon for adsorbing aromatic-ring-containing compounds in water and preparation method of boron-phosphorus co-doped activated carbon

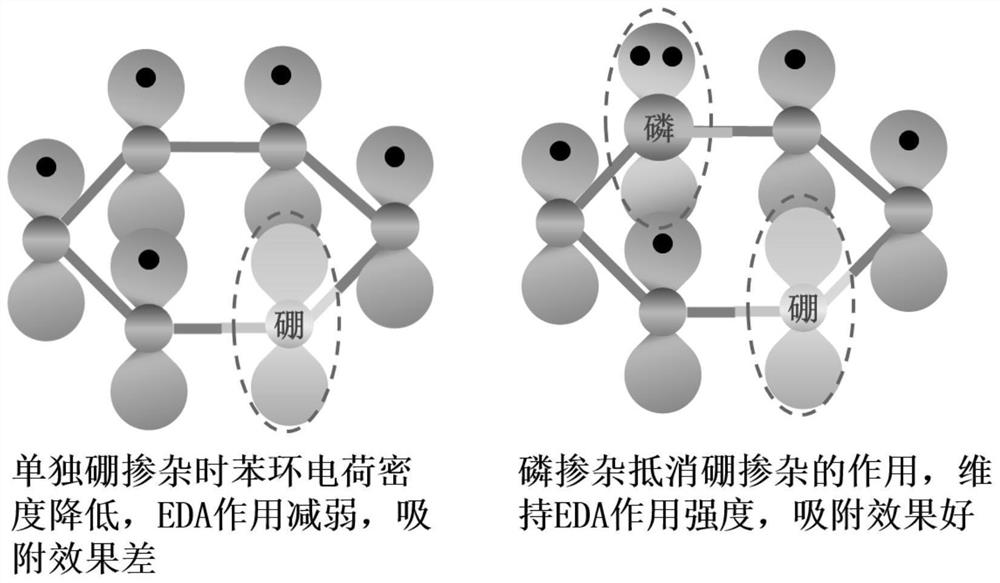

A co-doping, activated carbon technology, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve the problems of reduced aromatic ring charge density, adverse effects of aromatic ring-containing compounds adsorption, weakened EDA effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

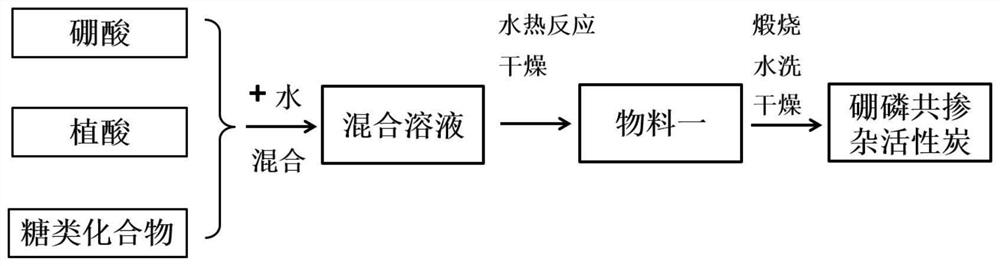

[0038] A preparation method of boron and phosphorus co-doped activated carbon, comprising the following steps:

[0039] (1) Using boric acid, phytic acid, glucose and water as raw materials, mix them in a mass ratio of 30:30:20:20;

[0040] (2) hydrothermally reacting the product obtained in step (1) at 150°C for 3h, and drying at 100°C for 18h;

[0041] (3) The product obtained in step (2) was calcined in a high-temperature furnace at 950° C. for 2 h under a helium atmosphere, then washed with water until the pH value of the clear liquid was 7, and then dried at 100° C. for 24 h to obtain boron-phosphorus co-doped activated carbon.

[0042] The boron-phosphorous co-doped activated carbon obtained by the above method has a boron doping amount of 10wt.%, a phosphorus doping amount of 8.4wt.%, and a specific surface area of 2500m 2 / g.

[0043] Application of a boron and phosphorus co-doped activated carbon in the adsorption of aromatic ring compounds in water:

[0044]Weig...

Embodiment 2

[0046] A preparation method of boron and phosphorus co-doped activated carbon, comprising the following steps:

[0047] (1) Use boric acid, phytic acid, sucrose and water as raw materials, and mix them in a mass ratio of 6:30:16:48;

[0048] (2) hydrothermally reacting the product obtained in step (1) at 250° C. for 36 hours, and drying at 95° C. for 24 hours;

[0049] (3) The product obtained in step (2) was calcined in a high-temperature furnace at 800° C. for 4 h under a nitrogen atmosphere, then washed with water until the pH value of the clear liquid was 7, and then dried at 100° C. for 16 h to obtain boron-phosphorus co-doped activated carbon.

[0050] The boron-phosphorous co-doped activated carbon obtained by the above method has a boron doping amount of 1.6wt.%, a phosphorus doping amount of 10wt.%, and a specific surface area of 2100m 2 / g.

[0051] Application of a boron and phosphorus co-doped activated carbon in the adsorption of aromatic ring compounds in wat...

Embodiment 3

[0054] A preparation method of boron and phosphorus co-doped activated carbon, comprising the following steps:

[0055] (1) Use boric acid, phytic acid, fructose and water as raw materials, and mix them in a mass ratio of 5:5:16:74;

[0056] (2) hydrothermally reacting the product obtained in step (1) at 195°C for 18h, and drying at 90°C for 16h;

[0057] (3) The product obtained in step (2) was calcined in a high-temperature furnace at 650° C. for 1 h under a nitrogen atmosphere, then washed with water until the pH value of the clear liquid was 6, and then dried at 100° C. for 24 h to obtain boron and phosphorus co-doped activated carbon.

[0058] The boron-phosphorous co-doped activated carbon obtained by the above method has a boron doping amount of 3.9wt.%, a phosphorus doping amount of 3.4wt.%, and a specific surface area of 850m 2 / g.

[0059] Application of a boron and phosphorus co-doped activated carbon in the adsorption of aromatic ring compounds in water:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com