Pure electric direct-drive rotary drilling rig

A rotary drilling rig and direct drive technology, which is applied to rotary drilling rigs, rotary drilling, drill pipes, etc., can solve the problems of reducing power transmission paths, high diesel engine emission levels, and high energy consumption, reducing maintenance content, The effect of improving diversity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment (accompanying drawing).

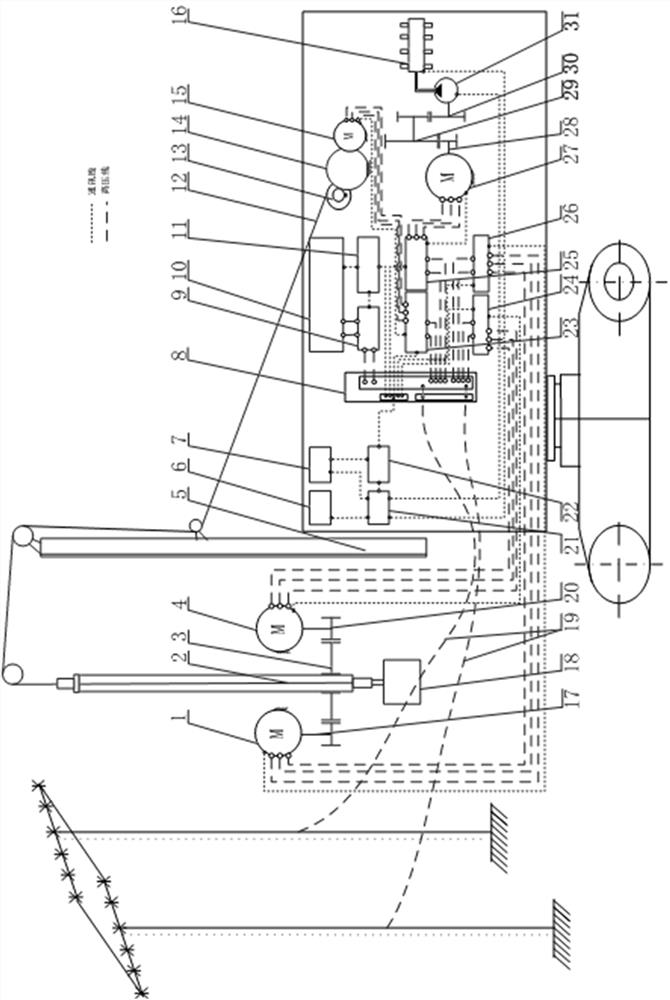

[0024] Such as figure 1 As shown, the pure electric direct-drive rotary drilling rig of the present invention includes a high-voltage power supply system, a control signal communication system, and a mechanical power transmission system; , the battery management system 11 connected to the corresponding ports of the high-voltage power distribution box 9, the rectification device 8, and the power storage battery system 10, and the external cable 19 connected to the corresponding interface of the rectification device 8 for coupling output of electric energy; The rectification device 8 is output in the form of DC high voltage, respectively connected to the power head motor I controller 26, the power head motor II controller 24, the main pump motor controller 25 and the main winch motor controller 23, and the DC high voltage The electricity is converted into three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com