Space laser film preparation method

A laser thin film and space technology, which is applied in vacuum evaporation coating, coating, sputtering coating, etc., can solve the problems of poor stability of laser thin film, achieve reduced surface and subsurface defects, small spectral shift, high The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

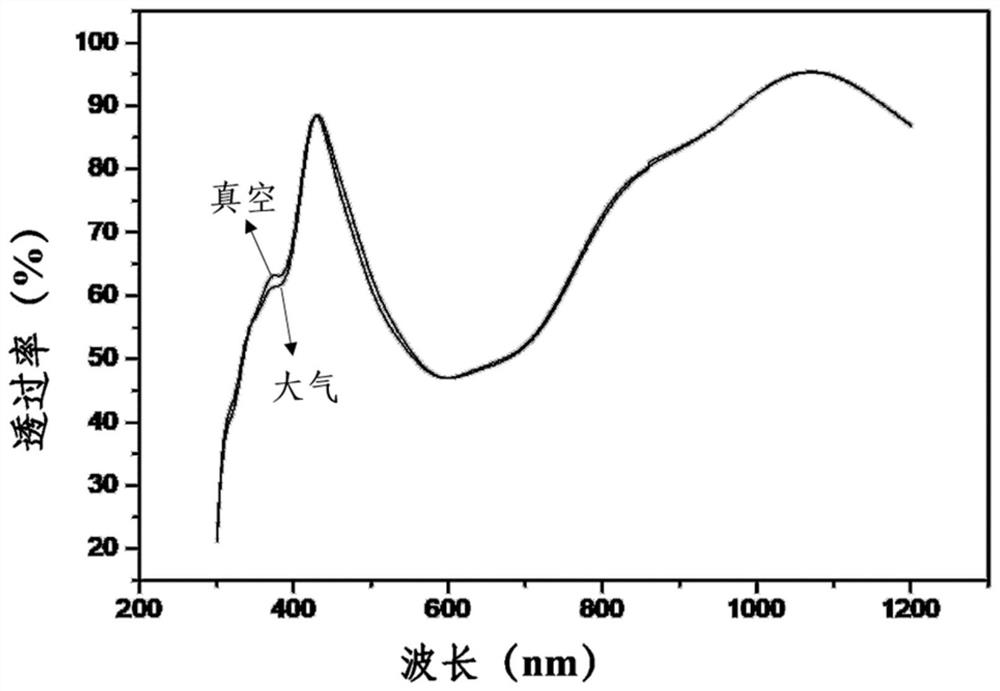

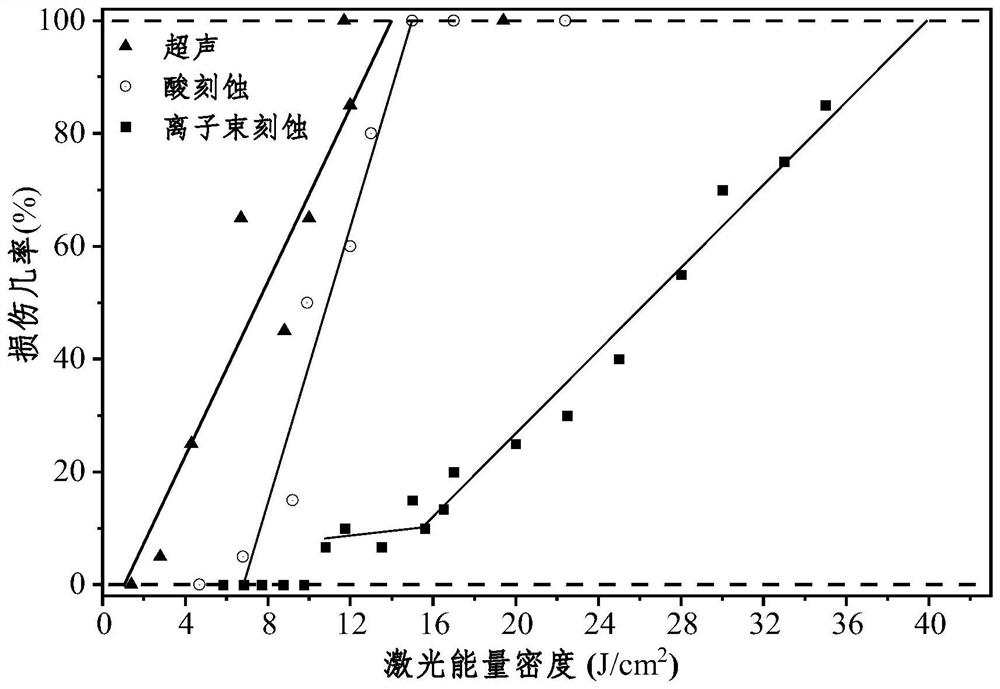

[0033] Embodiment 1: take quartz glass as substrate, Al 2 o 3 For the film material, SiO 2 Prepare a 1064nm AR coating for the protective layer material.

[0034] Clean the substrate ultrasonically for 10-30 minutes, then rinse it with deionized water, and finally dry it with high-purity nitrogen; scrub the vacuum chamber inside the coating machine, and perform vacuum pumping; put the substrate into the coating machine, and close the vacuum chamber door , carry out vacuum pumping again, and control the background vacuum degree of the vacuum chamber in the coating machine to be 2×10 -6 Pa, heating the substrate to keep the temperature at 80°C; ion beam etching is performed on the substrate before coating, and the Ar ion source is used to bombard the substrate, the Ar ion source voltage used is 650V, and the etching depth is 200nm; dual ion beam sputtering is used The equipment is used to coat the above-mentioned treated substrates, the main ion source voltage is 1250V, argon...

Embodiment 2

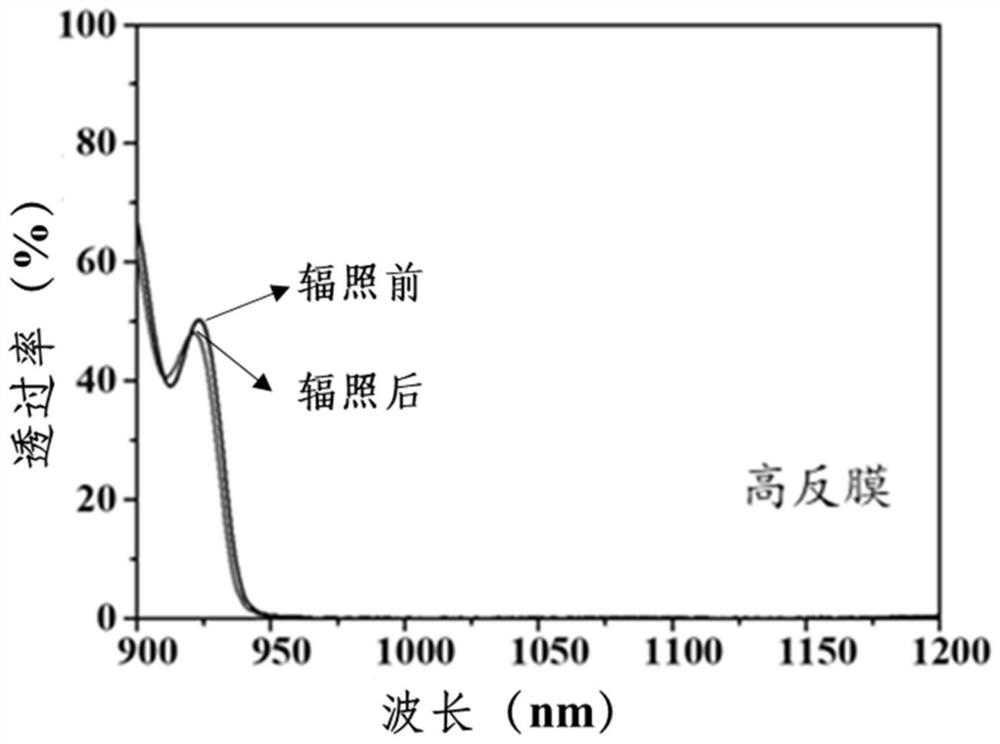

[0037] Embodiment 2: take quartz glass as substrate, Ta 2 o 5 For the film material, SiO 2 Prepare a high reflection film for the protective layer material.

[0038] Clean the substrate ultrasonically for 10-30 minutes, then rinse it with deionized water, and finally dry it with high-purity nitrogen; scrub the vacuum chamber inside the coating machine, and perform vacuum pumping; put the substrate into the coating machine, and close the vacuum chamber door , carry out vacuum pumping again, and control the background vacuum degree of the vacuum chamber in the coating machine to be 2×10 -6 Pa, heating the substrate to keep its temperature at 80°C; ion beam etching is performed on the substrate before coating, the substrate is bombarded with Ar ion source, the voltage of Ar ion source is 650V, and the etching depth is 200nm; dual ion beam sputtering equipment is used Coating on the above treated substrate, the main ion source voltage is 1250V, using argon as the main ion sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com