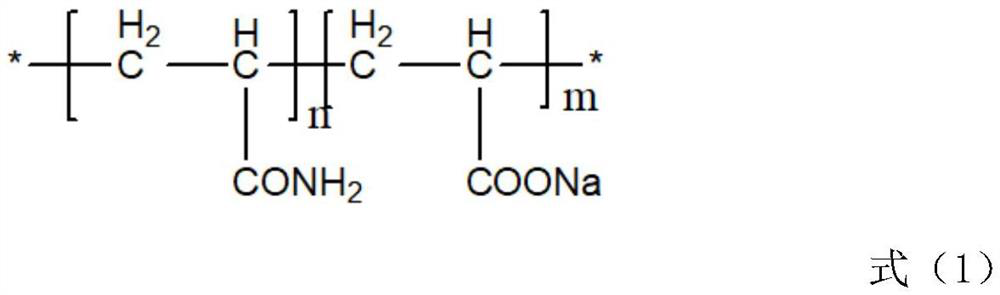

Acrylic acid-acrylamide copolymerization combined expansion material for self-tackifying particles and preparation method of self-tackifying particles

A technology of acrylamide copolymer and acrylamide copolymer is applied in the field of preparation of support particles for filling sand control and fracturing stimulation, and can solve problems such as unfavorable flowback, consumption, large pump power and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

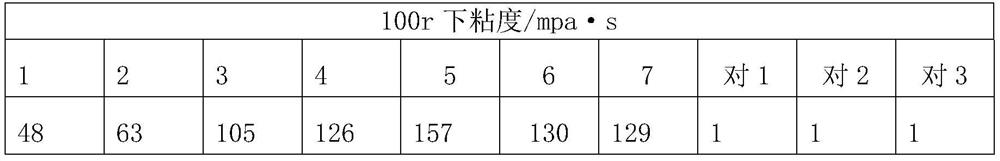

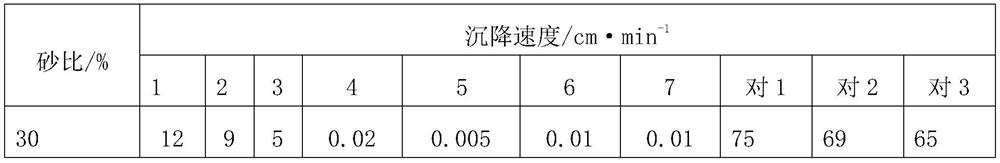

Examples

Embodiment 1

[0035] 1) Take 1000g of quartz sand as raw material, heat to 160°C, add 10g of epoxy resin E12 (604), and stir evenly;

[0036] 2) The temperature of the mixture in step 1) was lowered to 140°C, and 13g of anionic polyacrylamide (commercially available, about 40 mesh) particles were added, and stirred evenly;

[0037] 3) Add 1.95g of phenalkamine T-31 curing agent, stir evenly and add 0.5g of calcium stearate;

[0038] 4) After cooling, sieve.

[0039] The particle size obtained after sieving is 20-40 mesh, and the surface is coated or partially coated with polyacrylamide particles.

Embodiment 2

[0041] 1) Take 1000g of quartz sand as raw material, heat to 160°C, add 10g of epoxy resin E12 (604), and stir evenly;

[0042] 2) The temperature of the mixture in step 1) was lowered to 140°C, and 13g of anionic polyacrylamide (commercially available, below 80 mesh) particles were added, and stirred evenly;

[0043] 3) Add 1.95g of alicyclic amine curing agent TCY-450 (Henan Tianze Industrial Co., Ltd.), stir evenly and add 0.5g of calcium stearate;

[0044] 4) After cooling, sieve.

Embodiment 3

[0046] 1) Select 13g of anionic polyacrylamide with a molecular weight of 22 million and a degree of hydrolysis of 25%, dissolve it in 200ml of water, add 0.2g of urea, 0.1g of thiourea and 0.001g of OP-10, stir well, and dry at 102 degrees Celsius. Crush to below 80 mesh;

[0047] 2) Take 1000g of quartz sand as raw material, heat to 160°C, add 10g of epoxy resin E12 (604), and stir evenly;

[0048] 3) The temperature of the mixture in step 2) is lowered to 140° C., adding the expanded composite particles in step 1), and stirring evenly;

[0049] 4) Add 1.95g of alicyclic amine curing agent TCY-450 (Henan Tianze Industrial Co., Ltd.), stir evenly and add 0.5g of calcium stearate;

[0050] 5) After cooling, sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com