Kettle-type synthesis method of polylactic acid with high melt index and modified polylactic acid prepared thereby

A high melt index, synthesis method technology, applied in the field of modified polylactic acid, can solve the problems of high modification temperature, low melt index, limited screw length, etc., achieve low energy consumption, stable melt index, small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

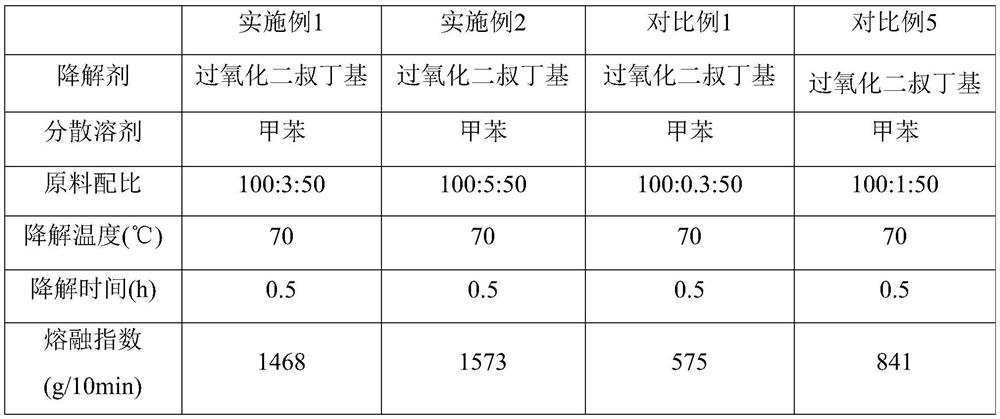

Embodiment 1

[0028] A kind of kettle formula synthetic method of high melt index polylactic acid, comprises the following steps:

[0029] (1) 100 parts by weight of polylactic acid particles with a melt index of 10g / 10min (230°C, 2160g) and 3 parts by weight of di-tert-butyl peroxide degradation agent are added to the stirring and heating In the high-temperature reactor, adding parts by weight is 50 parts of toluene as a dispersion solvent;

[0030] (2) Heat the reaction kettle to 70°C, start stirring, adjust the rotation speed to 800rpm, keep stirring for 0.5h and then cool down to prepare the mixture;

[0031] (3) Filter the mixture in the reaction kettle to complete solid-liquid separation, and dry the solid matter at 80° C. for 12 hours to obtain modified polylactic acid.

Embodiment 2

[0033] A kind of kettle formula synthetic method of high melt index polylactic acid, comprises the following steps:

[0034] (1) 100 parts by weight of polylactic acid particles with a melt index of 10g / 10min (230°C, 2160g) and 5 parts by weight of di-tert-butyl peroxide degradation agent are added to a high temperature with stirring and heating In the reactor, adding parts by weight is 50 parts of toluene as a dispersion solvent;

[0035] (2) Heat the reaction kettle to 70°C, start stirring, adjust the rotation speed to 800rpm, keep stirring for 0.5h and then cool down to prepare the mixture;

[0036] (3) Filter the mixture in the reaction kettle to complete solid-liquid separation, and dry the solid matter at 80° C. for 12 hours to obtain modified polylactic acid.

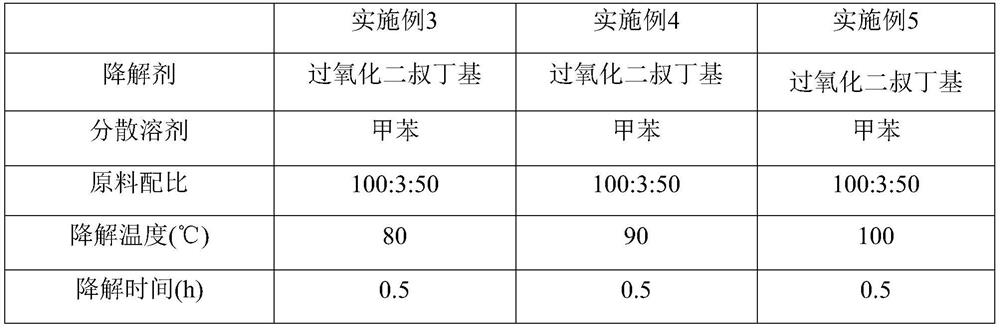

Embodiment 3

[0038] A kind of kettle formula synthetic method of high melt index polylactic acid, comprises the following steps:

[0039] (1) 100 parts by weight of polylactic acid particles with a melt index of 10g / 10min (230°C, 2160g) and 3 parts by weight of di-tert-butyl peroxide degradation agent are added to a high temperature with stirring and heating In the reactor, adding parts by weight is 50 parts of toluene as a dispersion solvent;

[0040] (2) Heat the reaction kettle to 80°C, start stirring, adjust the rotating speed to 800rpm, keep stirring for 0.5h and then cool down to prepare the mixture;

[0041] (3) Filter the mixture in the reaction kettle to complete solid-liquid separation, and dry the solid matter at 80° C. for 12 hours to obtain modified polylactic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com