Preparation method of biological 3D printing composite ink for repairing cartilage defects

A 3D printing and cartilage technology, applied in the field of biological 3D printing, can solve the problems of natural three-dimensional microenvironment that cannot simulate cell growth, cell adhesion, unsatisfactory directional differentiation, and difficulty in accurate imitation, and achieve good clinical application prospects and value, rapid cross-linking and curing, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1. The present invention provides a technical solution: a method for preparing a bio-3D printing composite ink for repairing cartilage defects, comprising the following steps:

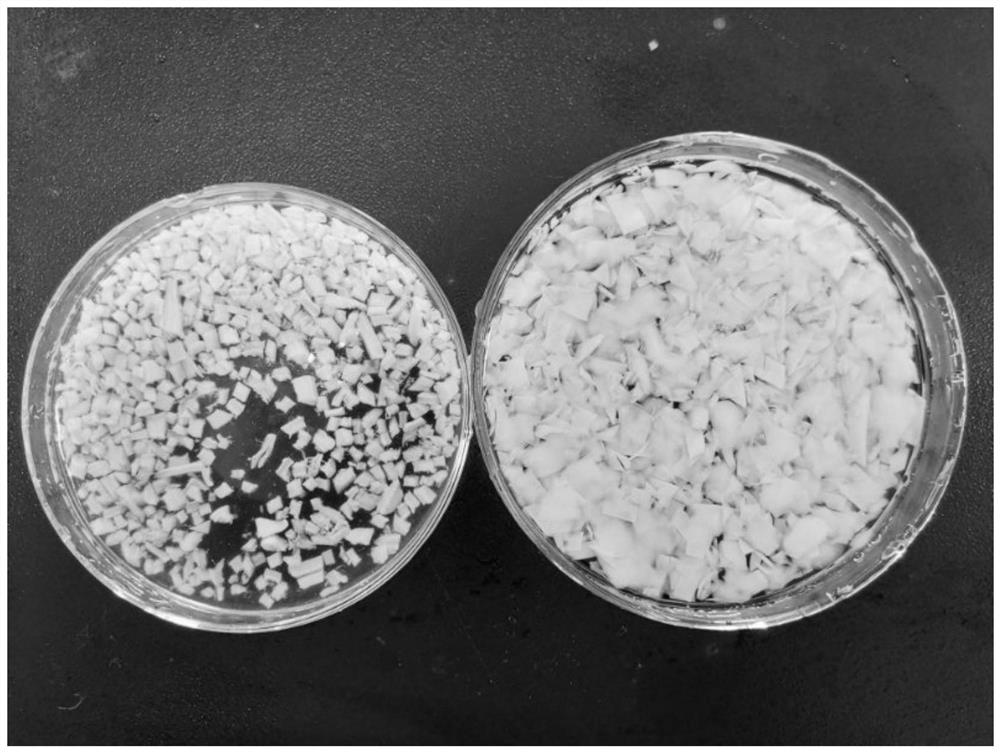

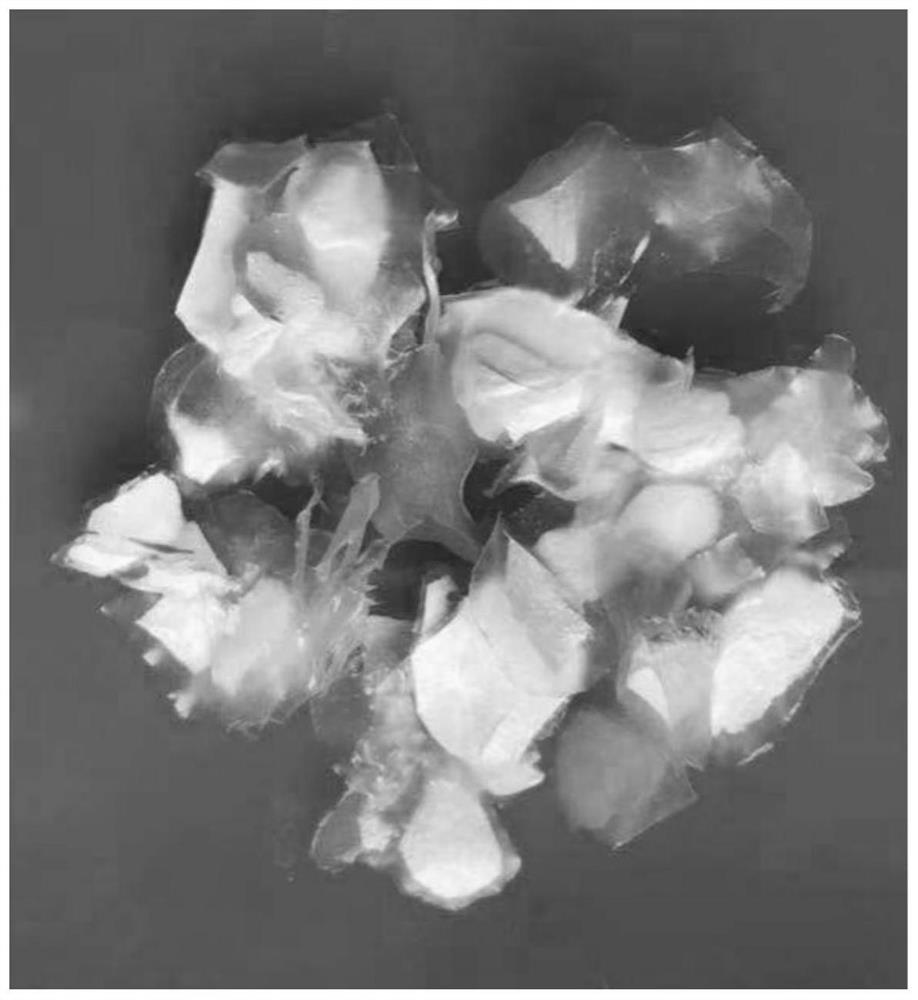

[0033] S1. Preparation of cartilage granules: take the fresh articular surface hyaline cartilage or costal cartilage of animals, cut off the hyaline cartilage from the articular surface with a sharp scalpel blade to obtain cartilage slices, and then cut the cartilage slices into granules with a particle size of 1-2mm 3 (Such as figure 1 shown);

[0034] S2. Decellularization treatment: Soak cartilage particles in hypotonic Tris-HCl buffer, the concentration of hypotonic Tris-HCl buffer is 10mM, PH=8, and then cycle freeze-thaw at -80°C ~ 37°C 6 cycles; then digest with 0.25% trypsin at 37°C for 24 hours, and replace the trypsin solution every 4 hours; then wash away the trypsin with hypertonic Tris-HCl buffer solution, The permeated Tris-HCl buffer solution is composed of NaCl 1.5M...

Embodiment 2

[0041] Embodiment 2. The present invention provides a technical solution: a method for preparing a bio-3D printing composite ink for repairing cartilage defects, comprising the following steps:

[0042] S1. Preparation of cartilage granules: take the fresh articular surface hyaline cartilage or costal cartilage of animals, cut off the hyaline cartilage from the articular surface with a sharp scalpel blade to obtain cartilage slices, and then cut the cartilage slices into granules with a particle size of 1-2mm 3 (Such as figure 1 shown);

[0043] S2. Decellularization treatment: Soak cartilage particles in hypotonic Tris-HCl buffer, the concentration of hypotonic Tris-HCl buffer is 10mM, PH=8, and then cycle freeze-thaw at -80°C ~ 37°C 6 cycles; then digest with 0.25% trypsin at 37°C for 24 hours, and replace the trypsin solution every 4 hours; then wash away the trypsin with hypertonic Tris-HCl buffer solution, The permeated Tris-HCl buffer solution is composed of NaCl 1.5M...

Embodiment 3

[0050] Embodiment 3. The present invention provides a technical solution: a method for preparing a bio-3D printing composite ink for repairing cartilage defects, comprising the following steps:

[0051] S1. Preparation of cartilage granules: take the fresh articular surface hyaline cartilage or costal cartilage of animals, cut off the hyaline cartilage from the articular surface with a sharp scalpel blade to obtain cartilage slices, and then cut the cartilage slices into granules with a particle size of 1-2mm 3 (Such as figure 1 shown);

[0052] S2. Decellularization treatment: Soak cartilage particles in hypotonic Tris-HCl buffer, the concentration of hypotonic Tris-HCl buffer is 10mM, PH=8, and then cycle freeze-thaw at -80°C ~ 37°C 6 cycles; then digest with 0.25% trypsin at 37°C for 24 hours, and replace the trypsin solution every 4 hours; then wash away the trypsin with hypertonic Tris-HCl buffer solution, The permeated Tris-HCl buffer solution is composed of NaCl 1.5M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com