Method for preparing battery-grade nickel sulfate by deeply removing sodium from refined nickel salt

A nickel sulfate, battery-grade technology, applied in the direction of nickel sulfate, etc., can solve problems such as difficult to control thoroughly, poor environment for extractant use, limited nickel extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

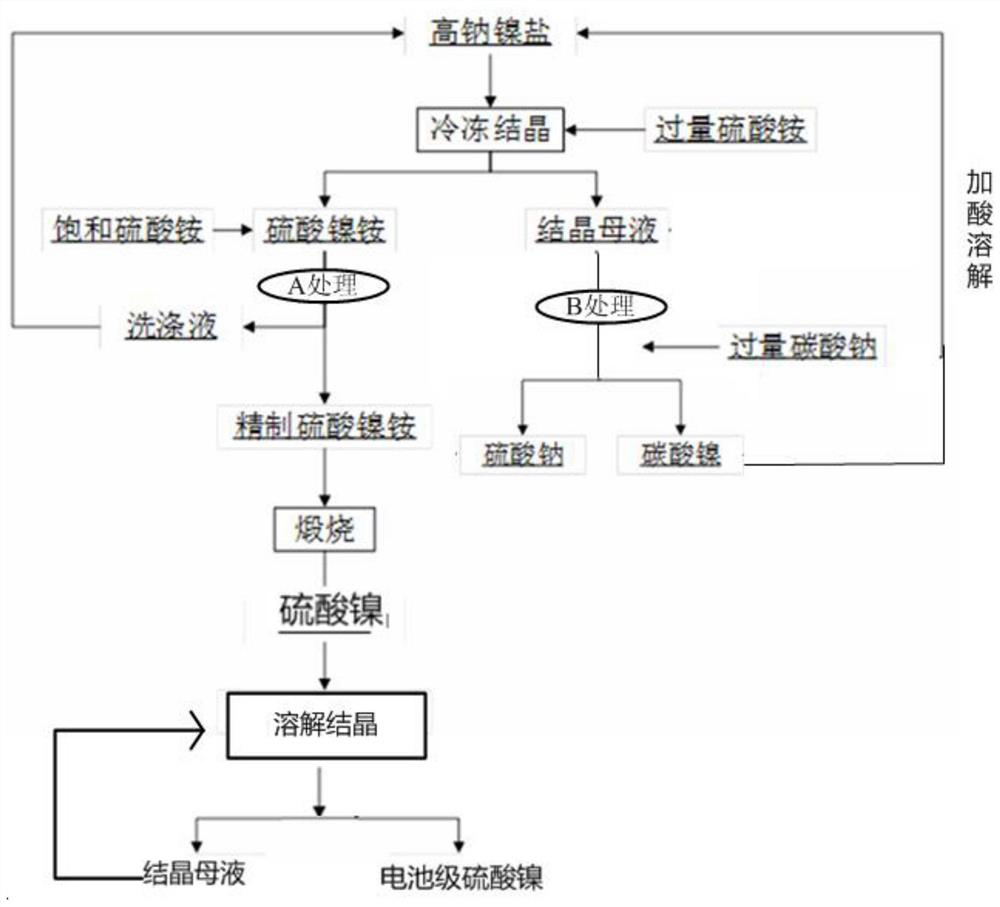

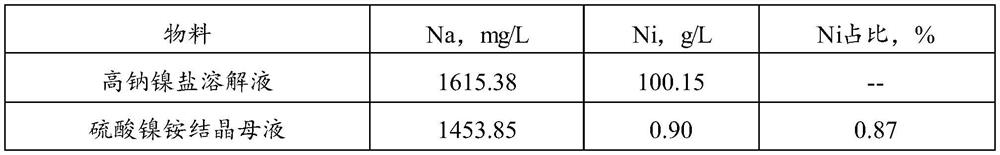

[0100] S1. Take 150kg of refined nickel sulfate, add 250L, and dissolve at 50°C to obtain a high-sodium nickel salt solution.

[0101] S2. Add 146L of ammonium sulfate solution with a concentration of 600g / L to the high-sodium nickel salt solution, stir for 10 minutes, put it in a refrigerator, and keep the temperature at -14°C for freezing and crystallization until Ni in the freezing solution<1g / L end at L. Afterwards, filter, obtain nickel ammonium sulfate crystal 243kg and nickel ammonium sulfate crystallization mother liquor.

[0102] S3. Perform A treatment on the obtained nickel ammonium sulfate crystals, and perform B treatment on the obtained crystallization mother liquor.

[0103] A treatment:

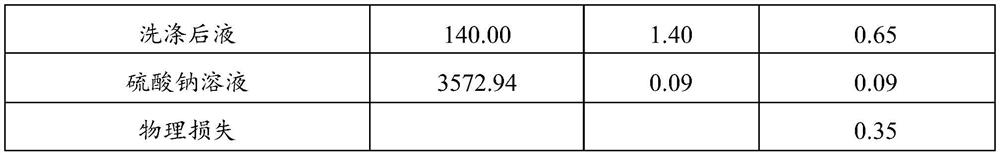

[0104] A1. Use saturated ammonium sulfate solution to wash nickel ammonium sulfate crystals three times, each time with 50L of washing liquid, and the temperature of the washing liquid is 3°C. After washing, 240 kg of refined ammonium nickel sulfate crystals were obtained, an...

Embodiment 2

[0122] S1. Take 154kg of refined nickel sulfate, add 250L, and dissolve at 65°C to obtain a high-sodium nickel salt solution.

[0123] S2. Add 160L of ammonium sulfate solution with a concentration of 600g / L to the high-sodium nickel salt solution, stir for 10 minutes, put it into a refrigerator, and keep the temperature at -10°C for freezing and crystallization until Ni in the freezing solution<1g / L end at L. Afterwards, filter, obtain nickel ammonium sulfate crystal 244kg and nickel ammonium sulfate crystallization mother liquor.

[0124] S3. Perform A treatment on the obtained nickel ammonium sulfate crystals, and perform B treatment on the obtained crystallization mother liquor.

[0125] A treatment:

[0126] A1. Use saturated ammonium sulfate solution to wash nickel ammonium sulfate crystals three times, each time with 50L of washing liquid, and the temperature of the washing liquid is 3°C. After washing, 242 kg of refined ammonium nickel sulfate crystals were obtained...

Embodiment 3

[0142] S1. Take 144kg of refined nickel sulfate, add 320L, and dissolve at 80°C to obtain a high-sodium nickel salt solution.

[0143] S2. Add 144L of ammonium sulfate solution with a concentration of 600g / L to the high-sodium nickel salt solution, stir for 10 minutes, put it in a refrigerator, and keep the temperature at -13°C for freezing and crystallization until Ni in the freezing solution<1g / L end at L. Afterwards, it was filtered to obtain 227.0 kg of ammonium nickel sulfate crystals and ammonium nickel sulfate crystal mother liquor.

[0144] S3. Perform A treatment on the obtained nickel ammonium sulfate crystals, and perform B treatment on the obtained crystallization mother liquor.

[0145] A treatment:

[0146] A1. The nickel ammonium sulfate crystals were washed three times with saturated ammonium sulfate solution, each time with 50 L of washing liquid, and the temperature of the washing liquid was 4°C. After washing, 226.5 kg of refined nickel ammonium sulfate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com