A kind of intelligent slow-bonding prestressed steel strand and preparation method thereof

A slow-bonding prestressed and prestressed steel strand technology, which is applied in the engineering field, can solve the problems of poor high temperature aging resistance and lack of heat resistance stability, so as to improve high temperature aging resistance, durable mechanical properties, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

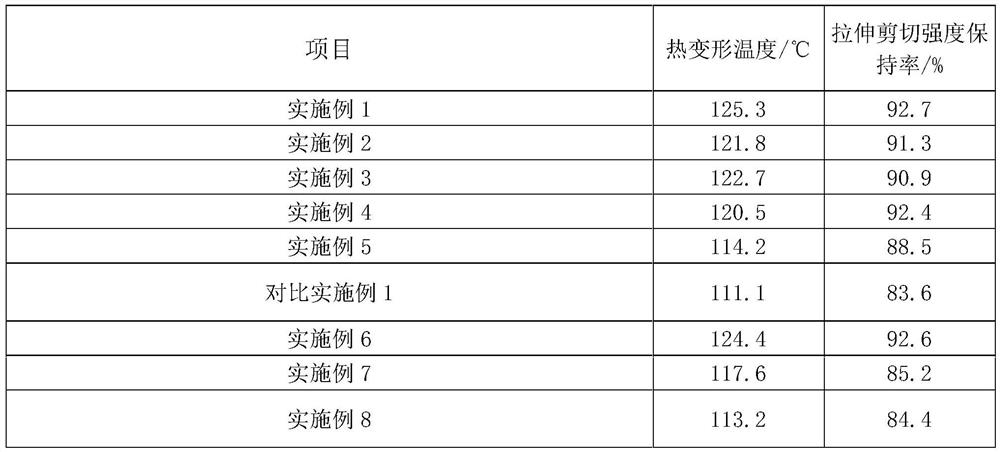

Examples

Embodiment 1

[0050] Preparation of Fluorinated Polyamides

[0051] 1. The tetrafluorosuccinic acid and tetraethylene pentamine whose molar ratio of carboxyl group and primary amino group is 1:1.2 are added to the reaction kettle of nitrogen atmosphere, pressurized to 0.3MPa, and stirred in 1.5h While heating up to 140°C, the pressure rose to 1.8MPa at this time, and the pressure was kept constant by intermittently removing the generated water vapor and the temperature in the kettle was kept at 150°C for 2h;

[0052] 2. Release the pressure of the reaction kettle to normal pressure, and react at a constant temperature of 140 °C; then evacuate to -0.08MPa, and perform a constant temperature reaction at 140 °C. Finally, pressurize the reaction kettle to normal pressure and cool down to 60 °C, and continue to stir and react at a constant temperature for 1 hour. ;

[0053] 3. Cool the reaction kettle to 23°C, stop stirring, and discharge to obtain fluorine-containing polyamide.

[0054] Pr...

Embodiment 2

[0062] The rest are the same as in Example 1, except that in the preparation process of the slow-bonding adhesive, the curing agent consists of 13.64 parts of fluorinated polyamide prepared, 13.64 parts of 650 low molecular weight polyamide, 2.72 parts of carboxyl-functionalized organic polyamide Silicon compound.

Embodiment 3

[0064] The rest is the same as in Example 1, except that in the preparation process of the slow-bonding adhesive, the curing agent consists of 21.43 parts of fluorine-containing polyamide prepared, 7.14 parts of 650 low molecular weight polyamide, 1.43 parts of carboxyl-functionalized organic polyamide Silicon compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com