A kind of magnetic mos applied to viscous reduction of heavy oil 2 Nanoparticle catalyst and preparation method thereof

A nanoparticle and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, earthwork drilling and mining, etc., can solve the problems of difficult recovery and easy agglomeration of catalysts, and achieve the effects of low cost, difficult agglomeration and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

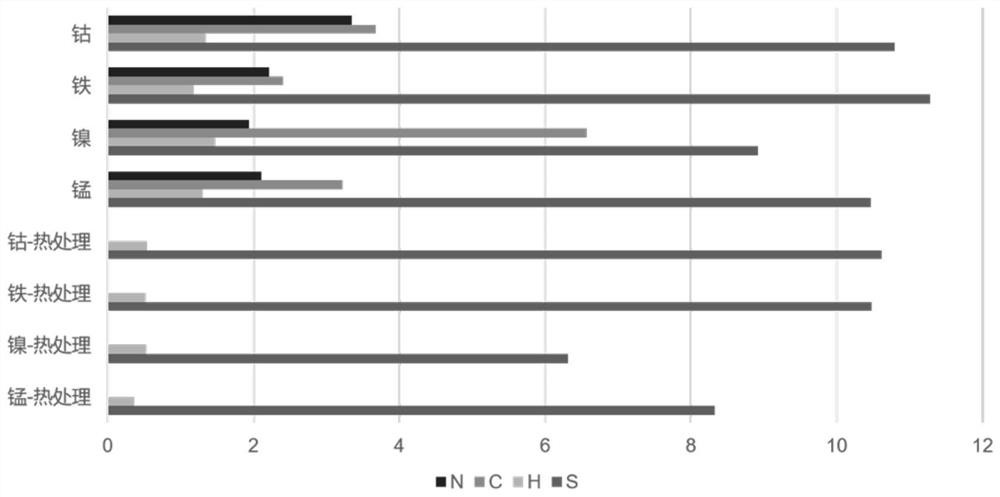

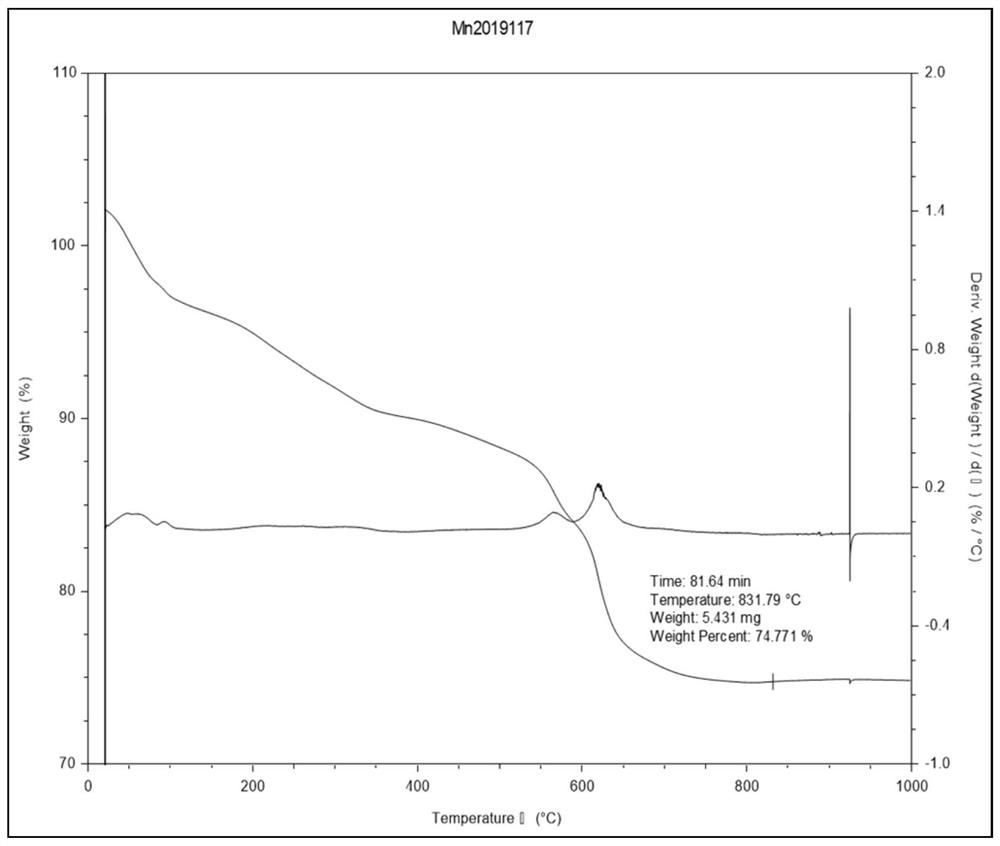

[0062] Weigh 2.5002g of sodium molybdate dihydrate into a round bottom flask, add 1.0013g of thiourea, 0.4993g of manganese acetate tetrahydrate and 100mL of paraffin oil; heat and reflux in an oil bath at 240°C for 120 minutes; after the reaction is complete, turn off the power, Naturally cooled to room temperature; the reaction mixture was suction filtered to obtain a filter cake, which was vacuum-dried at 45°C and ground to obtain 1.8200 g of a solid whose thermogravimetric analysis curve was shown in the attached figure 2 shown.

Embodiment 2

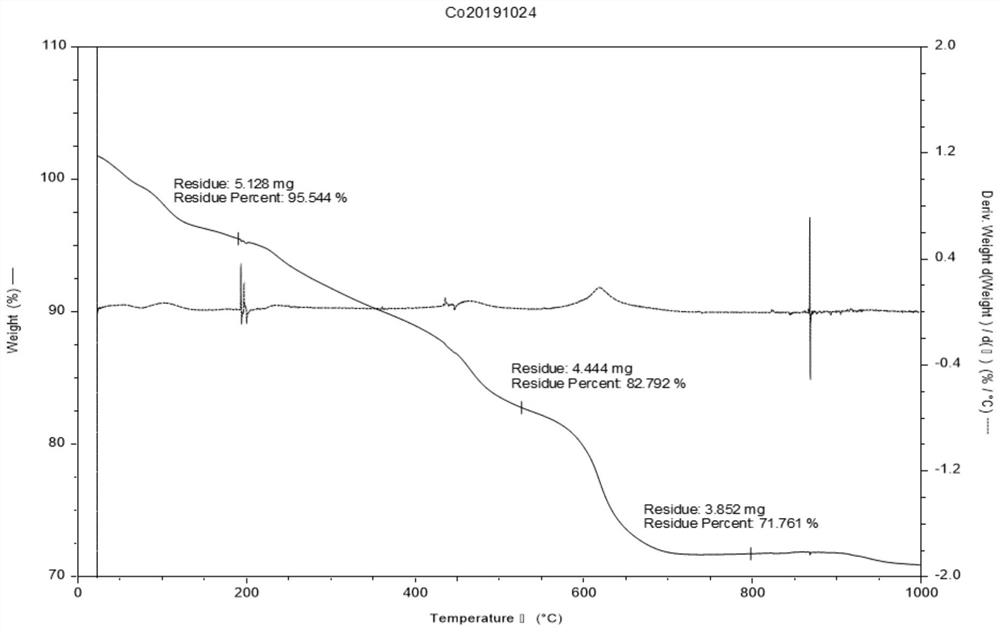

[0064] Weigh 2.4998g of sodium molybdate dihydrate into a round bottom flask, add 0.9991g of thiourea, 0.5008g of cobalt acetate tetrahydrate and 100mL of paraffin oil; heat and reflux in an oil bath at 240°C for 120 minutes; after the reaction is complete, turn off the power, Naturally cooled to room temperature; the reaction mixture was suction-filtered to obtain a filter cake, which was vacuum-dried at 45° C. and ground to obtain 2.3462 g of a solid, whose thermogravimetric analysis curve was as attached image 3 shown.

Embodiment 3

[0066] Weigh 2.5001g of sodium molybdate dihydrate into a round bottom flask, add 0.9999g of thiourea, 0.5000g of ferrous acetate and 100mL of paraffin oil; heat and reflux in an oil bath at 240°C for 120 minutes; after the reaction is complete, turn off the power and let it cool naturally to room temperature; the reaction mixture was suction-filtered to obtain a filter cake, which was vacuum-dried at 45° C. and ground to obtain 2.6099 g of a solid whose thermogravimetric analysis curve was as attached Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com