A kind of anti-explosion and impact-resistant polyurea coating for aluminum foam and preparation method thereof

A technology of aluminum foam and impact resistance, which is applied in the field of preparation of functional coating materials, can solve the problems of weak interfacial bonding force, poor energy absorption effect, and large difference between soft and hard of polyurea coating materials, and achieve good impact resistance, Improve interface bonding force and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

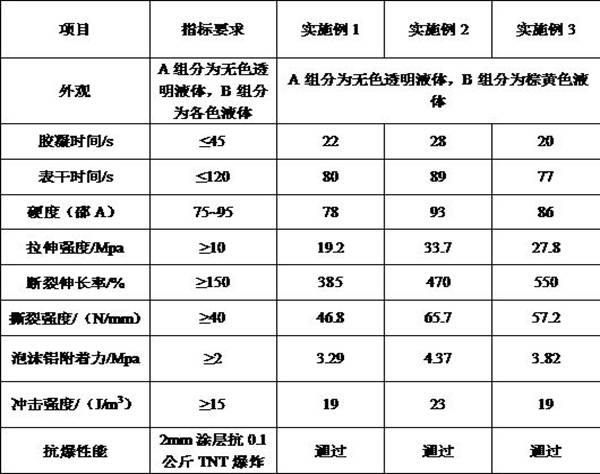

Examples

Embodiment 1

[0027] This example provides an anti-explosion and impact-resistant polyurea coating material for foamed aluminum. The preparation raw materials and proportions are: A component by mass percentage, Wanhua isocyanate MDI-50 51 parts, Haian Petrochemical Co., Ltd. Polyoxypropylene glycol PPG-2000 46 parts, Qilu Petrochemical alkylene carbonate 3 parts; component B by mass percentage, amino-terminated polyether Jeffamine D-2000 60 parts, amino-terminated polyether Jeffamine T-5000 5 parts , Wanhua 3,5-diethyltoluenediamine E100 22 parts, Wanhua 4,4,-bis-sec-butylaminodiphenylmethane W6200 9 parts, leveling agent BYK-354 1 part, defoamer BYK- 0.8 part of 066N, 1 part of wetting and dispersing agent BYK-164, 0.7 part of Dow Corning coupling agent KH-550, 0.5 part of BASF antioxidant 1135.

[0028] The preparation method of the polyurea coating material used in this embodiment is as follows:

[0029] (1) Add polyoxypropylene glycol PPG-2000 to the reactor in parts by mass, dehydrat...

Embodiment 2

[0033] This example provides an anti-explosion and impact-resistant polyurea coating material for foamed aluminum. The preparation raw materials and proportions are: A component by mass percentage, Wanhua isocyanate MDI-50 50 parts, Mitsubishi polyurea Tetrahydrofuran diol PTMG-100045 parts, Qilu Petrochemical alkylene carbonate 5 parts; B component by mass percentage, amino-terminated polyether Jeffamine D-200058 parts, amino-terminated polyether Jeffamine T-5000 5 parts, Wanhua 3 , 20 parts of 5-diethyltoluenediamine E100, 13 parts of Wanhua 4,4,-bis-sec-butylaminodiphenylmethane W6200, 1 part of leveling agent BYK-354, 0.8 parts of defoamer BYK-066N, Wetting and dispersing agent BYK-164 1 part, Dow Corning coupling agent KH-550 0.7 part, BASF antioxidant 1135 0.5 part.

[0034]The preparation method of the polyurea coating material used in this embodiment is as follows:

[0035] (1) Add polytetrahydrofuran glycol PTMG-1000 to the reaction kettle in parts by mass, dehydrate...

Embodiment 3

[0039] This example provides an anti-explosion and impact-resistant polyurea coating material for foamed aluminum. The preparation raw materials and proportions are: A component by mass percentage, Wanhua isocyanate MDI-50 47 parts, Bayer polyurea Ether polyol Acclaim 420050 parts, Qilu Petrochemical alkylene carbonate 3 parts; B component by mass percentage, amino-terminated polyether Jeffamine D-200053 parts, amino-terminated polyether Jeffamine T-5000 6 parts, Wanhua 3, 17 parts of 5-diethyltoluenediamine E100, 20 parts of Wanhua 4,4,-bis-sec-butylaminodiphenylmethane W6200, 1 part of leveling agent BYK-354, 0.8 parts of defoamer BYK-066N, moisturizing Wet dispersant BYK-164 1 part, Dow Corning coupling agent KH-550 0.7 part, BASF antioxidant 1135 0.5 part.

[0040] The preparation method of the polyurea coating material used in this embodiment is as follows:

[0041] (1) Add polyether polyol Acclaim 4200 to the reaction kettle in parts by mass, dehydrate under reduced pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com