Transparent composite PI film, transparent composite PI substrate containing PI film and preparation method of transparent composite PI substrate

A composite and transparent technology, applied in chemical instruments and methods, flat products, and other household appliances, etc., it can solve the problem of difficulty in making ultra-thin 5-15um films, the impact of optical properties such as transmittance, haze, etc. The influence of optical properties such as transmittance and haze has achieved the effect of enhancing the yellowing resistance of irradiation, a wide range of thickness, and sufficient mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

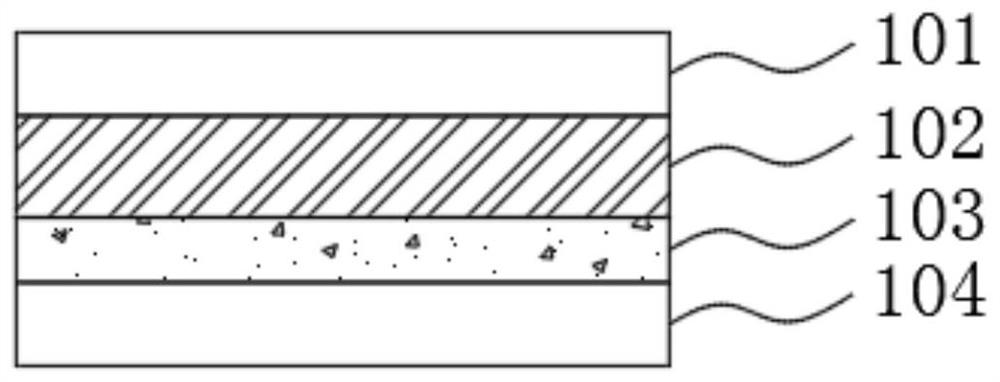

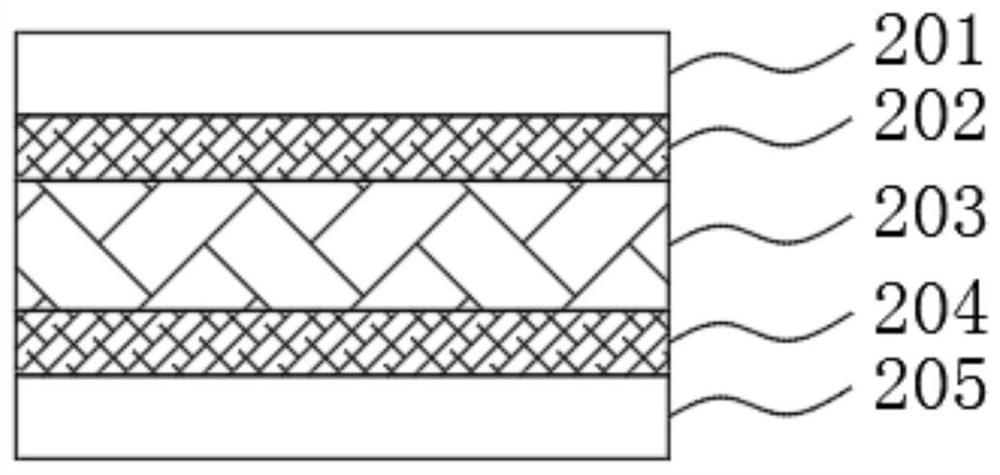

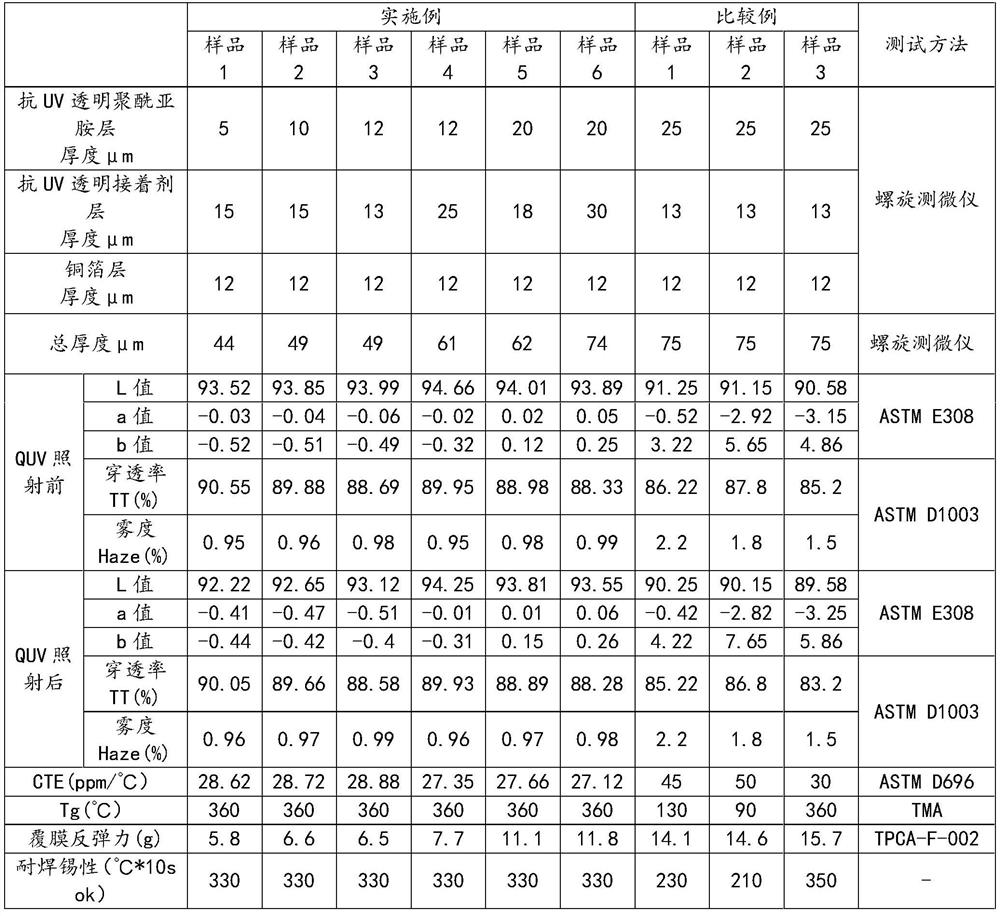

[0046] Embodiment: a kind of transparent composite PI film, comprises anti-UV transparent polyimide layer 102 and anti-UV transparent adhesive layer 103;

[0047] The light transmittance of the transparent composite PI film is >88% and the haze is 4H, CTE<30ppm;

[0048] The glass transition temperature of the anti-UV transparent polyimide layer 102 is >320°C;

[0049] The thickness of the transparent composite PI film is 8-70 μm; wherein, the thickness of the anti-UV transparent polyimide layer 102 is 3-20 μm; the thickness of the anti-UV transparent adhesive layer 103 is 5-50 μm.

[0050] The anti-UV transparent polyimide layer 102 is a transparent polyimide varnish layer containing an anti-UV absorber.

[0051] The anti-UV transparent adhesive layer 103 is an acrylic adhesive layer or a polyester adhesive layer.

[0052] The anti-UV transparent adhesive layer 103 is a polyester adhesive layer, and the polyester adhesive layer includes an organic component B, a low-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com