Fluorescent colloid, high-luminous-efficiency light source and manufacturing method of high-luminous-efficiency light source

A high light efficiency, phosphor technology, applied in the field of fluorescent colloids, can solve the problems of low temperature resistance of silicone resin, low thermal conductivity, low reflectivity, etc., and achieve the effect of reducing the use power, small particles, and reducing quality variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

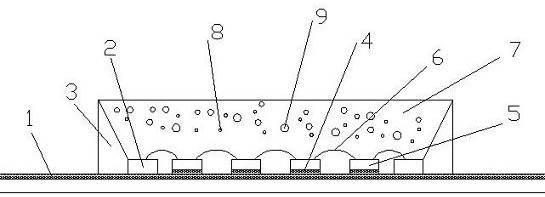

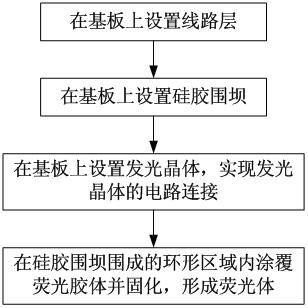

[0034] The invention discloses a fluorescent colloid, which is mainly used for the packaging of LED light sources. It is formed by uniformly mixing various raw materials. The raw materials include or mainly include fluorescent powder and silica gel. According to the different color ratios of the fluorescent powder, the The mass ratio of the fluorescent powder to the silica gel is (0.05-0.7):(1.2-1.8). As the color temperature decreases, the CIE coordinate value increases, and the proportion of phosphor increases accordingly, or the proportion of silica gel decreases accordingly.

[0035] The raw material also preferably includes fumed silica, which is uniformly mixed with the fluorescent powder and the silica gel, and the mass ratio of the fumed silica in the fluorescent colloid (fumed silica The proportion relative to the total mass) is 0.5%-2%. The mass proportion of the fumed silica in the fluorescent colloid can be flexibly adjusted according to the ratio of the phosphor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com