A kind of sealant used in lining sliding sleeve sealing system and preparation method thereof

A sealing system and sealant technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor sealing effect, unstable coating adhesion, high temperature flow, etc. Production efficiency and product stability, improving compatibility, ensuring the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A sealant used in a liner sliding sleeve sealing system, including A component and B component, the mass percentage of each raw material component:

[0042] A component:

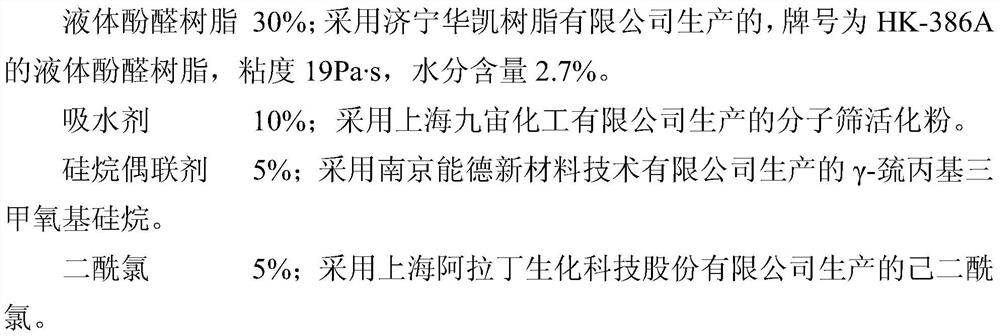

[0043]

[0044]

[0045] Component B:

[0046]

[0047] The preparation method of the sealant:

[0048] Preparation method of component A:

[0049] 1. Add the phenolic resin and water absorbing agent to the reaction kettle and stir for 1 hour.

[0050] 2. Slowly drop the silane coupling agent and 50% by mass of diacid chloride into the reaction kettle, dropwise for 1 hour, and continue to stir for 0.5 hour after the dropwise addition is completed.

[0051] 3. Add the liquid polysulfide rubber into the reaction kettle and stir for 0.5 hours.

[0052] 4. The remaining diacid chloride was slowly added dropwise into the reaction kettle, the dropwise addition time was 1 hour, and the stirring was continued for 0.5 hour after the dropwise addition was completed.

[0053] 5. Add the thixotropic...

Embodiment 2

[0058] A sealant used in a lining sliding sleeve sealing system, including A component and B component, the mass percentage of each raw material component:

[0059] A component:

[0060]

[0061] Component B:

[0062]

[0063] The preparation method of component A and component B and the sealant is the same as that in Example 1.

Embodiment 3

[0065] A sealant used in the lining sliding sleeve sealing system, including A component and B component, the mass percentage of each raw material component:

[0066] A component:

[0067]

[0068]

[0069] B component:

[0070] Basic metal oxide 20%; With embodiment 1

[0071] Catalyst 10%; With embodiment 1

[0072] Epoxy diluent 40%; With embodiment 1

[0073] Thixotropic agent 2%; With embodiment 1

[0074] Thickening filler 28%; With embodiment 1;

[0075] The preparation method of component A and component B and the sealant is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com