C/C composite material with high-temperature ceramic coating layer MTaO4 and preparation method thereof

A technology of high-temperature ceramics and composite materials, which is applied in the field of composite materials to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

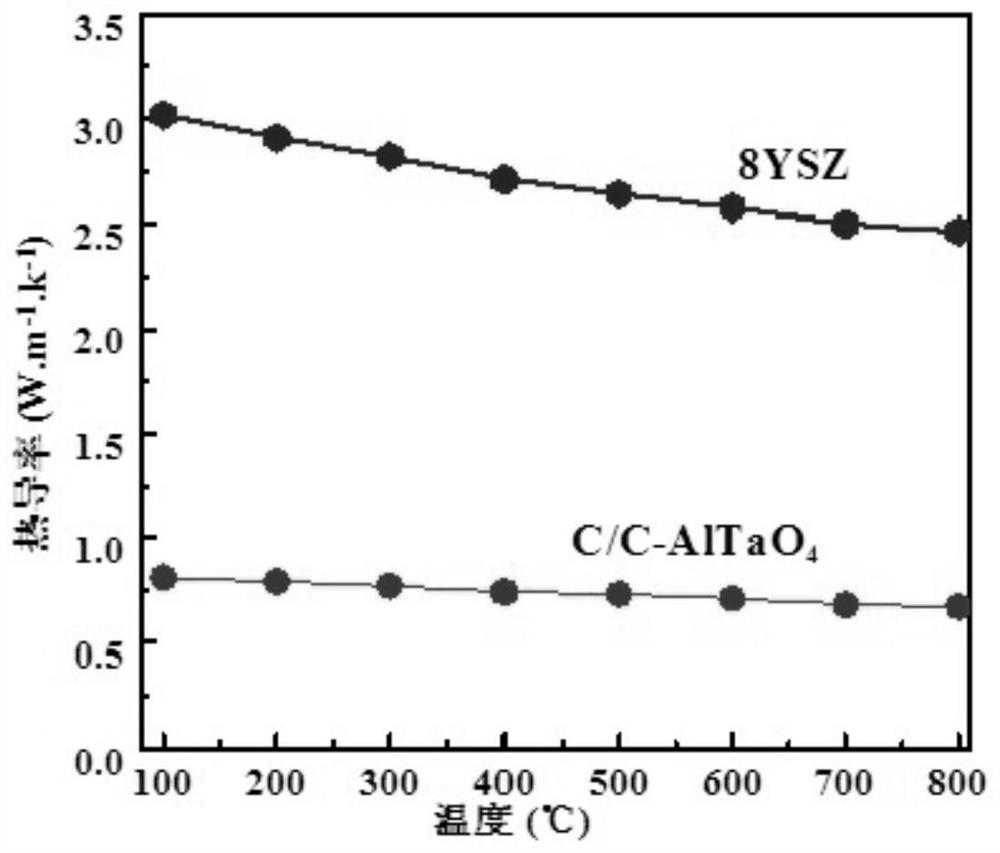

AI Technical Summary

Problems solved by technology

Method used

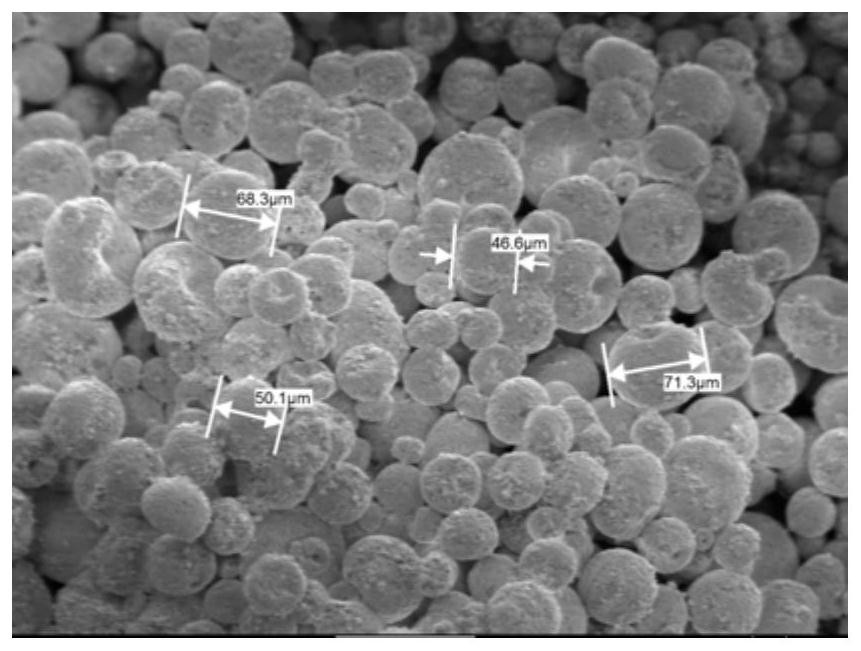

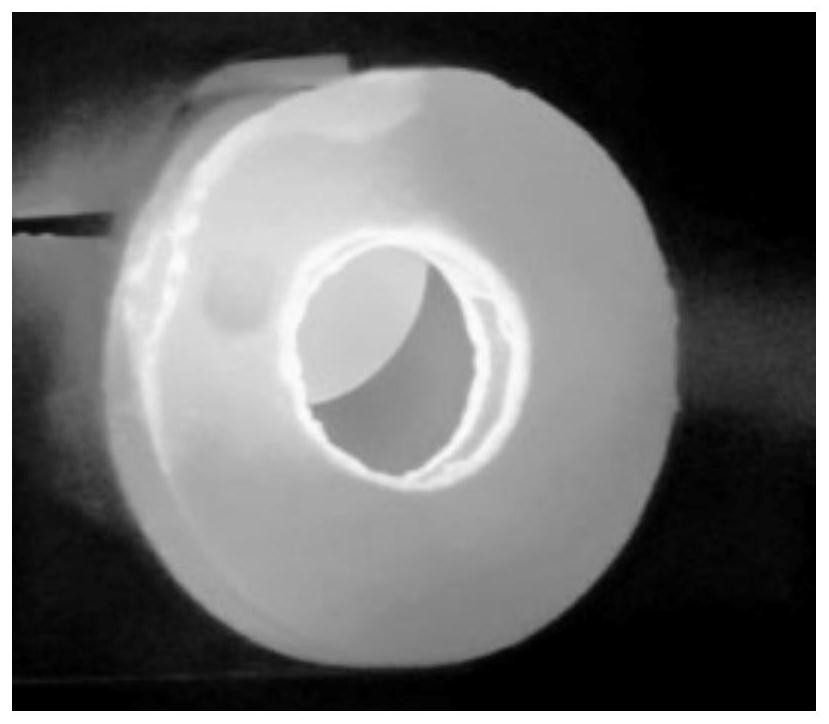

Image

Examples

Embodiment 1

[0033] C / C composite with high-temperature ceramic coating MTaO4, including a C / C composite matrix, outside which a transition layer and AlTaO are sequentially deposited 4 Ceramic coatings where the composition of the transition layer includes silicon, silicon carbide and aluminosilicates.

[0034] The preparation method of above-mentioned composite material, comprises the following steps:

[0035] Step 1: Weigh 121.4g of monocrystalline silicon, 25.4g of alumina powder and 11g of calcium oxide, place them together with absolute ethanol in a ball mill jar for mixing, seal and place on a planetary ball mill for ball milling, wherein the speed of the ball mill The ball milling time is 500r / min, and the ball milling time is 300min, so that the two powders are mixed evenly, and the mixed powder after ball milling is dried at 80°C for 24h, and passed through a 400-mesh sieve.

[0036]Step 2: Embed the C / C composite matrix in an alumina porcelain boat with the powder sieved in step...

Embodiment 2~9、 comparative example 1~4

[0042] The difference from Example 1 is that the process parameters in the preparation process are different, as shown in Table 1 for details.

[0043] Table 1 is the preparation process parameter table of embodiment 2~9 and comparative example 1~4

[0044] Monocrystalline silicon Aluminum oxide Calcium Oxide Calcination temperature (℃) Calcination time (h) Ceramic coating (μm) Example 2 121.4g 41g 11g 1300 10 200 Example 3 121.4g 21g 11g 1300 10 200 Example 4 121.4g 25.4g 24g 1300 10 200 Example 5 121.4g 25.4g 15g 1300 10 400 Example 6 121.4g 25.4g 11g 1100 15 300 Example 7 121.4g 25.4g 11g 1800 10 300 Example 8 121.4g 25.4g 11g 1300 10 200 Example 9 121.4g 25.4g 11g 1300 10 100 Comparative example 1 121.4g 25.4g 0 1300 10 400 Comparative example 2 121.4g 10g 5g 1300 10 300 Comparative example 3 121.4g 25.4g 11g 500 10 300 Comparati...

Embodiment 10

[0046] The difference from Example 1 is that the ceramic coating in this example is FeTaO 4 , where FeTaO 4 The preparation method of the powder is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com