A kind of preparation method of ultra-small silver sulfide quantum dots

A technology of silver sulfide and quantum dots, applied in the field of nanomaterials, can solve the problems of small size preparation and size regulation difficulty, poor dispersion of silver sulfide quantum dots, etc., and achieve the effects of high reproducibility, good crystallinity and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, 0.6 g single-source precursor silver N,N-diethyldithiocarbamate (AgS 2 CN(C 2 h 5 ) 2 ) powder was ultrasonically dispersed into 90 g of N,N-dimethylformamide / N-methylpyrrolidone mixed solvent (1:1 volume ratio), and then poured into a polytetrafluoroethylene reactor; at 240°C After cooling for 120 min, the reaction solution was centrifuged at 6000 rpm for 10 min to separate the product. The product was washed with a mixed solvent of N,N-dimethylformamide and N-methylpyrrolidone several times and then washed with absolute ethanol. The washed product was finally dried at 60°C for 2 hours to obtain silver sulfide quantum dots. Perform XRD analysis on the dried powder sample, and re-disperse it ultrasonically into the above mixed solvent for TEM test.

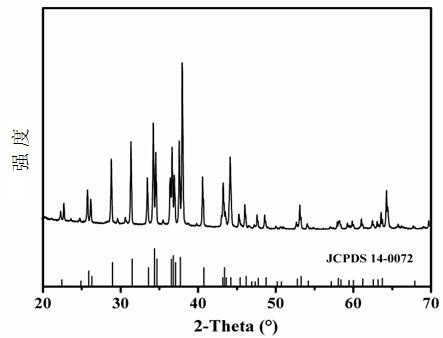

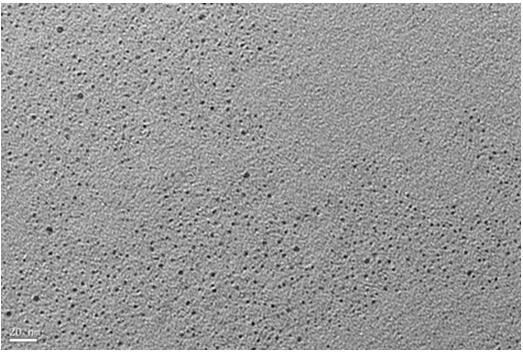

[0023] XRD and TEM of silver sulfide quantum dots such as figure 1 , figure 2 shown. figure 1 It shows that the material synthesized by thermal decomposition of single-source precursor is silver sulfide cryst...

Embodiment 2

[0025] First, 0.7 g single-source precursor silver N,N-dibutyldithiocarbamate (AgS 2 CN(C 4 h 9 ) 2 ) powder was ultrasonically dispersed into 90 g of N,N-dimethylformamide / N-methylpyrrolidone mixed solvent (1:1 volume ratio), and then poured into a polytetrafluoroethylene reactor; at 240°C After cooling for 120 min, the reaction solution was centrifuged at 6000 rpm for 10 min to separate the product. The product was washed with a mixed solvent of N,N-dimethylformamide and N-methylpyrrolidone several times and then washed with absolute ethanol. The washed product was finally dried at 60°C for 2 hours to obtain silver sulfide quantum dots. The dried powder sample was re-dispersed ultrasonically into the above mixed solvent for TEM testing.

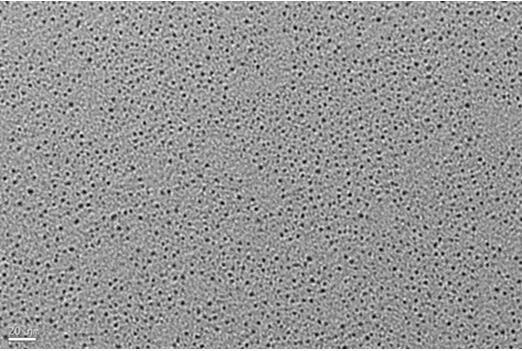

[0026] TEM of silver sulfide quantum dots as image 3 shown. image 3 It shows that the size of the synthesized silver sulfide quantum dots is very small, ranging from 1.4 to 2.3 nm, and the dispersion is very uniform.

Embodiment 3

[0028] First, 0.9 g single-source precursor silver N,N-di-n-hexyldithiocarbamate (AgS 2 CN(C 6 h 13 ) 2 ) powder was ultrasonically dispersed into 90 g of N,N-dimethylformamide / N-methylpyrrolidone mixed solvent (1:1 volume ratio), and then poured into a polytetrafluoroethylene reactor; at 240°C After cooling for 120 min, the reaction solution was centrifuged at 6000 rpm for 10 min to separate the product. The product was washed with a mixed solvent of N,N-dimethylformamide and N-methylpyrrolidone several times and then washed with absolute ethanol. The washed product was finally dried at 60°C for 2 hours to obtain silver sulfide quantum dots. The dried powder was re-dispersed ultrasonically into the above mixed solvent for TEM testing.

[0029] TEM of silver sulfide quantum dots as Figure 4 shown. Figure 4 It shows that the size of the synthesized silver sulfide quantum dots is very small, ranging from 0.9 to 1.9 nm, and the dispersion is very uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com