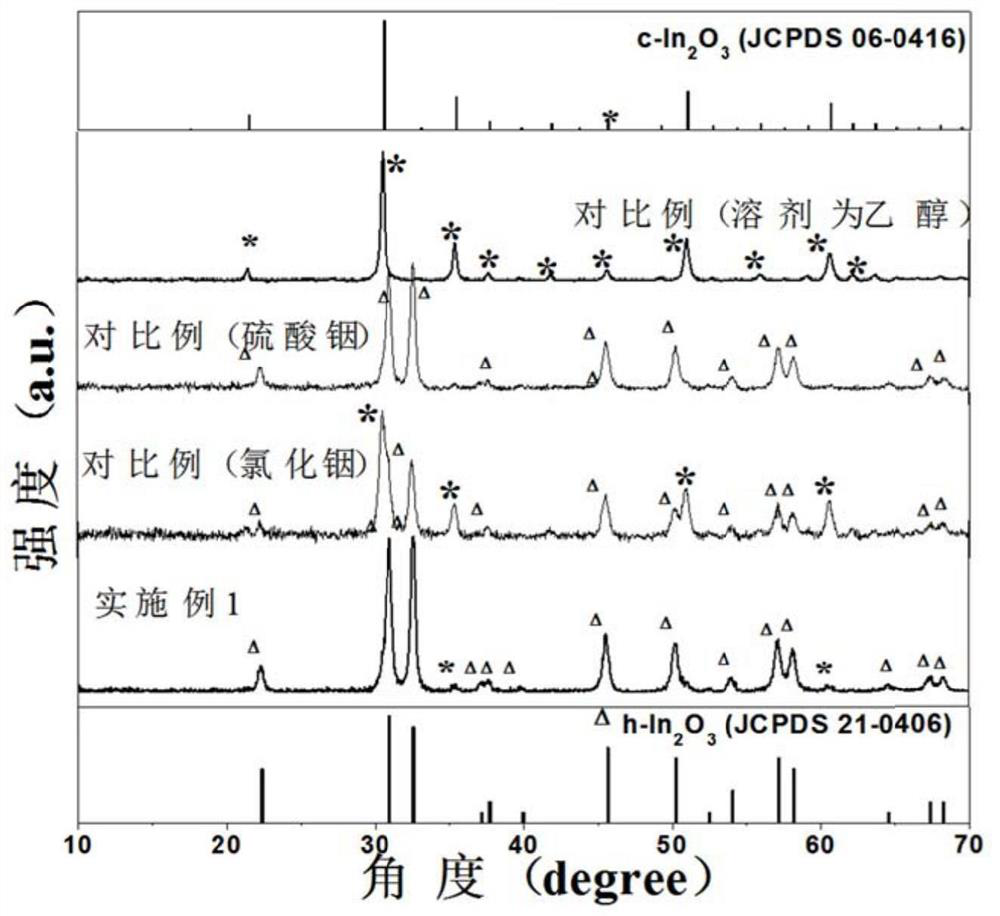

Nano bicrystal-phase indium oxide gas-sensitive material as well as preparation method and application thereof

A nano-twin and indium oxide technology, applied in chemical instruments and methods, analytical materials, material resistance, etc., can solve problems that are not conducive to shape and crystal form regulation, unfavorable industrial production, complicated preparation process, etc., and achieve industrial prospects Good, cheap preparation raw materials, simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

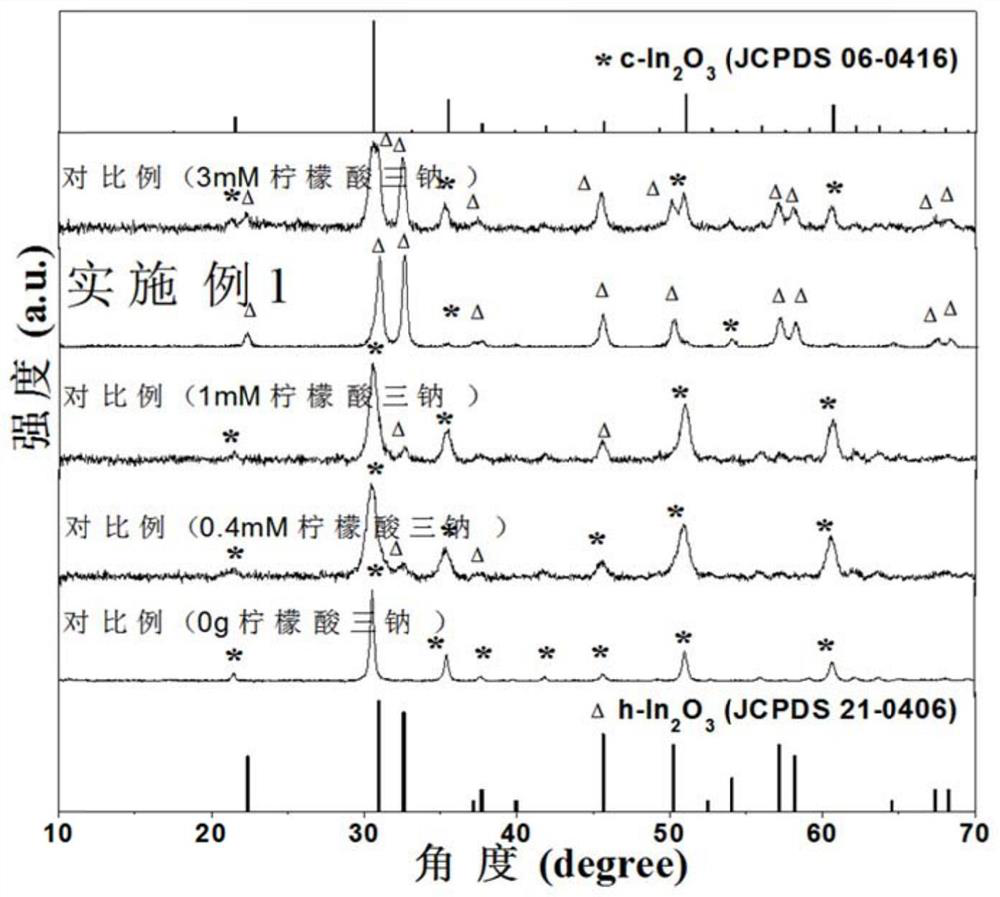

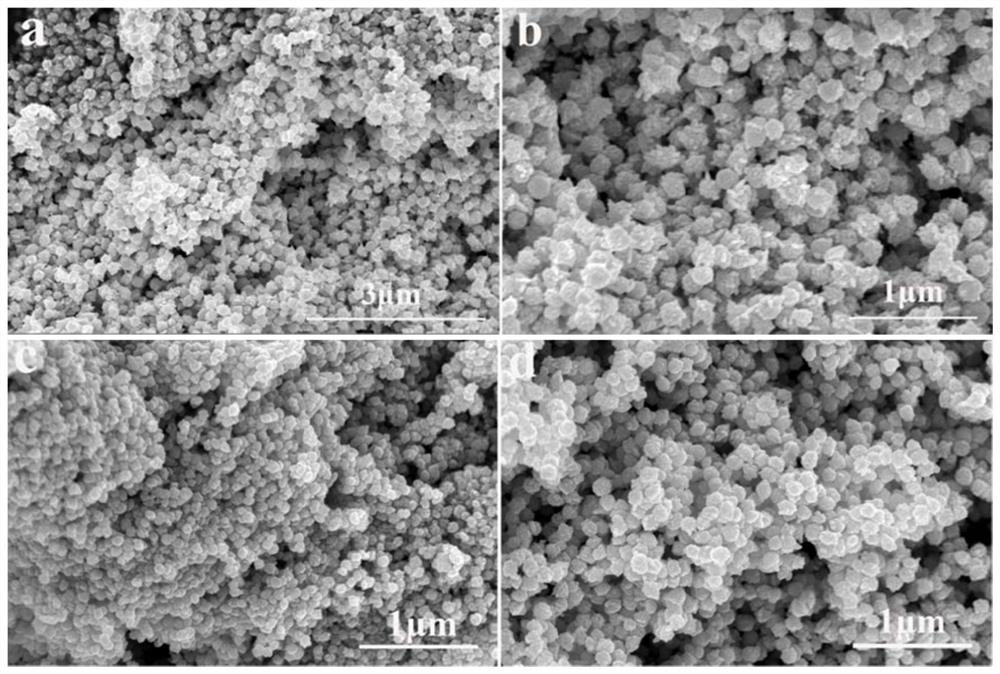

Embodiment 1

[0033] Weigh 2mM trisodium citrate into the beaker, then add 30 ml of deionized water; stir the above solution with a glass rod until it is completely dissolved, then add 1.0 mmol In(NO 3 ) 3 4.5H 2 O and 3.0 mmol urea; magnetically stir the above prepared solution for 30 min until completely dissolved; put the above stirred solution into a high-pressure reactor and heat it for 8 hours; after the reaction, cool and centrifuge, wash with deionized water three times It was washed twice with absolute ethanol, dried and calcined at 450° C. for 3 h in a muffle furnace before being collected and utilized.

[0034] Pour an appropriate amount of the annealed sample into an agate mortar, add an appropriate amount of terpineol to the sample and grind it gently and fully to make it into a uniform paste. Put a toothpick in the middle of the ceramic tube for fixation, then use tweezers to straighten the platinum wire on the ceramic tube, and use a pre-sharpened bamboo stick to evenly sme...

Embodiment 2

[0036] Weigh 0.5mM trisodium citrate into the beaker, then add 30 ml of deionized water; stir the above solution with a glass rod until it is completely dissolved, then add 2.0 mmol InCl 3 4H 2 O and 2.0 mmol urea; magnetically stir the above prepared solution for 30 min until it is completely dissolved; put the above stirred solution into a high-pressure reactor at 150°C for hydrothermal reaction for 10 h; after the reaction, cool and centrifuge, and deionize After washing with water three times and then with absolute ethanol twice, after drying, it was calcined at 400°C for 5 hours in a muffle furnace and collected for use.

[0037]Pour an appropriate amount of the annealed sample into an agate mortar, add an appropriate amount of terpineol to the sample and grind it gently and fully to make it into a thick and suitable paste. Put a toothpick in the middle of the ceramic tube for fixation, then use tweezers to straighten the platinum wire on the ceramic tube, and use a pre-...

Embodiment 3

[0039] Weigh 5mM trisodium citrate into the beaker, then add 30 ml of deionized water; stir the above solution with a glass rod until it is completely dissolved, then add 5.0 mmol In(NO 3 ) 3 4.5H 2 O and 1.0 mmol urea; magnetically stir the above prepared solution for 30 min until it is completely dissolved; put the above stirred solution into a high-pressure reactor at 150°C for hydrothermal reaction for 15 h; after the reaction, cool and centrifuge, and deionize After washing with water three times and then with absolute ethanol twice, after drying, it was calcined in a muffle furnace at 500°C for 1 hour, and then collected and utilized.

[0040] Pour an appropriate amount of the annealed sample into an agate mortar, add an appropriate amount of terpineol to the sample and grind it gently and fully to make it into a thick and suitable paste. Put a toothpick in the middle of the ceramic tube for fixation, then use tweezers to straighten the platinum wire on the ceramic tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com