MXene composite foam constructed based on polyurethane foaming principle and preparation method of MXene composite foam

A composite foam and polyurethane technology, which is applied in the field of preparation of new low-dimensional materials, can solve the problems of complex airgel technology and the inability to obtain large-size and high-quality airgel, and achieve excellent mechanical properties, enhanced stability, and shape avoidance collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

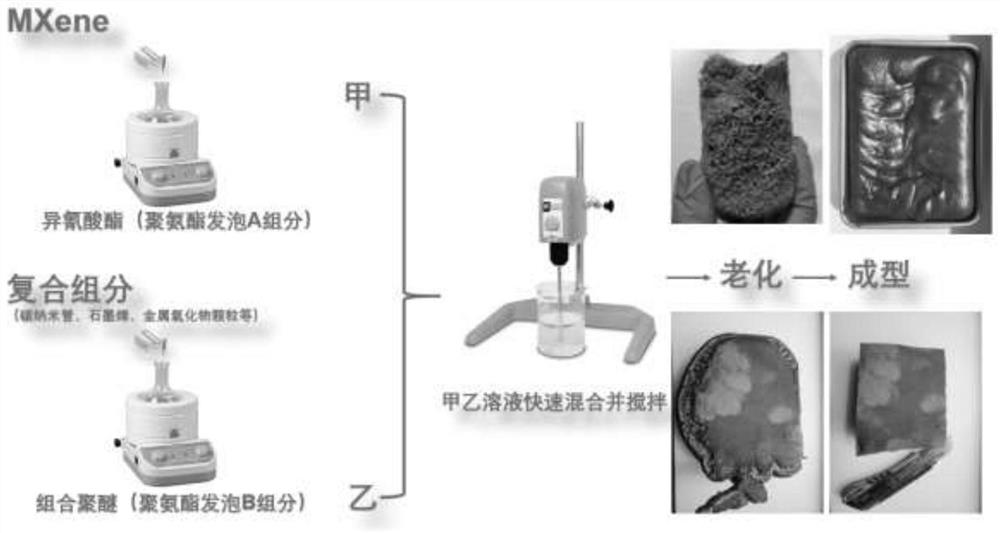

[0033] A kind of preparation method that builds MXene composite foam based on polyurethane foaming principle, such as figure 1 As shown, the method specifically includes the following steps:

[0034] Step 1: Mix two-dimensional transition metal carbonitride MXenes and isocyanate evenly to obtain a solution;

[0035] The two-dimensional transition metal carbonitride MXenes is preferably Ti 3 C 2 T x 、Ti 2 N, Ti 2 CT x 、Ti 3 CN, V 4 C 3 , V 2 C. Nb 4 C 3 、Mo 2 TiC, Mo 2 C. Ta 4 C 3 or Ta 2 C; the isocyanate is preferably phenylene diisocyanate (TDI), isophorone diisocyanate (IPDI), diphenylmethane diisocyanate (MDI), dicyclohexylmethane diisocyanate (HMDI), hexamethylene diisocyanate (HMDI), Isocyanate (HDI) or lysine diisocyanate (LDI); The mass g of the two-dimensional transition metal carbonitride MXenes: the volume mL of isocyanate is preferably (0.5-20): (2-400); Mix uniformly by stirring, and the stirring method can be used: 1. After the configuration, th...

Embodiment 1

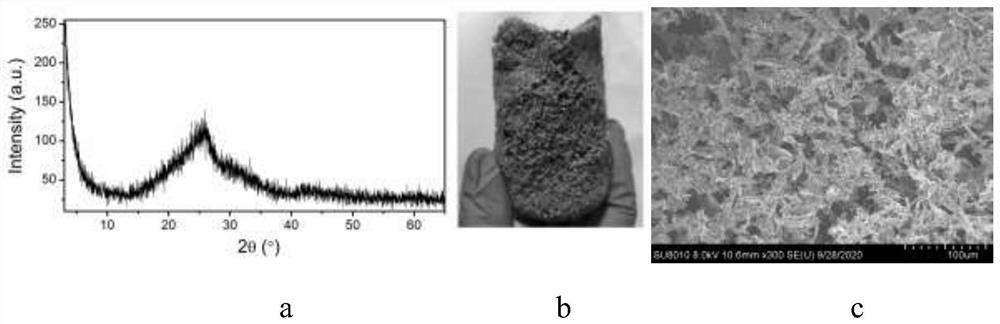

[0043] Ti 3 C 2 T x The preparation of MXene and carbon nanotube composite foam, the method comprises the steps:

[0044] (1) Take Ti 3 C 2 T x MXene few-layer powder 0.5g and phenylene diisocyanate (TDI) (polyurethane foam A component) 2mL; using a glass rod, manually stirred for 10 minutes to obtain a solution;

[0045] (2) Mix 0.5 g of carbon nanotubes with 2 mL of propylene glycol block polyether (component B of polyurethane foam), stir at a constant speed for 10 minutes with a glass stirring rod, and the ambient temperature is 25° C. to obtain solution B;

[0046] (3) Put the two solutions of A and B obtained in step (1) and (2) into the mixing tank at the same time according to the ratio of 1:1, and stir quickly with a glass stirring rod. After 5 minutes, a colloid with certain fluidity is formed. solution.

[0047] (4) Quickly transfer the colloidal solution obtained in step (3) to a glass beaker at an ambient temperature of 35 degrees Celsius, stand still for ...

Embodiment 2

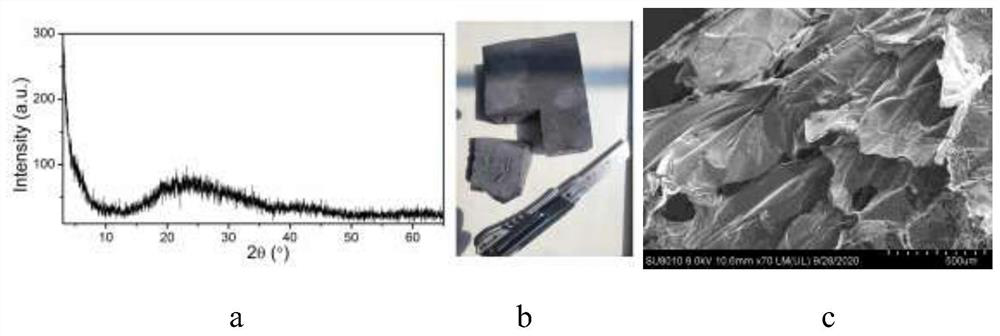

[0052] Ti 2 CT x The preparation of MXene and graphene composite foam, the method comprises the steps:

[0053] (1) Take Ti 2 CT x MXene few-layer powder 5g; and isophorone diisocyanate (IPDI) (polyurethane foaming component A) 50mL; use a glass rod, mechanically stir for 60 minutes, the ambient temperature is 25 ° C, to obtain a solution;

[0054] (2) Mix 4 g of graphene with 40 mL of propylene glycol block polyether (polyurethane foaming component B), and stir it mechanically for 10 minutes at an ambient temperature of 25° C. to obtain solution B;

[0055] (3) Put the two solutions of A and B obtained in step (1) and (2) into the mixing tank at the same time according to the ratio of 1:1, and stir quickly with a glass stirring rod. After 10 minutes, a colloid with certain fluidity is formed. solution.

[0056] (4) Quickly transfer the colloidal solution obtained in step (3) to a vacuum barrel at an ambient temperature of 35 degrees Celsius, fill the metal mold, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com