Composite polyacrylamide flocculant and application thereof

A polyacrylamide and flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc., can solve the problem of low solid content in the sedimentation part, poor flocculation effect, inability to effectively perform double layer compression and charge neutralization Function and other issues, to achieve the effect of enhancing the flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A composite polyacrylamide flocculant, composed of 80 parts of anionic polyacrylamide, 10 parts of nonionic polyacrylamide, 9 parts of magnesium sulfate crystals and 1 part of calcium chloride particles; specifically, the anionic polyacrylamide Put 80 parts of crystalline powder, 10 parts of nonionic polyacrylamide, 9 parts of magnesium sulfate crystals and 1 part of calcium chloride granules into a blender, stir and mix at room temperature for 50 minutes, and then pack for use.

Embodiment 2

[0022] A composite polyacrylamide flocculant, composed of 40 parts of anionic polyacrylamide, 40 parts of nonionic polyacrylamide, 9 parts of magnesium chloride crystals and 1 part of zinc chloride particles; specifically, 40 parts of anionic polyacrylamide 40 parts, 40 parts of nonionic polyacrylamide, 9 parts of magnesium chloride crystals and 1 part of zinc chloride particles were put into a blender, stirred and mixed at room temperature for 50 minutes, and then packaged for use.

Embodiment 3

[0024] A composite polyacrylamide flocculant, which is compounded by 80 parts of anionic polyacrylamide, 20 parts of magnesium sulfate crystals and 10 parts of ammonium sulfate; the specific steps are as follows: Specifically, 80 parts of anionic polyacrylamide and magnesium sulfate crystals 20 parts and 10 parts of ammonium sulfate were put into a blender, stirred and mixed at room temperature for 50 minutes, and then packaged for use.

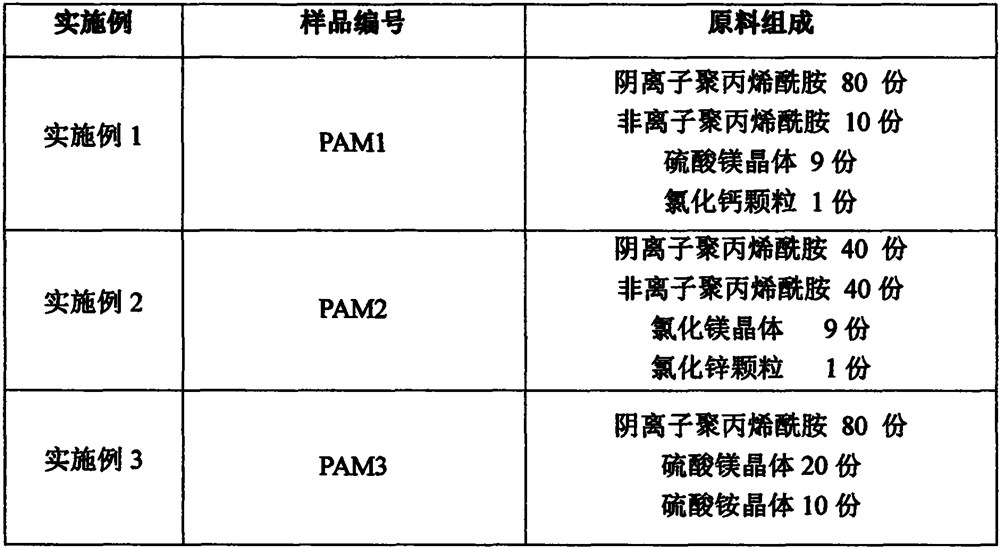

[0025] According to the raw material composition of the composite polyacrylamide flocculant in Examples 1 to 3, see Table 1.

[0026] Table 1 Raw material composition of composite polyacrylamide flocculant

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com