Preparation method of vaterite-containing hydrogel scaffold material

A scaffold material, vaterite technology, applied in prosthesis, tissue regeneration, medical science and other directions, can solve the problem of inability to provide an extracellular matrix environment, and achieve the effect of promoting bone growth, good mechanical properties, and easy process amplification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of Vaterite-rich Novel Hydrogel Scaffolding Materials

[0027] Step 1: Preparation of Vaterite

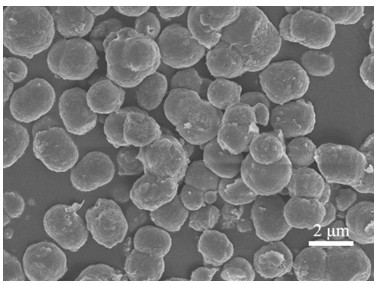

[0028] Prepare Na at a concentration of 50 mM 2 CO 3 50 mL of the solution, and 0.1 g of casein was added to it to fully dissolve. Under stirring at 600 r / min, the Na 2 CO 3 Transfer the casein / casein solution to 50 mM CaCl 2 The solution was placed in 50 mL of the solution, stirred for 20 min, and the precipitate was collected by centrifugation. Then, it was washed three times with deionized water, and the precipitate was freeze-dried. It was detected by XRD that the obtained precipitate was vaterite. The SEM image ( figure 1 ) shows that vaterite is spherical particles with a diameter of 1–3 μm.

[0029] Step 2: Preparation of new vaterite-rich hydrogel scaffolds

[0030] The gelatin was dissolved in water at 40 °C to prepare a solution of 100 mg / mL. The mass ratio of vaterite to gelatin was 1:10, and 10 mg of vaterite was added to the gelatin ...

Embodiment 2

[0032] Example 2 Preparation of Vaterite-rich Novel Hydrogel Scaffolding Materials

[0033] Step 1: Preparation of Vaterite

[0034] Prepare Na at a concentration of 60 mM 2 CO 3 The solution was 50 mL, and 0.3 g of casein was added to it to fully dissolve. Under stirring at 600 r / min, the Na 2 CO 3 Transfer the casein / casein solution to 60 mM CaCl 2 The solution was stirred for 20 min in 50 mL, the precipitate was collected by centrifugation, washed with deionized water for 3 times, and the precipitate was freeze-dried to obtain vaterite. The results were similar to those obtained in Example 1.

[0035] Step 2: Preparation of new vaterite-rich hydrogel scaffolds

[0036] Dissolve gelatin in 40°C water to prepare a solution of 200 mg / mL, add 15 mg of vaterite to the gelatin solution with a mass ratio of vaterite to gelatin of 1:15, and disperse uniformly under stirring at 600 r / min. The gelatin solution containing vaterite was poured into the mold, aged at 10 °C for 12 ...

Embodiment 3

[0037] Example 3 Preparation of a novel hydrogel scaffold rich in vaterite

[0038] Step 1: Preparation of Vaterite

[0039]Prepare Na at a concentration of 80 mM 2 CO 3 50 mL of the solution, and 0.4 g of casein was added to it to fully dissolve. Under stirring at 600 r / min, the Na 2 CO 3 Transfer the casein / casein solution to 80 mM CaCl 2 The solution was stirred for 20 min in 50 mL, the precipitate was collected by centrifugation, washed with deionized water for 3 times, and the precipitate was freeze-dried to obtain vaterite. The results were similar to those obtained in Example 1.

[0040] Step 2: Preparation of new vaterite-rich hydrogel scaffolds

[0041] The gelatin was dissolved in water at 40°C to prepare a solution of 300 mg / mL. The mass ratio of vaterite to gelatin was 1:20, and 20 mg of vaterite was added to the gelatin solution, and the mixture was uniformly dispersed under stirring at 600 r / min. The gelatin solution containing vaterite was poured into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com