Foaming master batch for plastic floating plate for ecological restoration of water body and preparation method

A technology of ecological restoration and foaming masterbatch, applied in the field of photocatalytic treatment of sewage, can solve the problems of difficult separation, easy loss, difficult recovery, etc., and achieve the effect of improving adsorption, overcoming easy loss and excellent adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

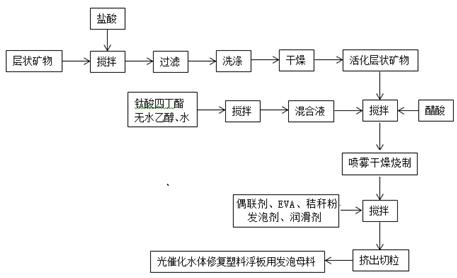

Method used

Image

Examples

Embodiment 1

[0029] (1) Grind and pulverize the layered mineral talc powder first, then add it to hydrochloric acid with a mass fraction of 10%, stir at a speed of 200rpm to make a suspension slurry, continue to stir and react at room temperature for 6h, filter, and use deionized Washed twice with water, then dried at 80°C to obtain activated layered minerals;

[0030] (2) Mix tetrabutyl titanate, absolute ethanol, and water with a mass ratio of 15:65:30 by stirring to form a mixed solution, and then add the activated layered minerals obtained in step (1) in an amount of mixing 15% of the mass of the solution to disperse the activated layered minerals to form a slurry, then stir at a speed of 900rpm, and slowly drop in the acetic acid solution. The time for adding acetic acid is controlled at 20 minutes, and the amount of acetic acid added is controlled at the pH value of the slurry. 5.5; then spray drying at 200°C, and firing at 400°C for 10 minutes, the formed titanium dioxide forms a ti...

Embodiment 2

[0033] (1) Grind and pulverize the layered mineral serpentine powder first, then add it to hydrochloric acid with a mass fraction of 10%, stir at a speed of 300rpm to make a suspension slurry, continue to stir and react at room temperature for 12 hours, filter, and use Washed with ion water for 4 times, then dried at 80°C to obtain activated layered minerals;

[0034] (2) Mix tetrabutyl titanate, absolute ethanol, and water with a mass ratio of 15:65:30 by stirring to form a mixed solution, and then add the activated layered minerals obtained in step (1) in an amount of mixing 15% of the mass of the solution to disperse the activated layered minerals to form a slurry, then stir at a speed of 1200rpm, and slowly drop in the acetic acid solution, the time for adding acetic acid is controlled at 30min, and the amount of acetic acid added is controlled at the pH value of the slurry 6; Then spray dry at 200°C, and fire at 400°C for 10 minutes, the formed titanium dioxide forms a ti...

Embodiment 3

[0037] (1) Grind and pulverize the layered mineral mica powder first, then add it to hydrochloric acid with a mass fraction of 10%, stir at a speed of 300rpm to make a suspension slurry, continue to stir and react at room temperature for 24h, filter, and use deionized Washed with water for 4 times, then dried at 80°C to obtain activated layered minerals;

[0038] (2) Mix tetrabutyl titanate, absolute ethanol, and water with a mass ratio of 15:65:30 by stirring to form a mixed solution, and then add the activated layered minerals obtained in step (1) in an amount of mixing 15% of the mass of the solution to disperse the activated layered minerals to form a slurry, then stir at a speed of 1200rpm, and slowly drop in the acetic acid solution, the time for adding acetic acid is controlled at 30min, and the amount of acetic acid added is controlled at the pH value of the slurry 5.5; then spray drying at 200°C, and firing at 400°C for 10 minutes, the formed titanium dioxide forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com