Nano carbon material composite additive based on surface modification and preparation method thereof

A nano-carbon material and composite additive technology, applied in the nano field, can solve the problems such as the dispersion stability not reaching the desired effect, and achieve the effects of avoiding post-processing problems, reducing the usage amount, and improving the dispersion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

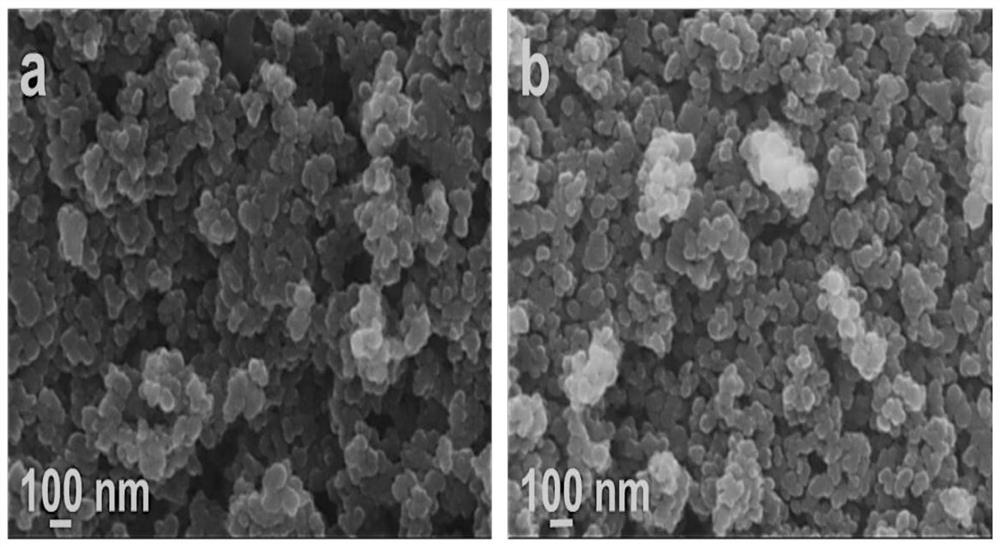

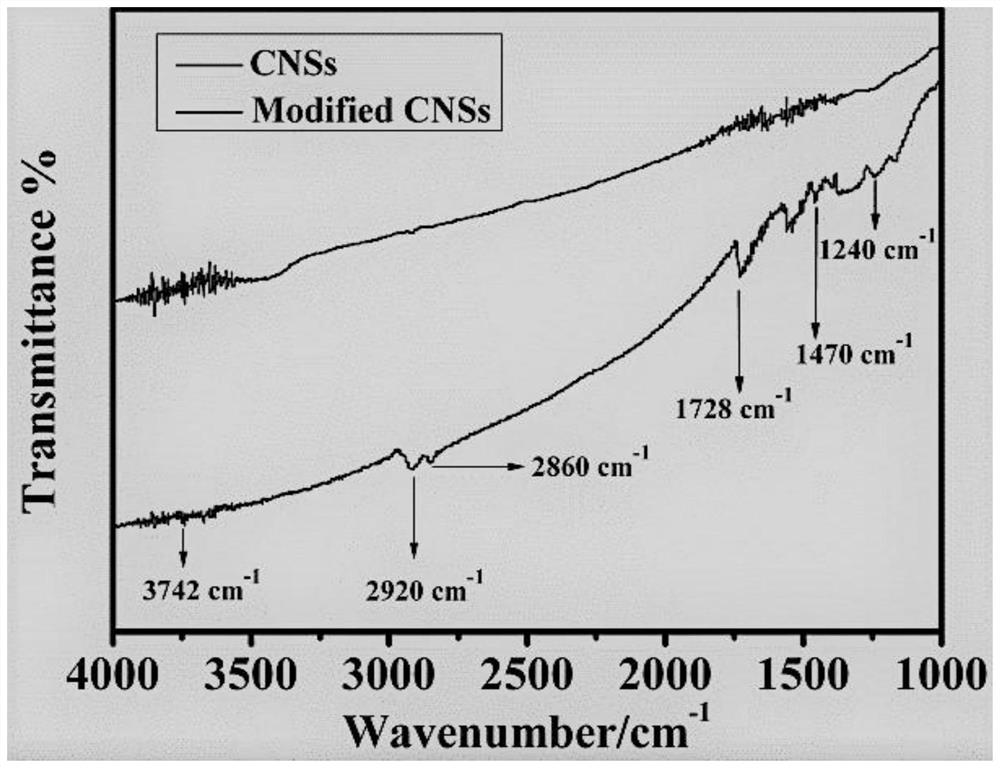

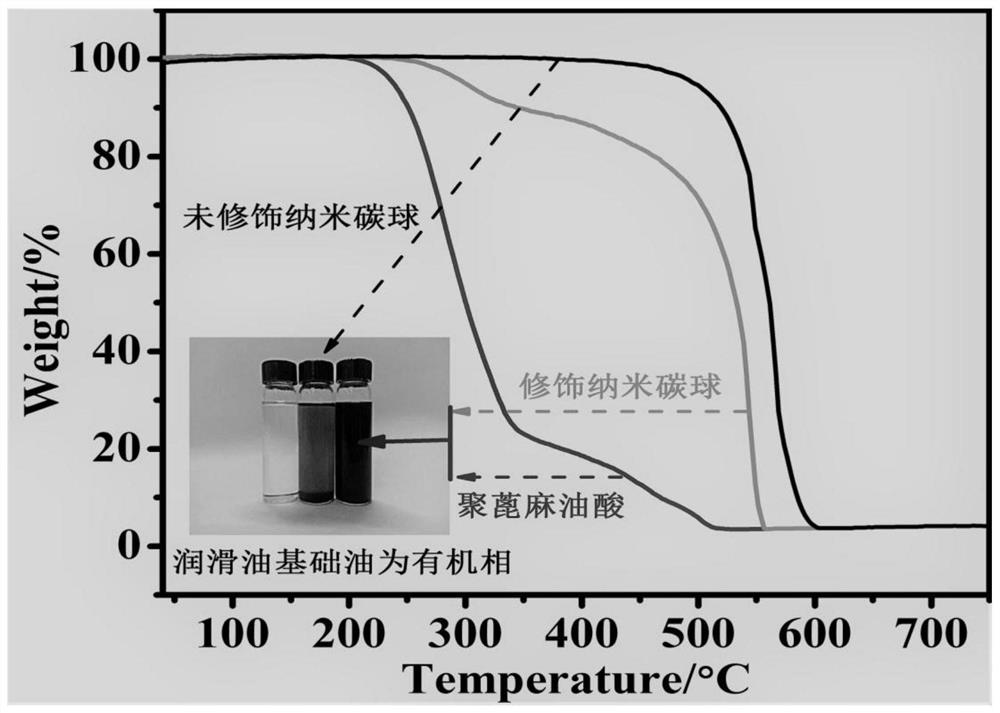

Image

Examples

Embodiment 1

[0061] A preparation method of a nano-carbon ball composite additive based on surface modification, comprising the following steps:

[0062] 1 g of acidified carbon nanospheres was added to 60 g of ricinoleic acid, and 0.09 g of catalyst zinc oxide was added. The reaction was carried out at 200° C. under vacuum conditions for 10 hours; after the reaction, it was naturally cooled, and after ultrasonic dispersion at room temperature for 15 minutes, the surface-modified nano-carbon material-ricinoleic acid composite anti-wear additive was obtained.

Embodiment 2

[0064] A method for preparing a carbon nanotube composite additive based on surface modification, comprising the following steps:

[0065] 1 g of acidified carbon nanotubes were added to 60 g of ricinoleic acid, and 0.09 g of catalyst zinc oxide was added. The reaction was carried out at 200° C. under vacuum conditions for 10 hours; after the reaction was completed, it was naturally cooled, and after ultrasonic dispersion at room temperature for 15 minutes, the surface-modified carbon nanotube-ricinoleic acid composite antiwear additive was obtained.

Embodiment 3

[0067] A preparation method of a graphene oxide composite additive based on surface modification, comprising the steps:

[0068] 1 g of acidified graphene oxide was added to 60 g of ricinoleic acid, and 0.09 g of catalyst zinc oxide was added. The reaction was carried out at 200° C. under vacuum conditions for 10 hours; after the reaction, it was naturally cooled, and after ultrasonic dispersion at room temperature for 15 minutes, the surface-modified graphene oxide-ricinoleic acid composite anti-wear additive was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com