Method for preparing bio-oil by coupling biomass pyrolysis and methane aromatization

A biomass pyrolysis and aromatization technology, applied in the energy field, can solve the problems of high reaction conditions, restricted application, and high cost of hydrogen production, so as to reduce costs and achieve the effect of yield and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

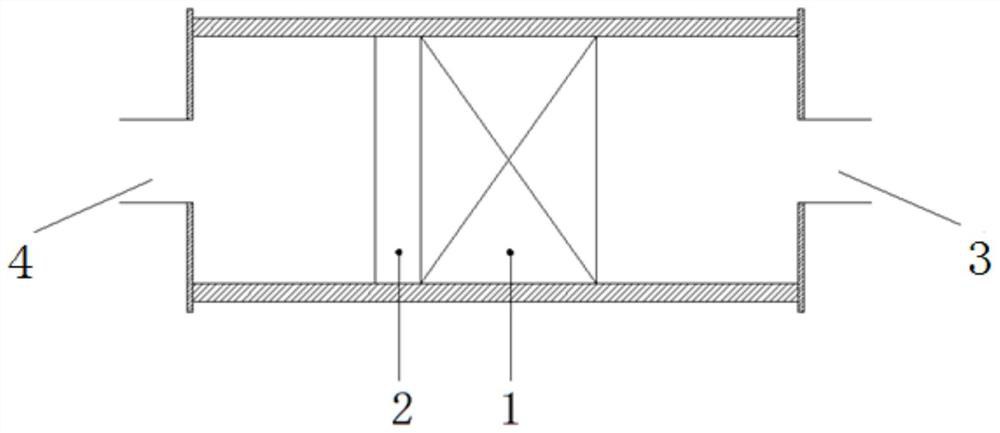

Image

Examples

Embodiment 1

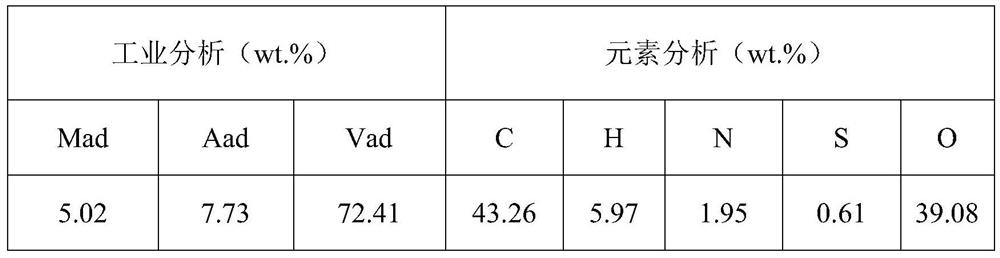

[0039] The biomass used in this example is corn stalks, and its industrial analysis and elemental analysis are shown in Table 1.

[0040] Table 1

[0041]

[0042] 1. Preparation of Mo / HZSM-5 catalyst

[0043] Immerse the ammonium molybdate solution on the HZSM-5 powder, immerse at room temperature for 18 hours, dry at 90°C for 10 hours, calcinate at 550°C for 6 hours, press into tablets, and screen out 20-40 mesh particles to obtain Mo / HZSM-5 catalyst.

[0044] 2. Preparation of bio-oil by catalytic pyrolysis

[0045] (1) crush the corn stalks and pass through a 100-mesh sieve, and then mix the two according to the mass ratio of Mo / HZSM-5 catalyst: corn stalks=5:1 to obtain a mixture;

[0046](2) The mixture is placed in a fixed-bed pyrolysis reactor, and methane gas is introduced from the inlet of the pyrolysis reactor at a gas flow rate of 60ml / min, and the catalytic pyrolysis reaction is carried out at a constant temperature of 750°C and a pressure of 0.1Mpa for 30min...

Embodiment 2

[0049] The biomass used in this example is corn stalks, and its industrial analysis and elemental analysis are shown in Table 1.

[0050] 1. Preparation of Fe / HZSM-5 catalyst

[0051] Immerse the iron nitrate nonahydrate solution on the HZSM-5 powder, soak it at room temperature for 24 hours, dry it at 80°C for 12 hours, bake it at 550°C for 6 hours, press it into tablets, and screen out 20-40 mesh particles to obtain Fe / HZSM-5 catalyst.

[0052] 2. Preparation of bio-oil by catalytic pyrolysis

[0053] (1) crush the corn stalks and pass through a 100-mesh sieve, and then mix the two according to the mass ratio of Fe / HZSM-5 catalyst: corn stalks=0.8:1 to obtain a mixture;

[0054] (2) Put the mixture in a fixed-bed pyrolysis reactor, feed methane gas from the inlet of the fixed-bed pyrolysis reactor at a gas flow rate of 36000ml / min, and carry out catalytic pyrolysis reaction at a constant temperature of 800°C and 3Mpa pressure for 200min ;

[0055] (3) The liquid products...

Embodiment 3

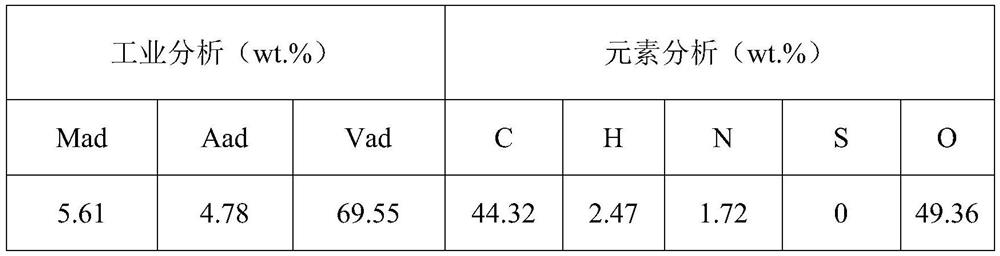

[0057] The biomass used in this example is wheat straw, and its industrial analysis and elemental analysis are shown in Table 2.

[0058] Table 2

[0059]

[0060] 1. Preparation of Fe / HZSM-5 catalyst

[0061] Immerse iron nitrate nonahydrate solution on HZSM-5 powder, soak at room temperature for 23 hours, dry at 79°C for 11 hours, bake at 545°C for 5.5 hours, form into tablets, screen out 20-40 mesh particles, and obtain Fe / HZSM-5 catalyst.

[0062] 2. Preparation of bio-oil by catalytic pyrolysis

[0063] (1) crush the corn stalks and pass through a 100-mesh sieve, and then mix the two according to the mass ratio of Fe / HZSM-5 catalyst: corn stalks=3:1 to obtain a mixture;

[0064] (2) The mixture is placed in a fixed-bed pyrolysis reactor, and natural gas is introduced from the inlet of the fixed-bed pyrolysis reactor at a gas flow rate of 10000ml / min, and the catalytic pyrolysis reaction is carried out at a constant temperature of 60min at 700°C and a pressure of 2Mp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com