Multifunctional natural super-hydrophobic material and application thereof

A super-hydrophobic and multi-functional technology, applied in wax coatings, anti-corrosion coatings, coatings, etc., can solve the problems that fluorocarbons cannot be applied, are not flat, etc., and achieve the effect of resisting adhesion and reducing water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

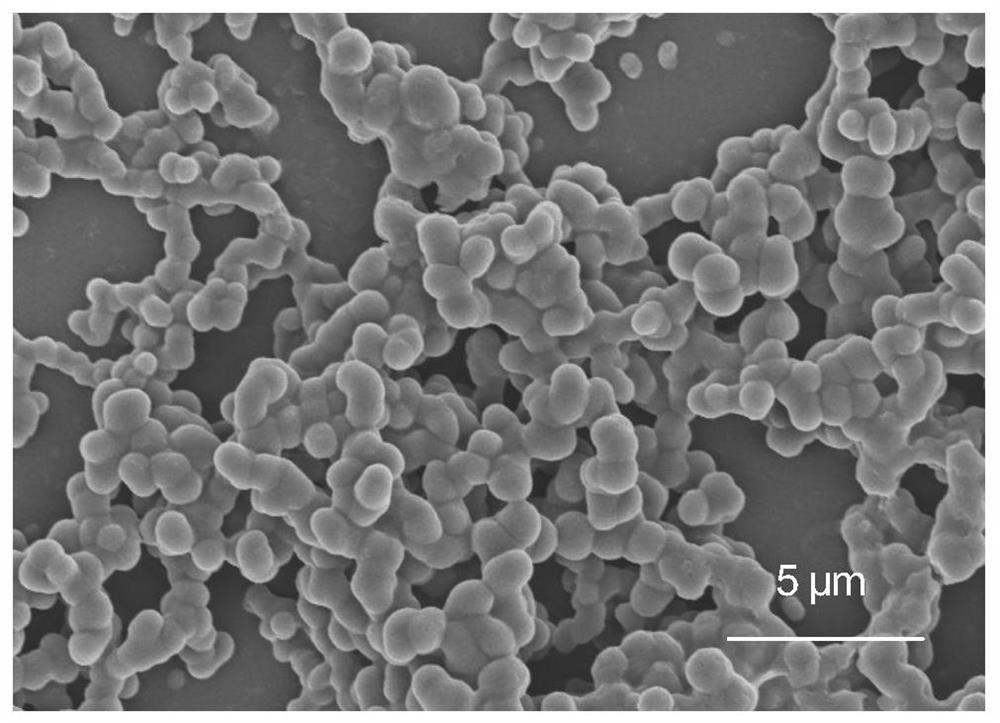

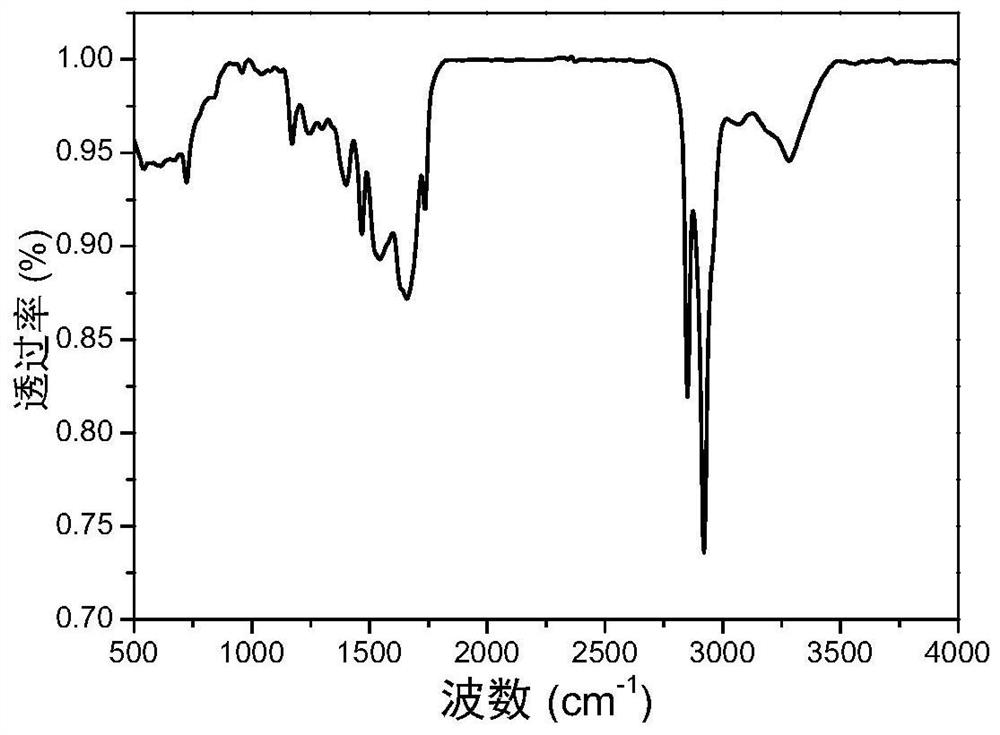

[0062] 1. At room temperature, add 140mg of L-cysteine into 10mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 10 with 5mol / L aqueous sodium hydroxide solution. Add 10 mL of lysozyme to 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then mix the two solutions evenly to obtain a mixed solution; drop the mixed solution on a silicon chip and incubate at room temperature for 2 hours , forming a phase transition product of lysozyme on the silicon wafer surface (see figure 1 ).

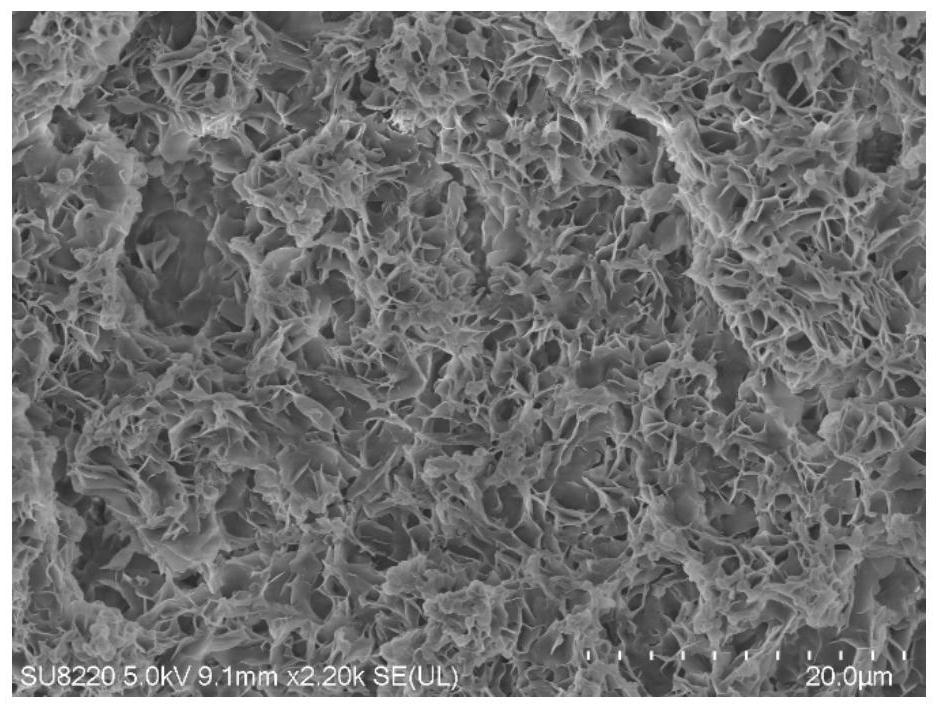

[0063] 2. On the lysozyme phase transition product of step 1, spin-coat the normal hexane solution of 6mg / mL palm wax, after the normal hexane is completely volatilized, obtain the lysozyme phase transition product of modified palm wax (see figure 2 and image 3 ), the natural superhydrophobic coating.

Embodiment 2

[0065] 1. At room temperature, add 280mg of L-cysteine into 10mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 10 with 5mol / L aqueous sodium hydroxide solution. Lysozyme was added to 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then the two solutions were mixed uniformly to obtain a mixed solution; the mixed solution was added dropwise to the polyethylene terephthalate , incubated at room temperature for 2 hr, the lysozyme phase transition product was formed on the polyethylene terephthalate surface.

[0066] 2. Spin-coat 15 mg / mL palm wax n-hexane solution on the lysozyme phase transition product in step 1. After the n-hexane is completely volatilized, the lysozyme phase transition product modified palm wax is obtained, that is, the natural superhydrophobic coating.

[0067] Figure 4 It means that the superhydrophobic coating is placed between 240-grit sandpaper and a 200g...

Embodiment 3

[0069] 1. At room temperature, add 500mg of L-cysteine to 10mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4 and adjust the pH to 9 with 5mol / L aqueous sodium hydroxide solution. Lysozyme was added to 10 mL of 4-hydroxyethylpiperazineethanesulfonic acid buffer solution with a pH of 7.4, and then the two solutions were mixed evenly to obtain a mixed solution; the mixed solution was added dropwise on a quartz plate, and incubated at room temperature for 2 hours, The lysozyme phase transition product was formed on the surface of the quartz plate.

[0070] 2. Spin-coat 3 mg / mL candelilla wax n-hexane solution on the lysozyme phase transition product in step 1. After the n-hexane is completely volatilized, the lysozyme phase transition product of modified beeswax is obtained, that is, the natural superhydrophobic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com