Process for recovering waste rare-earth water and fully cyclic treatment

A process method and wastewater recycling technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of purification purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

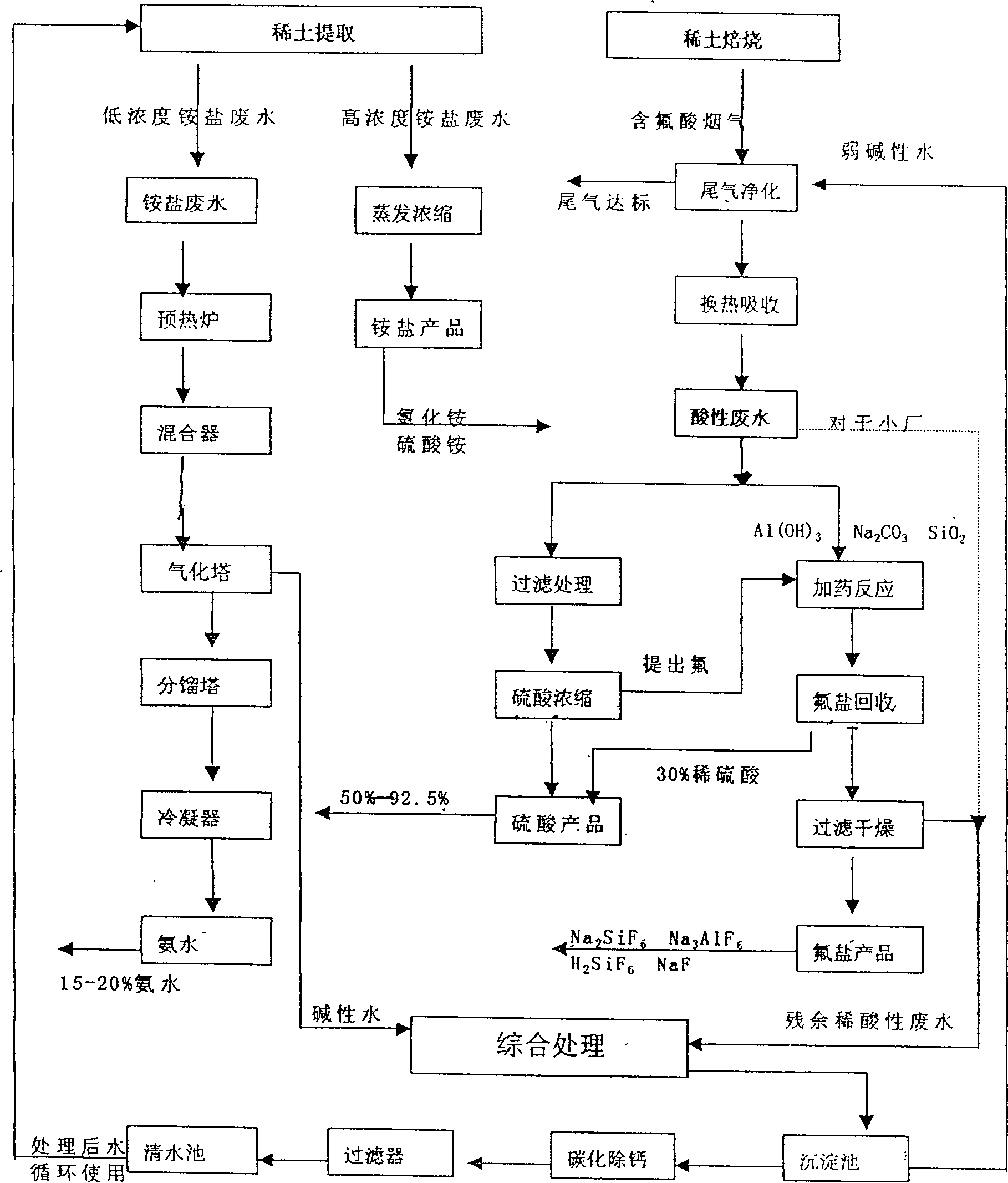

[0015] Such as figure 1 As shown, the technical method of rare earth wastewater recovery and full cycle treatment of the present invention mainly includes the ammonium salt wastewater and acidic wastewater produced in the rare earth extraction and rare earth roasting techniques for classified recovery and comprehensive treatment. The specific methods are as follows:

[0016] First, the 8000-30000mg / L low-concentration ammonium salt wastewater produced by the rare earth extraction production process is 30-50m 3 The flow rate of / n is pumped into a tubular heating furnace fueled by coal (oil, gas), and preheated to above 60-80°C, and then add about 10-20% lime milk solution through a high-efficiency mixer 0.2-0.5m 3 The flow rate of / n enters the gasification tower, and the ammonium in the waste water is converted into ammonia gas through the distribution plate and atomization into the fractionation tower, and then controlled by the condenser to recover 15-20% ammonia water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com